Radial Compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

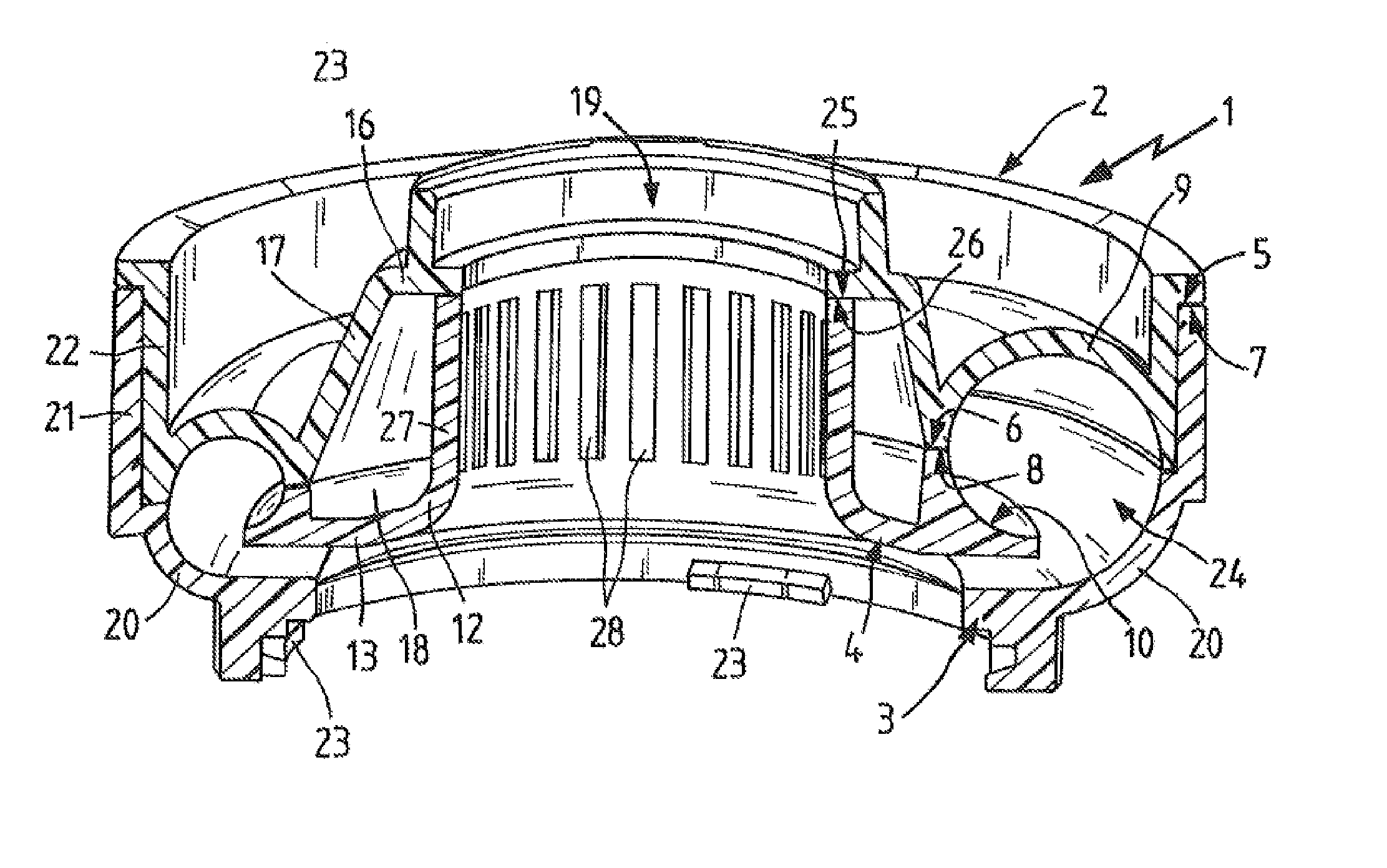

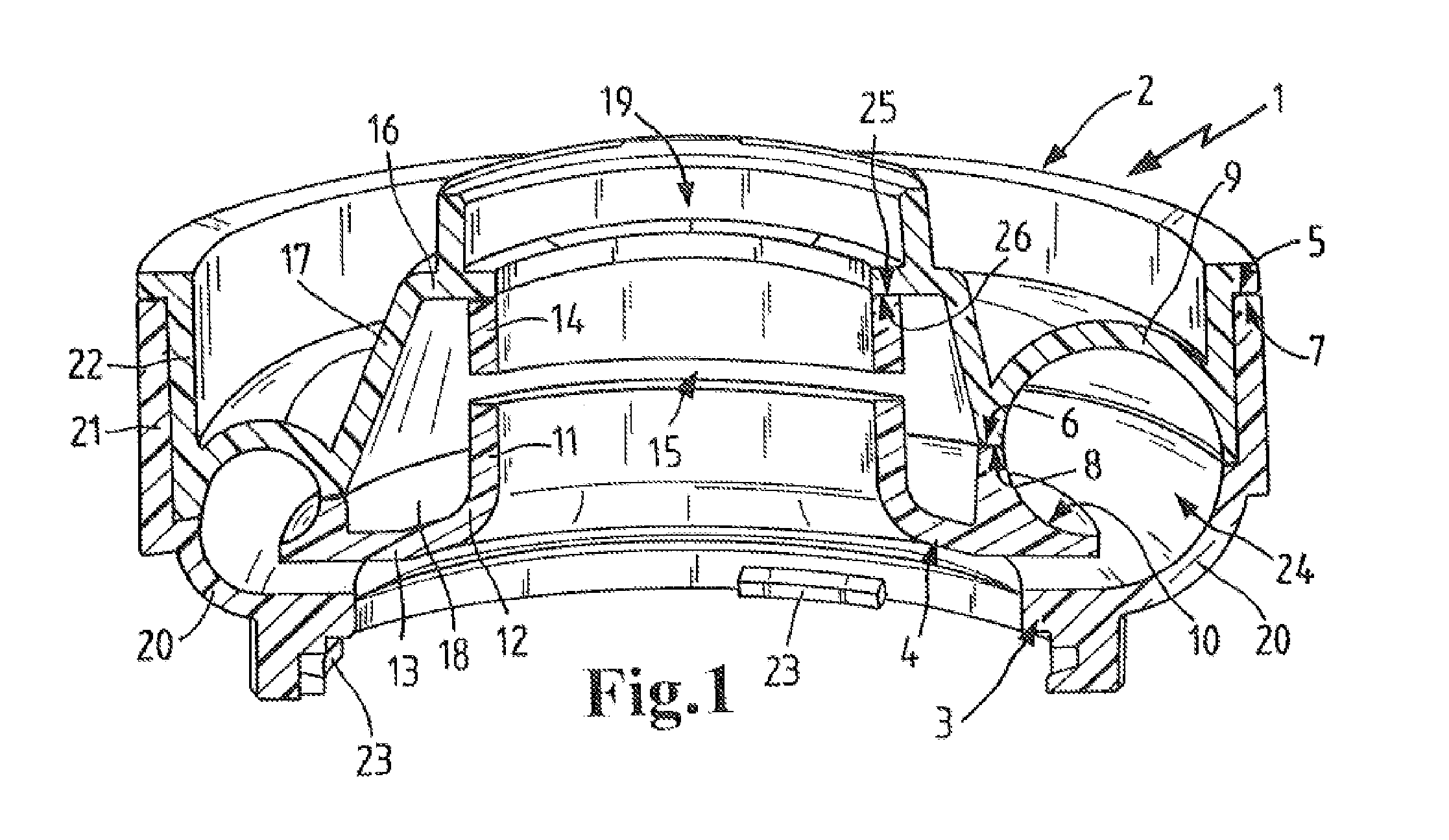

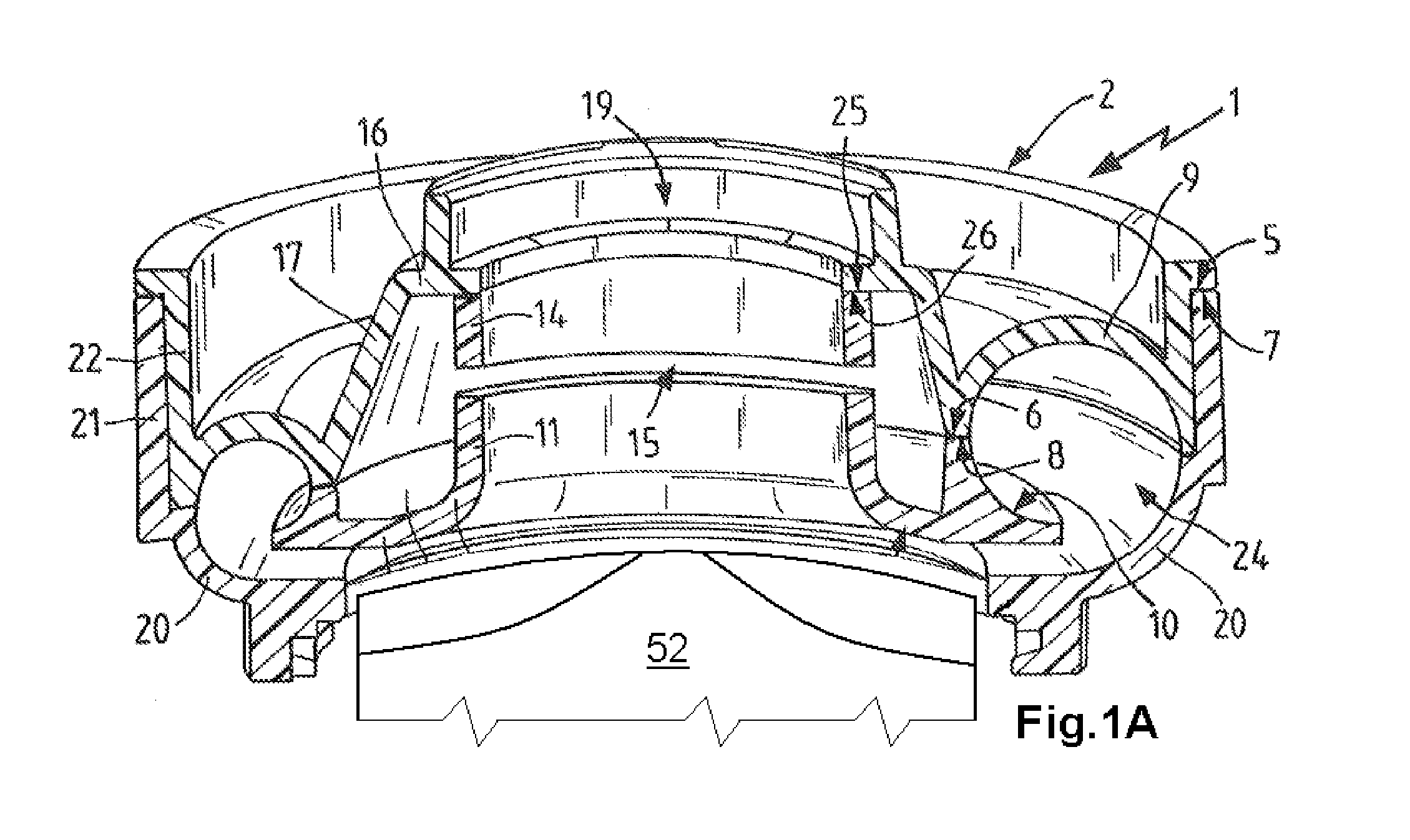

[0021]FIG. 1 shows a housing 1 that is comprised of three housing parts wherein between the top part 2 and the bottom part 3 a central part 4 is arranged. These housing parts 2, 3, 4 are comprised of a thermoplastic synthetic material, for example, PPS (polyphenyl sulfide). On the top part 2 there are two annular joining or connecting surfaces 5, 6 wherein on the connecting surface 5 an end face 7 of the bottom part 3 and on the connecting surface 6 a contact surface 8 of the central part 4 are resting. The connecting surface 5 and the end face 7 as well as the connecting surface 6 and the contact surface 8 form welding zones, respectively, where the parts are integrally joined or bonded. FIG. 1A shows the radial compressor housing of FIG. 1 including a schematic depiction of a compressor wheel 52 rotatably supported in the housing.

[0022]On the top part 2 a curved portion 9 that is open in downward direction is formed that extends in an annular shape and is widening in the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com