Real Time Pump Monitoring

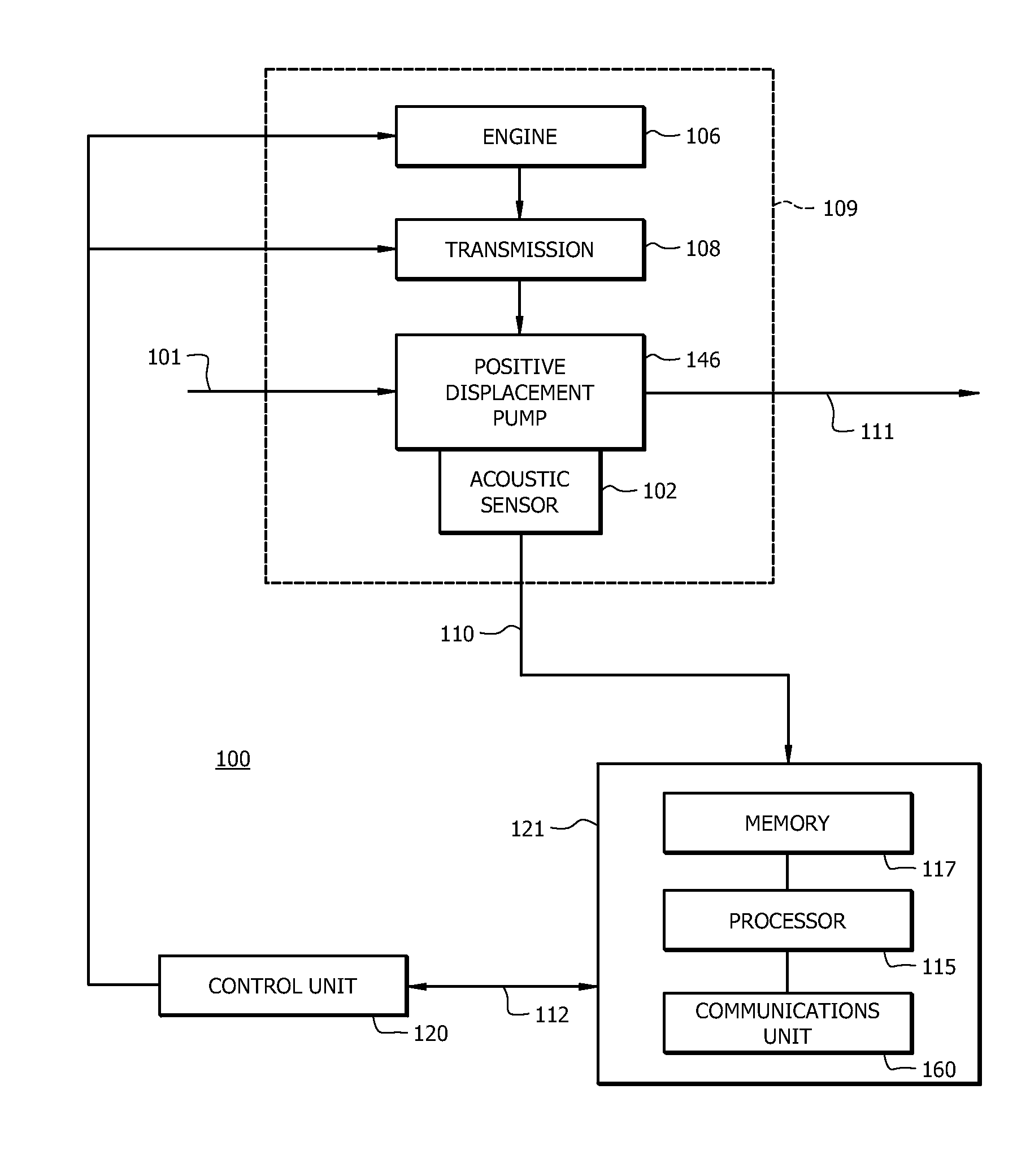

a real-time pump and monitoring technology, applied in the field of pumps, can solve the problems of unscheduled shutdown of wellbore service, increased probability of unscheduled shutdown, and catastrophic failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

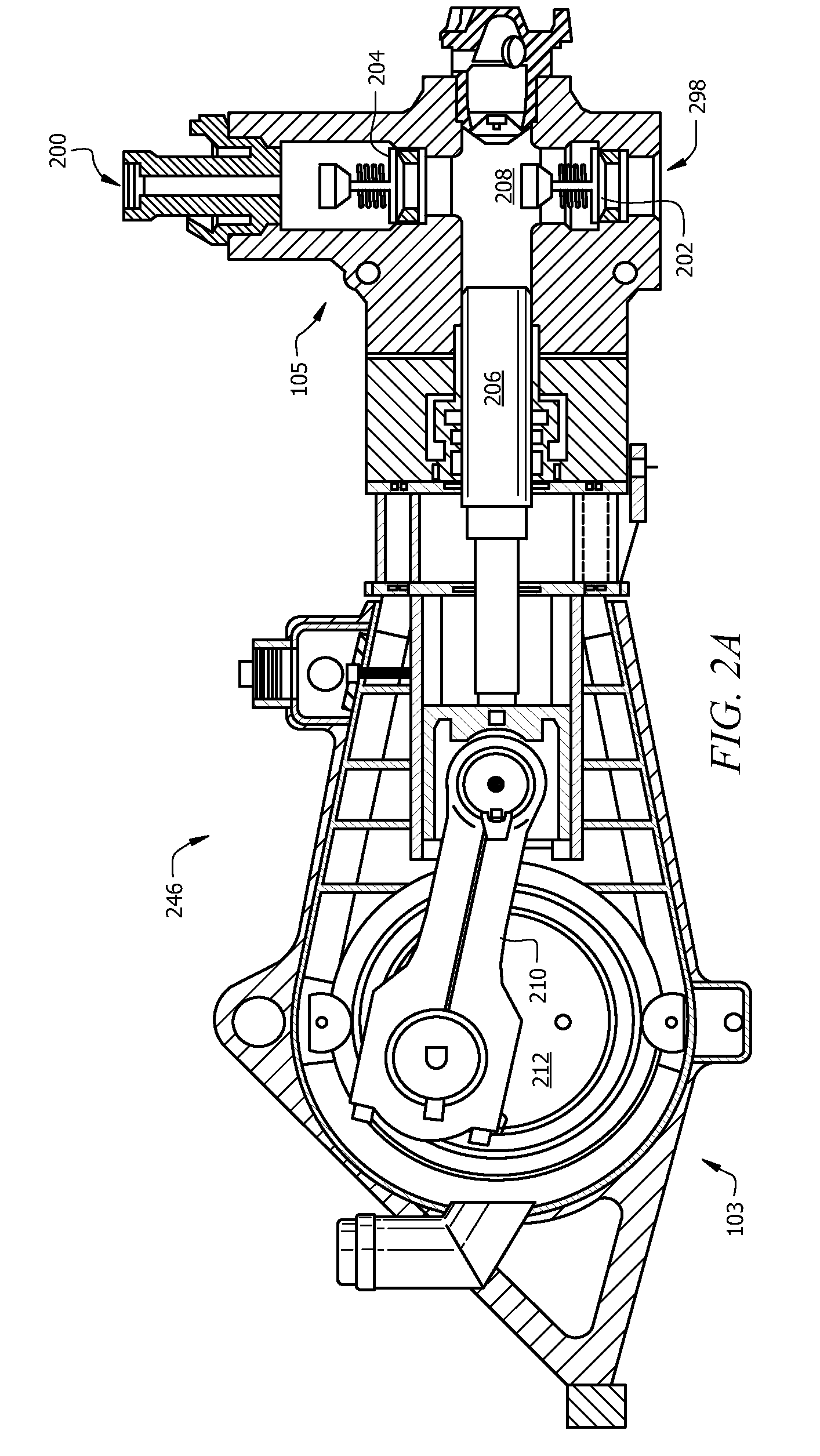

[0051]While operating the pump in gears 3-6 as set forth in Table 1, data was collected from the knock sensor and plotted in FIGS. 8-11, respectively. The strip charts (i.e., the lower plots so labeled) in FIGS. 8-11 represent a plot of RMS g's over a test period of time for operation in gears 3-6, respectively. Within the test period for a given gear, power spectrum analysis (as represented by the upper plots so labeled in FIGS. 8-11) was performed via FFT at various time intervals and plotted as RMS g's as a function of frequency from 0 to 5000 Hz. During the test period, pump speed was increased for each gear and cavitation was induced in the pump by restricting fluid flow to the pump by partially closing a valve in the suction side flow line to the pump.

[0052]Referring to FIG. 8, the pump was operated for a test period of about 150 seconds in gear 3. From about 0 to about 47 seconds of the test period, the pump was operating in gear 3 at lower rpms (e.g., about 100 rpm...

example 2

Leaky Suction Valve

[0062]Valve leakage was reproduced by placing a known leaky suction valve in one of the chambers of the three chamber pump. While operating the pump in gears 3-6 as set forth in Table 1, data was collected from the knock sensor and plotted in FIGS. 12-15, respectively. The strip charts in FIGS. 12-15 represent a plot of RMS g's over a test period of time for operation in gears 3-6, respectively. Within the test period for a given gear, power spectrum analysis (as represented by the upper plots so labeled in FIGS. 12-15) was performed via FFT at various time intervals and plotted as RMS g's as a function of frequency from 0 to 5000 Hz.

[0063]Referring to FIG. 12, the pump was operated for a test period of about 60 seconds in gear 3 at about 150 rpm. The strip chart of FIG. 12 shows g's ranging from about 3 to about 5 (alternatively, from about 3.5 to about 4.5 g's, alternatively equal to or greater than about 4 g's) during this period, which may be associated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com