Wire reel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

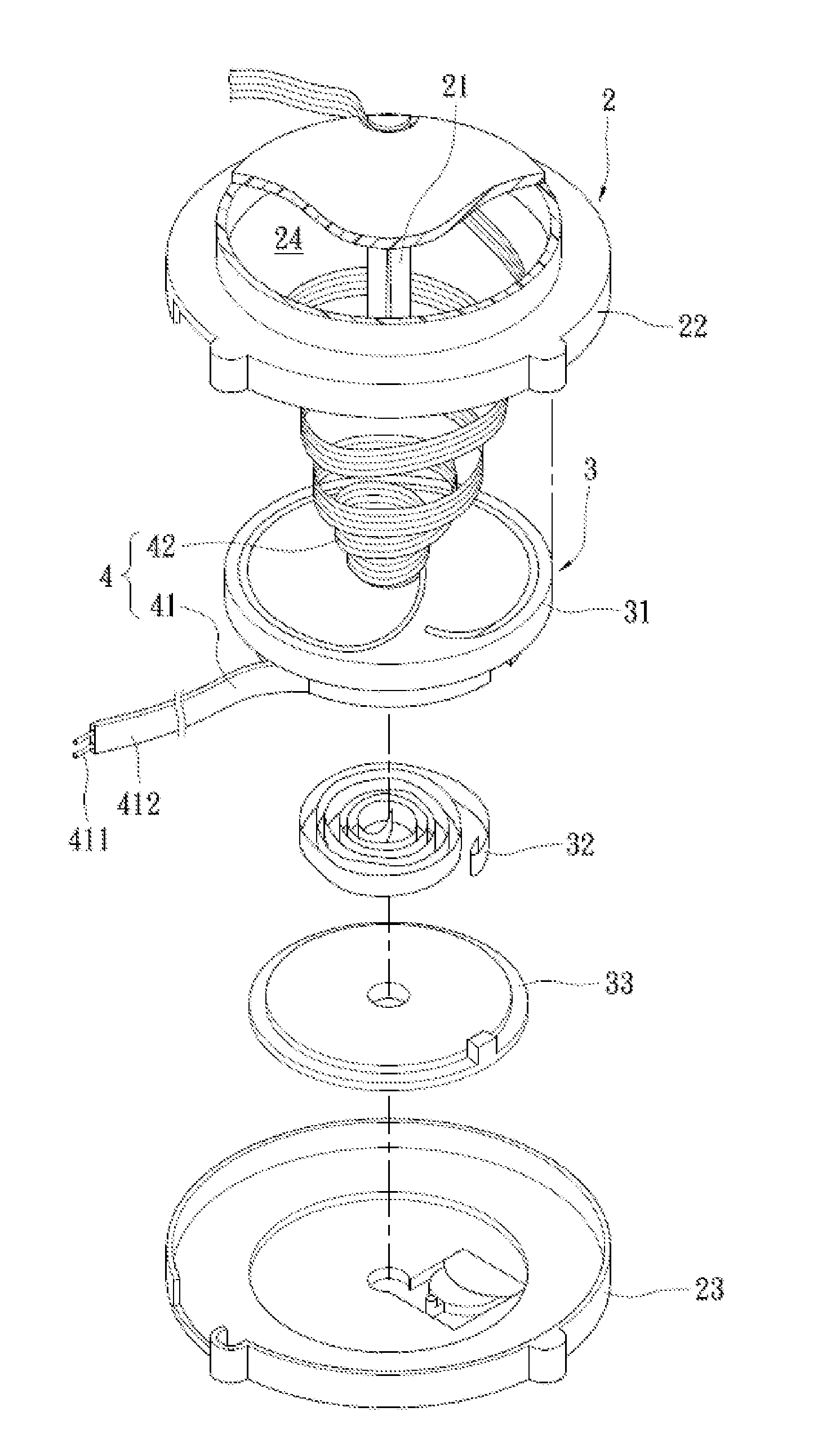

[0019]With reference to FIG. 4 for a wire reel structure of the present invention, the wire reel structure comprises a casing body 2, a reel unit 3 and a signal line unit 4.

[0020]The casing body 2 includes a central pillar 21 installed therein, and further includes a first casing 22 and a second casing 23 engaged with each other, wherein central pillar 21 is formed by extending from either the first casing 22 or the second casing 23.

[0021]The reel unit 3 is contained in the casing body 2, and the central pillar 21 is passed through the reel unit 3. The reel unit 3 includes a turntable 31, a coil spring 32 contained in the turntable 31, and a cover disc 33 covered onto the turntable 31, wherein an external end portion of the coil spring 32 is latched to the turntable 31, and an internal end portion of the coil spring 32 is latched to the central pillar 21 for driving the turntable 31 to rotate automatically. The central pillar 21 is passed through the turntable 31, the coil spring 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com