Heat-conductive noise suppression sheet

a technology of heat-conductive and noise suppression, which is applied in the direction of magnetic/electric field screening, solid-state devices, and semiconductor/solid-state device details. it can solve the problems of ineffective increase of thermal conductivity, difficulty in effective increase of noise suppression effect in the hundred megahertz range, and in the gigahertz range. achieve high noise suppression effect and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

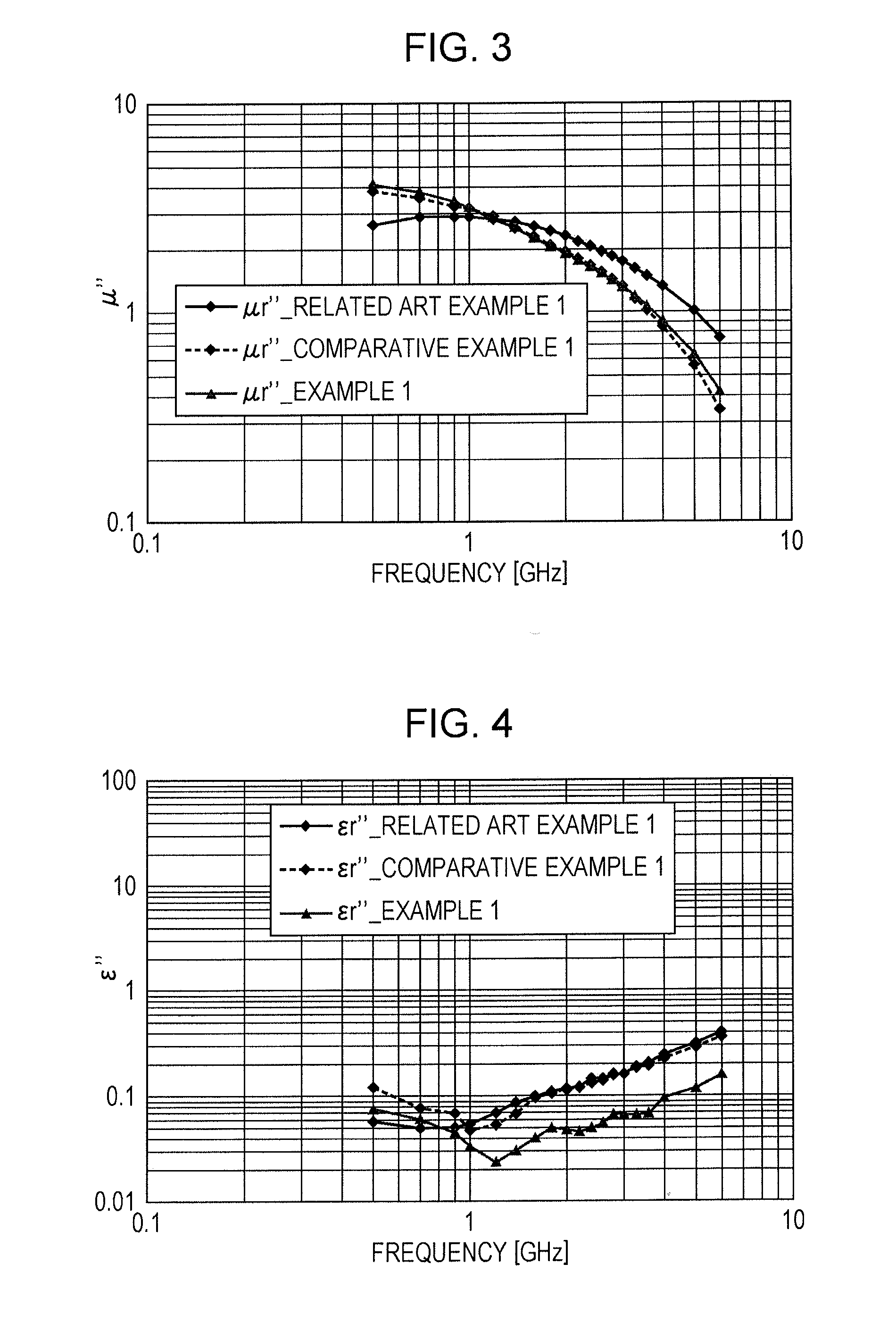

example 1

Related-Art Example 1

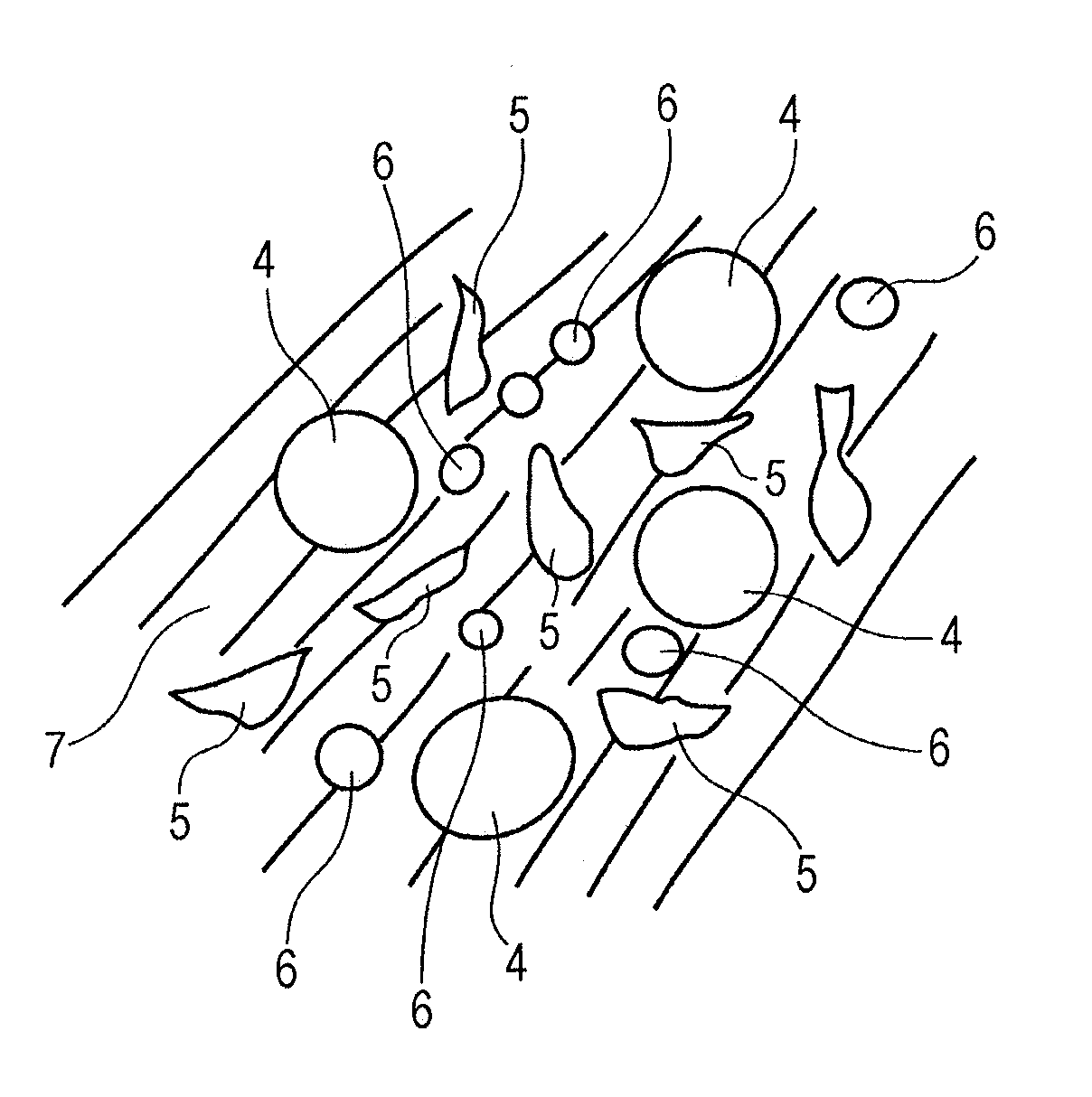

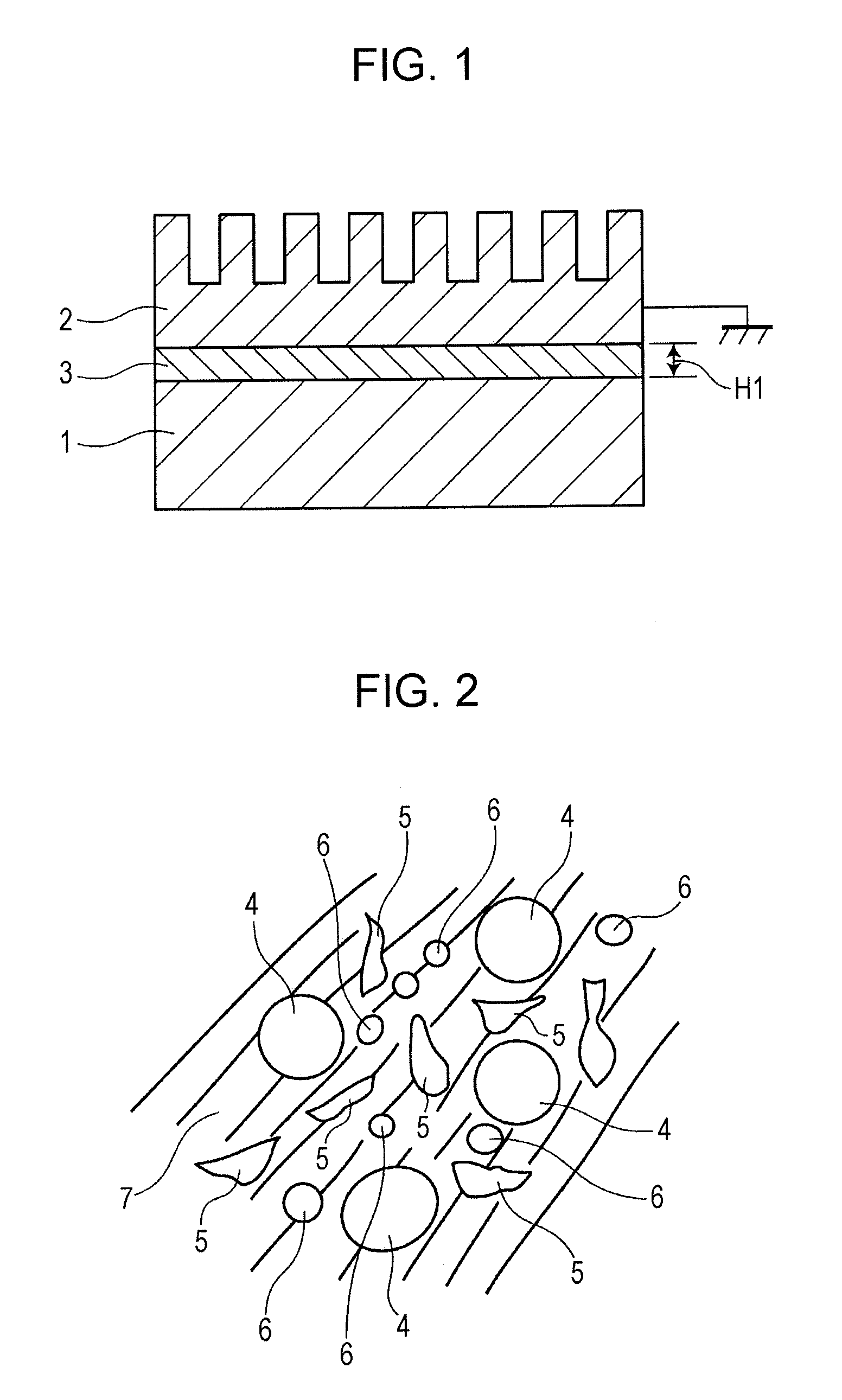

[0071]E7000K manufactured by Sony Chemical Corporation was used. It was found by analysis that the heat-conductive noise suppression sheet of Related-Art Example 1 contained Ni—Zn ferrite particles, aluminum oxide particles, and silicone gel. FIG. 7 is a cross-sectional photograph (SEM photograph) of the heat-conductive noise suppression sheet according to Related-Art Example 1. It is clear from FIG. 7 that the Ni—Zn ferrite particles are irregularly shaped particles that correspond to the second ferrite particles according to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| average particle diameter | aaaaa | aaaaa |

| average particle diameter | aaaaa | aaaaa |

| average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com