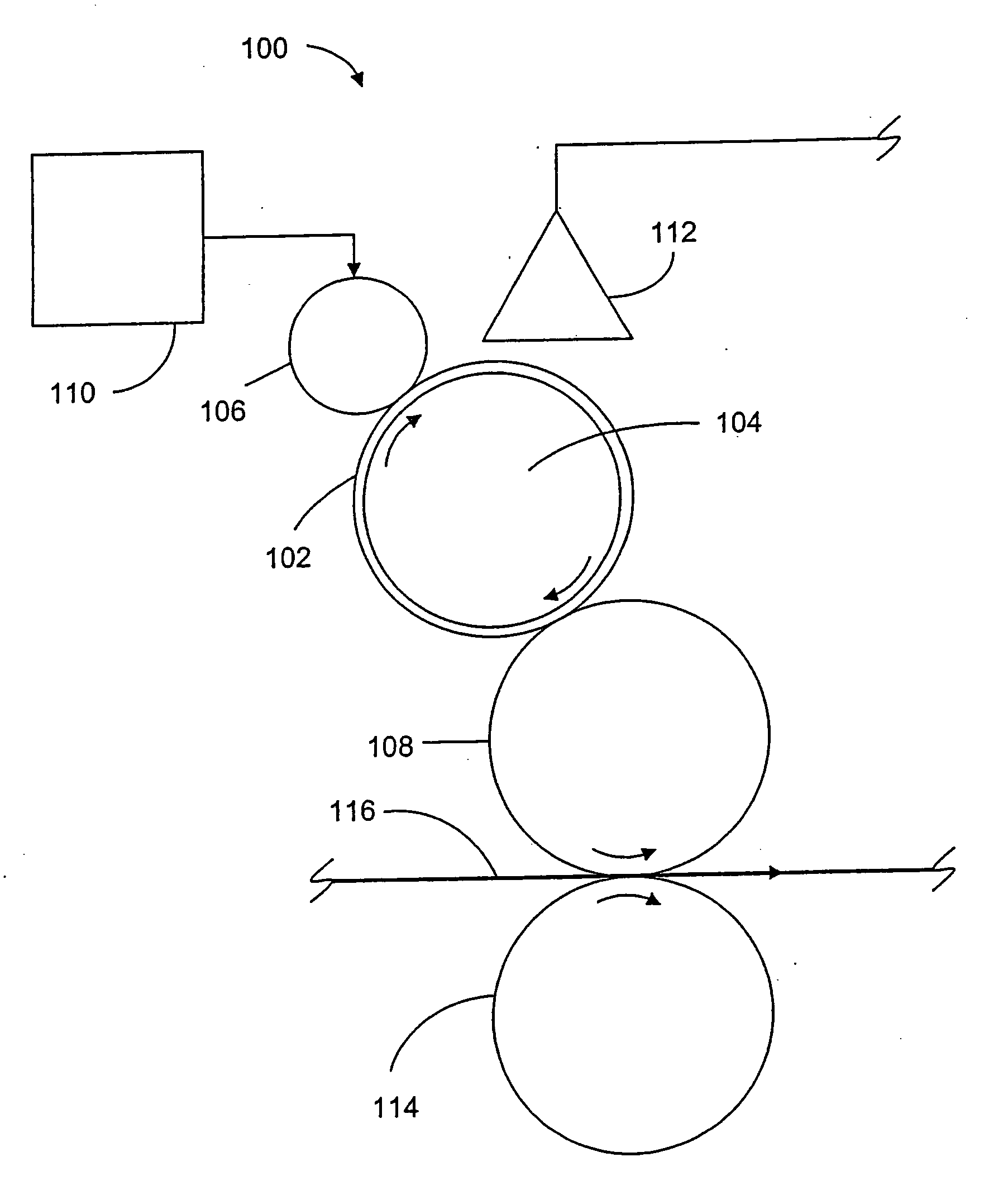

Lithographic printing press for processless plate

a technology of processless plates and printing presses, applied in the field of magnification of lithographic plates, to achieve the effects of reducing incident dissolution, reducing the number of lithographic plates, and improving the adhesion and cohesion of imaged areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0056]In a first trial at a commercial newspaper printing facility, a negative working, photopolymerizable plate was imaged with IR radiation at 90 mj / cm2 and developed on press during startup as described above, then used in the normal manner to print over 100,000 high quality newspaper sheets. The plate was constituted as follows:

[0057](a) grained, hydrophilized aluminum substrate

[0058](b) imagable coating comprising the raw materials[0059](i) organic solvent[0060](ii) polyvinyl butyral polymer resin[0061](iii) penta functional acrylate monomer[0062](iv) pigment dispersion[0063](v) stabilizer[0064](vi) IR dye[0065](vii) organo-borate catalyst[0066](vii) onium salt catalyst[0067](viii) partially water soluble additive (DTTDA)

[0068](c) PVOH topcoat

[0069]After thermal imaging, the plate was post-heated. It is believed this step produces further cross linking in the imaged areas but not in the unimaged areas. After cooling, the topcoat was washed off with tap water. Several hours afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| cohesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com