Size scaling of a burner

a burner and scale technology, applied in the field of square burners, can solve the problems of unsteady fluid dynamic process, thermo-acoustic instabilities, movement of flames, etc., and achieve the effect of rapid and stable combustion of the main lean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]In the following a number of embodiments will be described in more detail with references to the enclosed drawings.

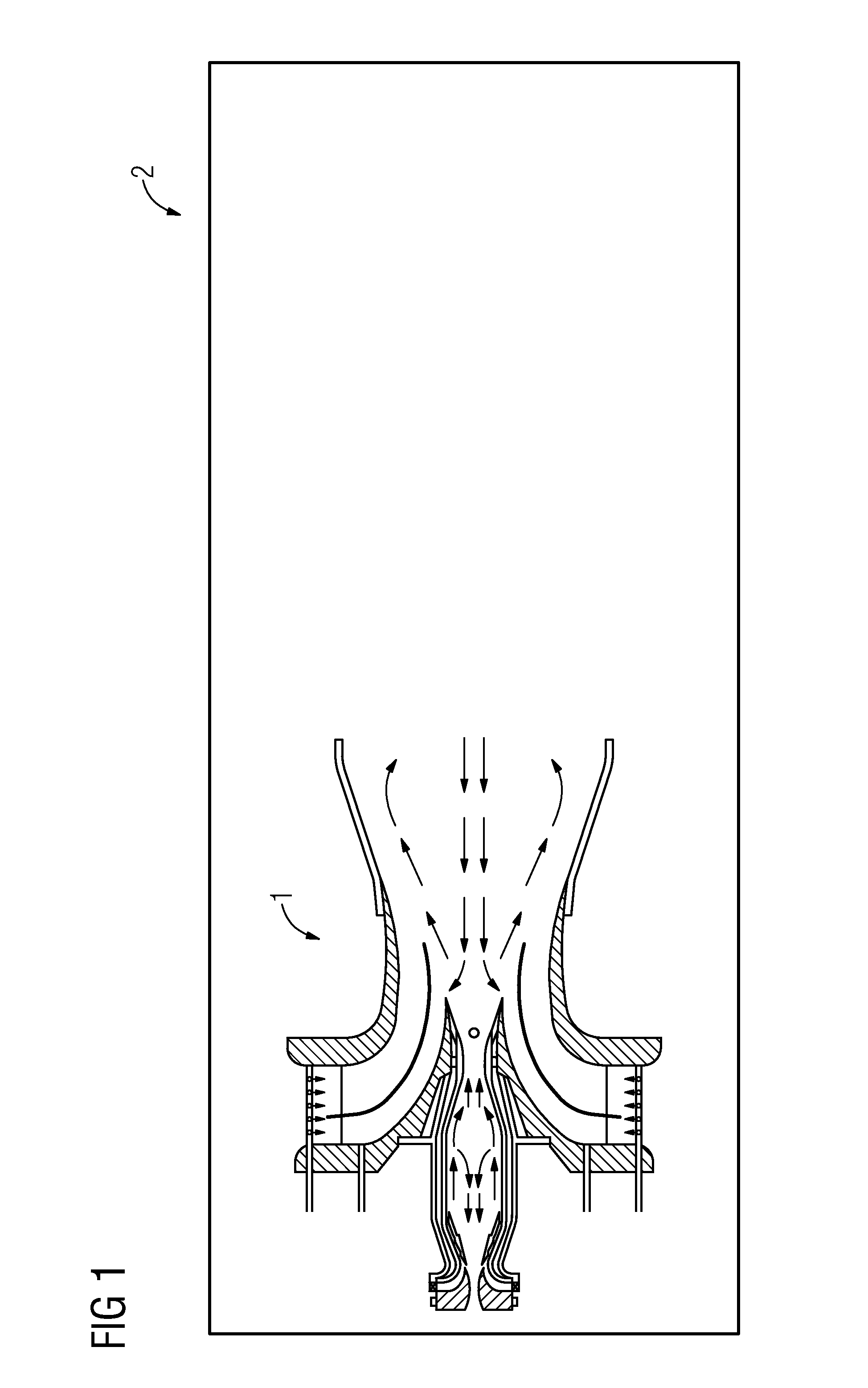

[0041]In FIG. 1 the burner is depicted with the burner 1 having a housing 2 enclosing the burner components.

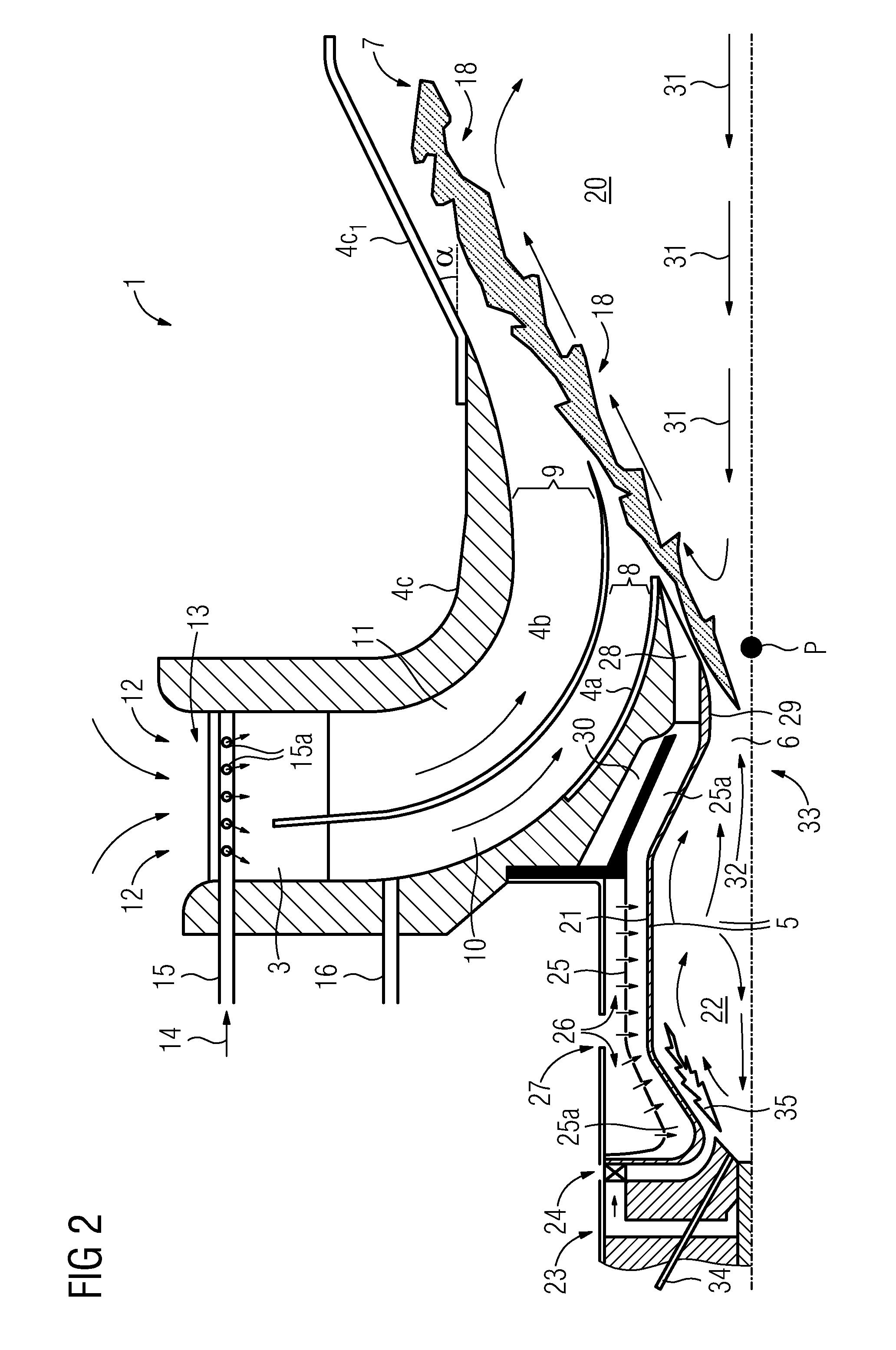

[0042]FIG. 2 shows for the sake of clarity a cross sectional view of the burner above a rotational symmetry axis. The main parts of the burner are the radial swirler 3, the multi quarl 4a, 4b, 4c and the pilot combustor 5.

[0043]As stated, the burner 1 operates according to the principle of “supplying” heat and high concentration of free radicals from the a pilot combustor 5 exhaust 6 to a main flame 7 burning in a lean premixed air / fuel swirl emerging from a first exit 8 of a first lean premixing channel 10 and from a second exit 9 of a second lean premixing channel 11, whereby a rapid and stable combustion of the main lean premixed flame 7 is supported. Said first lean premixing channel 10 is formed by and between the walls 4a and 4b of the multi quarl. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com