Meta-material vibration energy harvester

a technology of vibration energy harvester and metal material, which is applied in the direction of dynamo-electric machines, dynamo-electric components, electrical apparatus, etc., can solve the problems of increasing noise and microclimate change, limited energy harvesting potential, and limited efficiency of existing technologies, and achieves the effect of strengthening the viscous damper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

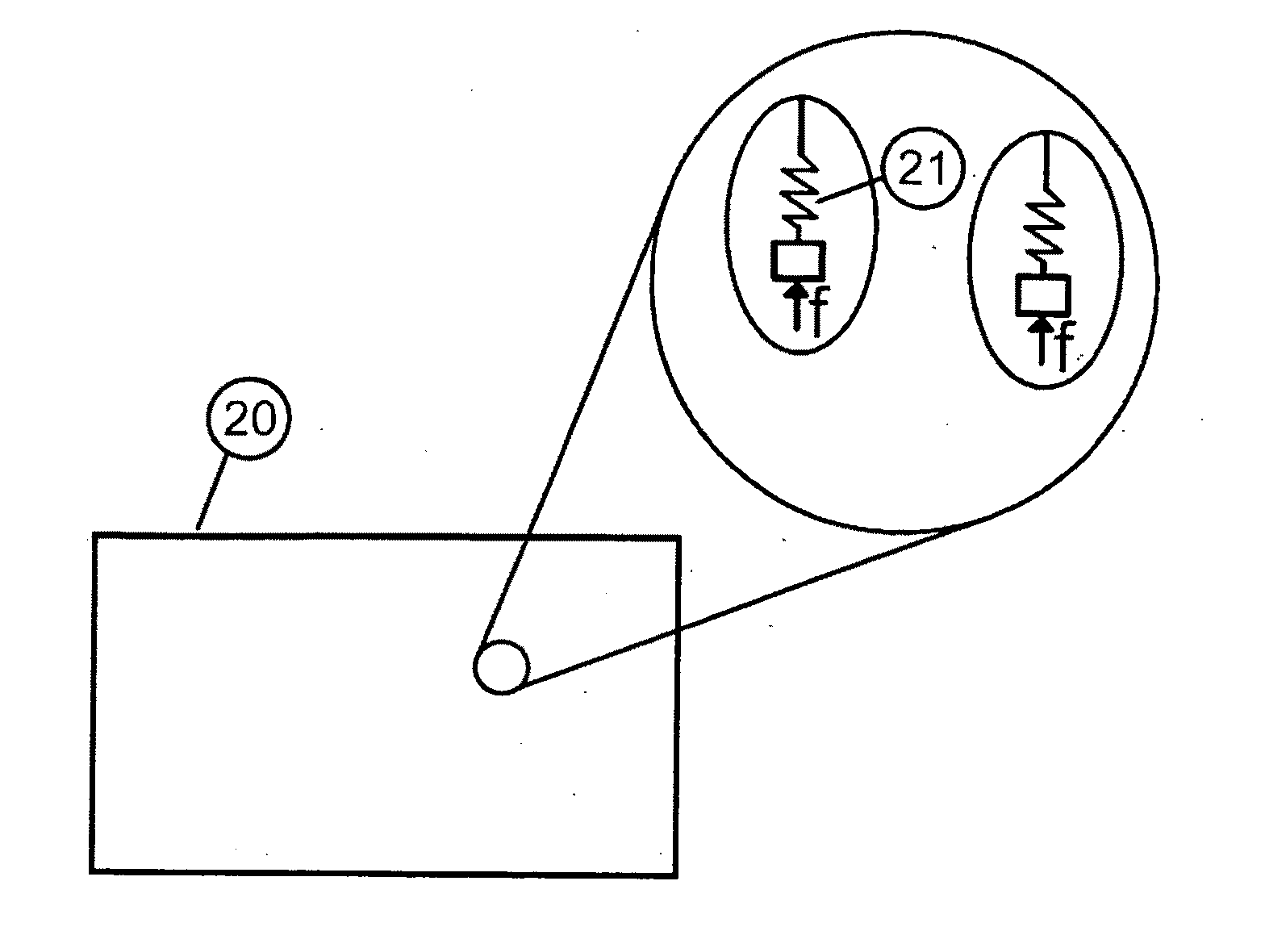

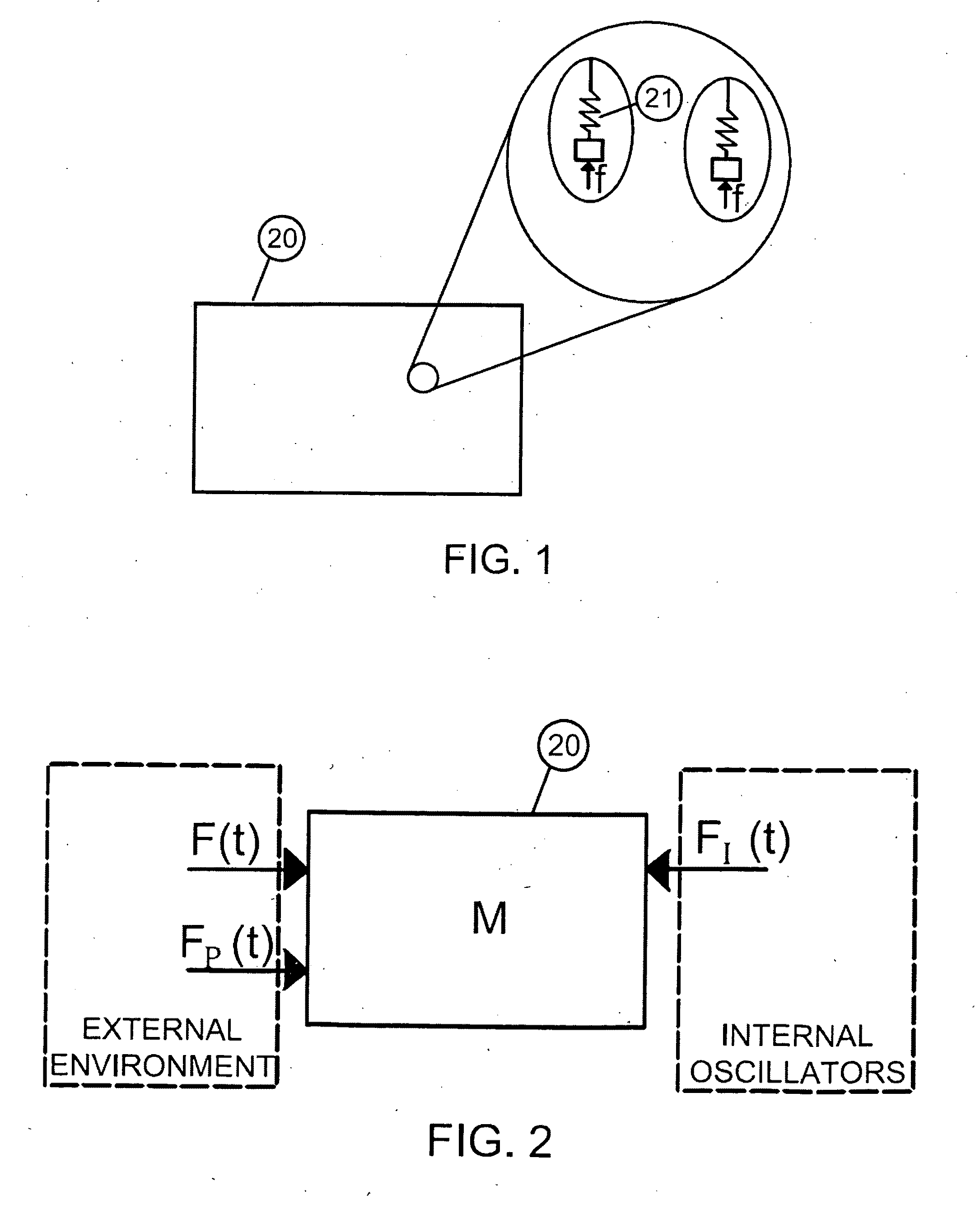

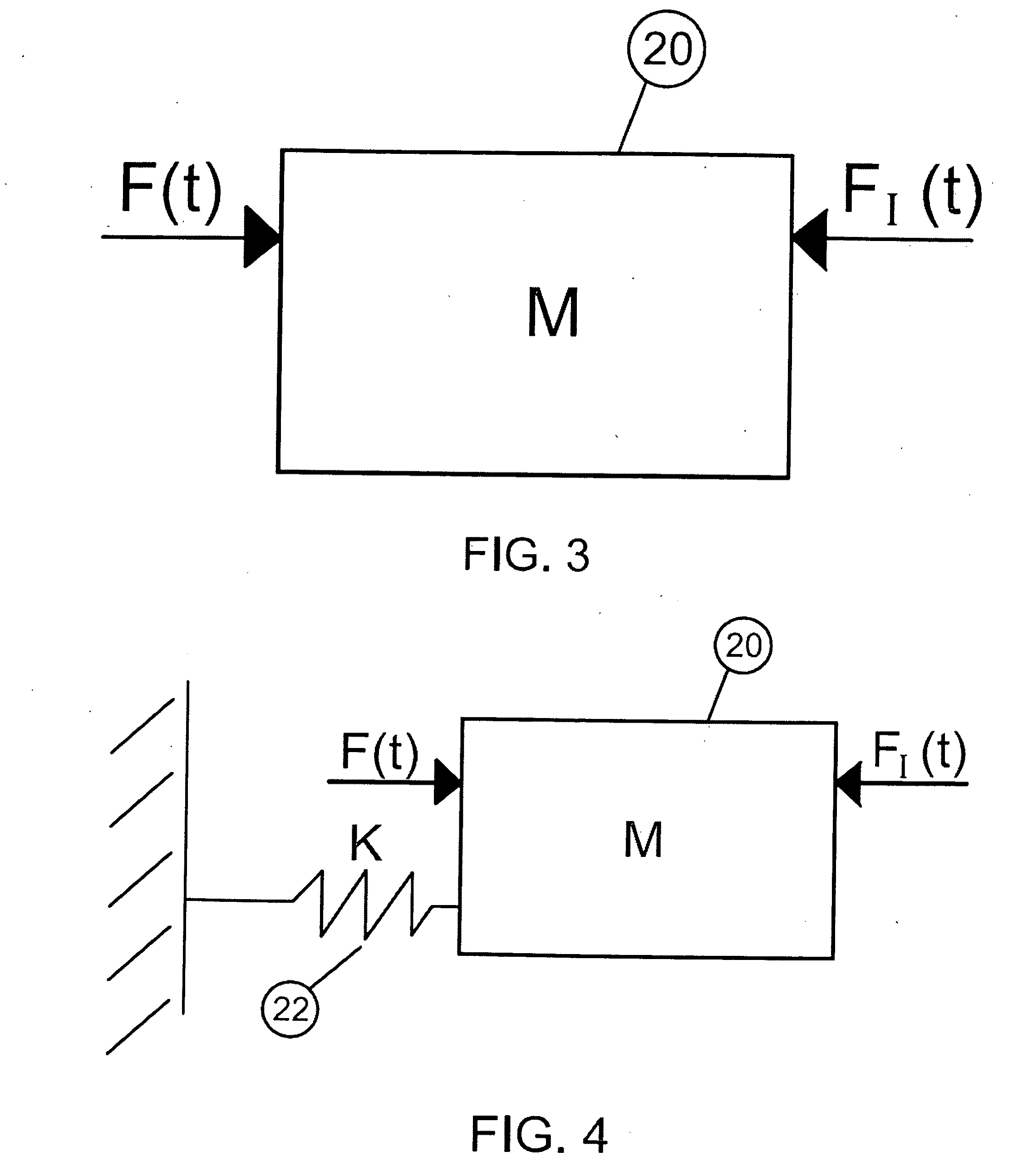

[0042]The novelty of the concept of meta-material devices, as described in the summary description, and the paucity of studies reported in the literature, which directly apply to the invention necessitates a highly technical detailed description. The description is presented in stages, focusing first on the energetics of a “mechanical” meta-material (MMM) device that forms the genesis of the invention, and, second, on the energetics of a “meta-material mechanical / electrical energy converter” (MMMEEC) in the context of an experiment scenario that has a direct relation to energy harvesting. When joined to a VS, which is the source of input energy to the MMMEEC, the device is a MMVEH. Issues related to the geometry and composition of the VS and to the coherence of the vibration field and the role of these in determining an effective MMVEH design are addressed at this point in the detailed description.

[0043]Additional sections in the detailed description describe different type attachme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com