Iron head

a technology of iron head and spherical head, which is applied in the field of iron head, can solve the problems of difficult to obtain a strong impact feeling, and achieve the effects of reducing the total weight of the iron head, enlarge the sweet area without increasing the total weight, and increasing the partial weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

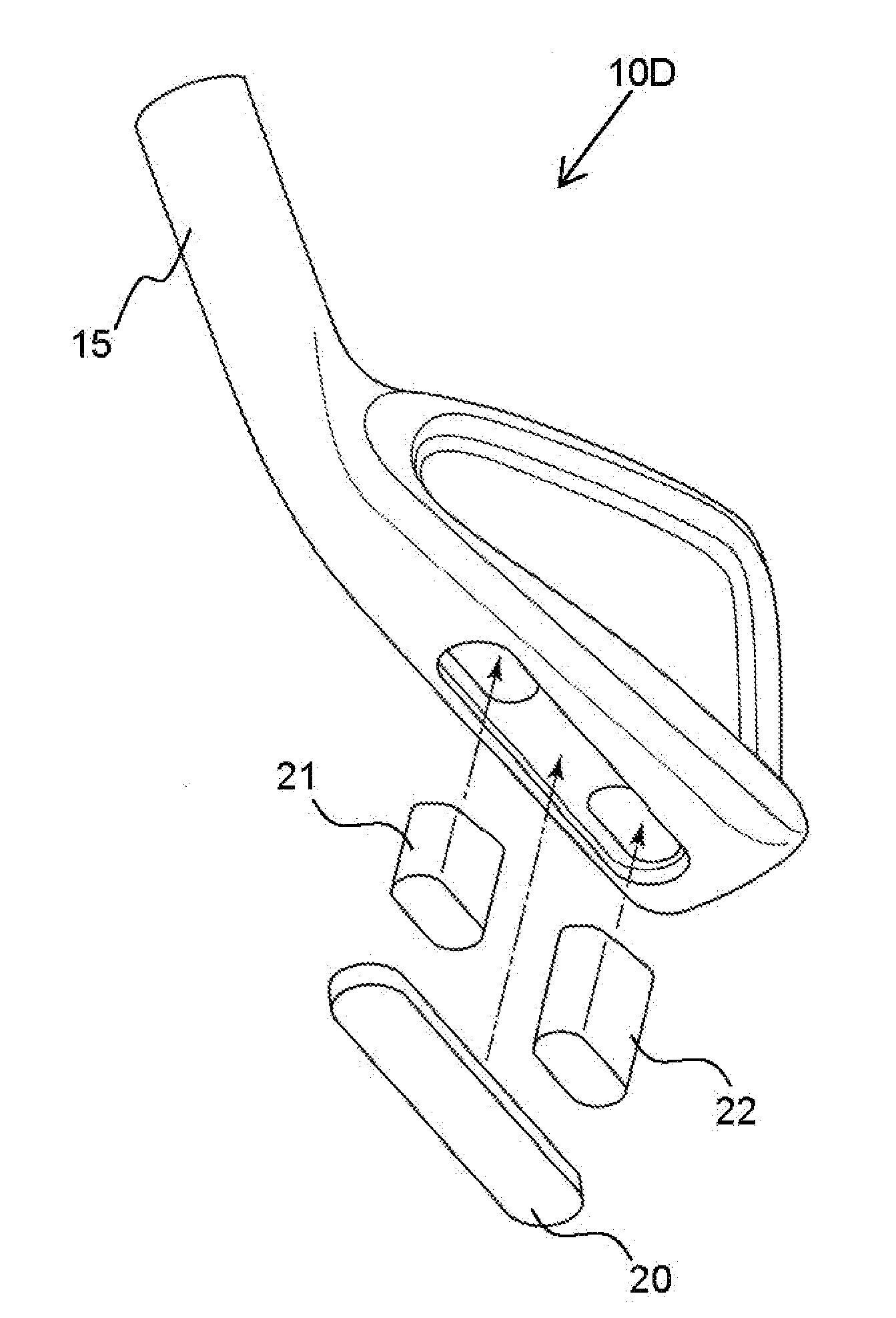

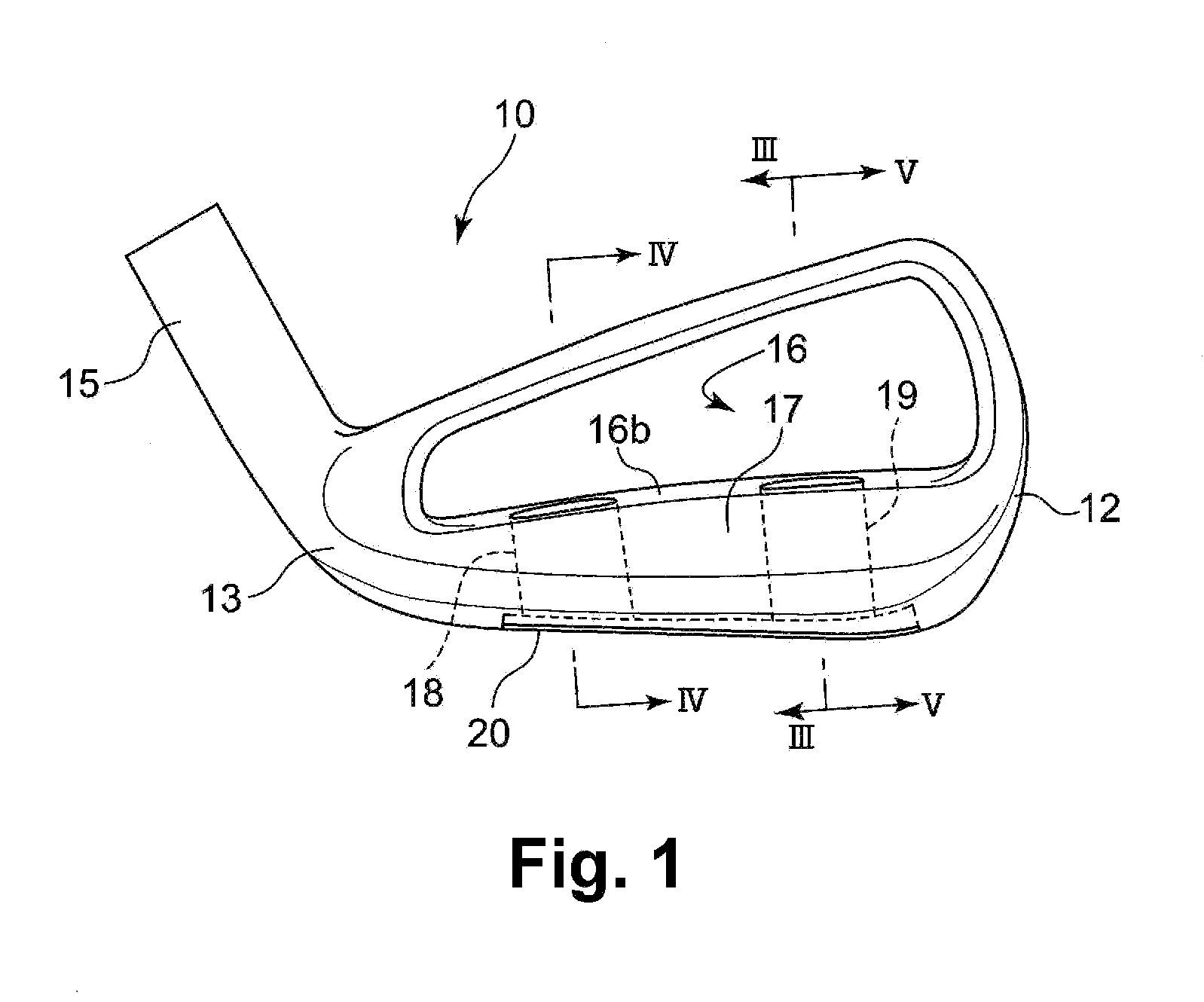

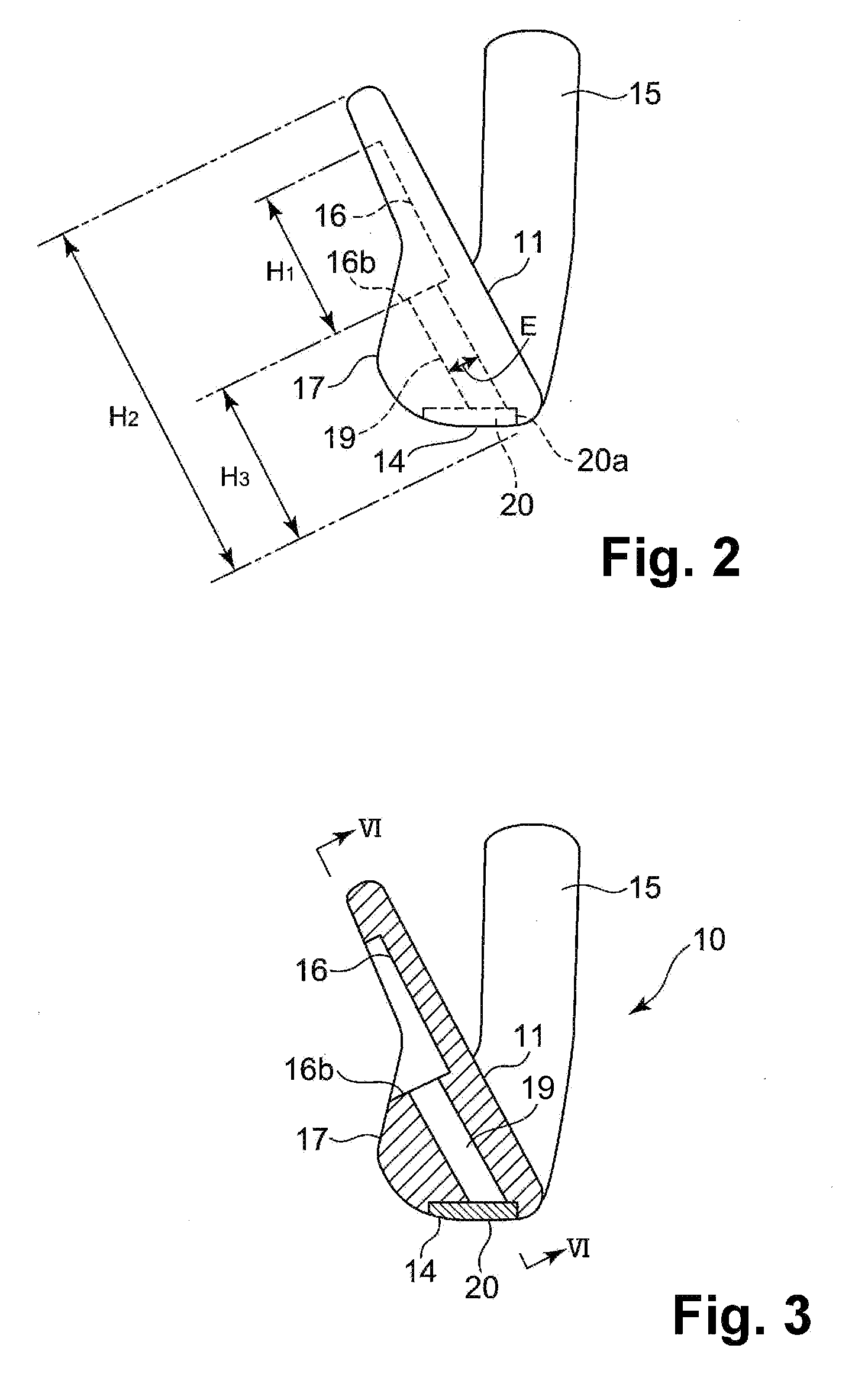

[0072]FIGS. 1 through 6 show an iron head 10 according to a first embodiment of the present invention. The iron head 10 is provided with a striking face 11 for hitting a ball, a toe side 12, a heel side 13, a sole surface 14, and a hosel 15 for connecting a shaft. Further, the iron head 10 is provided with a cavity portion 16 disposed in an upper portion of a backside surface thereof; a protruding portion 17 disposed at a lower portion of the backside surface thereof and projecting backward; a first hollow portion 18 disposed on the heel side 13 of the protruding portion 17 and penetrating from a bottom surface 16b of the cavity portion 16 to the sole surface 14; a second hollow portion 19 disposed on the toe side of the protruding portion 17; and a bottom lid 20 disposed on the sole surface to close the hollow portions 18 and 19.

[0073]As shown in FIG. 6, the cavity portion 16 is recessed from a rear side of the iron head to the striking surface side thereof not only at an upper edg...

second embodiment

[0083]FIGS. 7 and 8 show an iron head 10A according to the second embodiment of the present invention. According to the first embodiment, the width W1 of the middle portion M in the toe to heel direction is substantially same from the upper end thereof to the lower end thereof. According to the second embodiment, instead of the hollow portions 18 and 19 in the first embodiment, the iron head 10A is provided with a hollow portion 18A disposed away from a hollow portion 19A by a distance gradually increasing from the upper surface of the protruding portion toward the sole surface.

[0084]It is desirable that the hollow portion 18A and the hollow portion 19A have a distance therebetween, at the top end thereof, being same as the width W1 mentioned above. Further, at the bottom end, it is desirable that the distance between the hollow portion 18A and the hollow portion 19A is equal to or less than 1.2 times, especially equal to or less than 1.1 times, of the distance between the hollow po...

third embodiment

[0085]In the first and second embodiments, the hollow portions 18, 19, 18A, and 19A have a width E, which is the thickness thereof in the vertical direction to the face surface. The width E is substantially same from the top end to the bottom end of the hollow portions 18, 19, 18A, and 19A. As shown in FIG. 9, in an iron head 10B according to the third embodiment, each of hollow portions 18B (not shown) and 19B has a thickness gradually increasing from the top end of the hollow portions toward the bottom end thereof. Further, the hollow portions 18B and 19B have a thickness, at the upper end thereof, being same as the width E in the first and second embodiments. It is desirable that the thickness of the bottom end of the hollow portions 18B and 19B is equal to or less than twice, especially equal to or less than 1.2 times, of that of the upper end thereof. Other configurations of the third embodiment are same as the first embodiment, and same reference numerals denote same component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com