Alternative I-Stud

a technology of i-studs and i-flanges, which is applied in the direction of girders, building repairs, walls, etc., can solve the problems of not meeting the need for an improved stud, requiring both additional materials and additional labor, and none of these products, etc., to achieve the effect of preventing microbial growth, reducing the cost of microbial growth, and reliably straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]While the making and using of various embodiments of the present disclosure are discussed in detail below, it should be appreciated that the present disclosure provides for inventive concepts capable of being embodied in a variety of specific contexts. The specific embodiments discussed herein are merely illustrative of specific manners in which to make and use the disclosed apparatus and are not to be interpreted as limiting the scope of the instant disclosure.

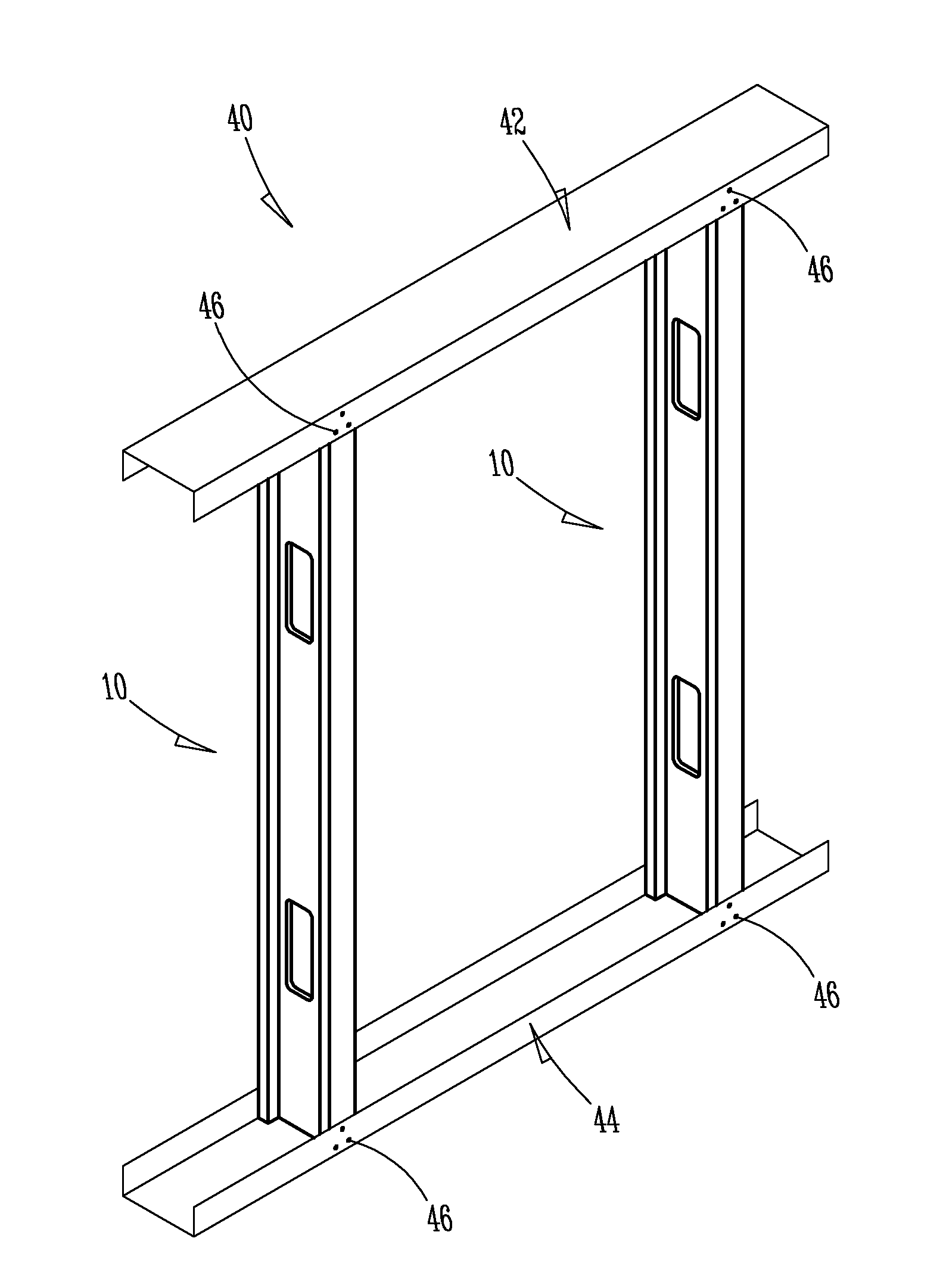

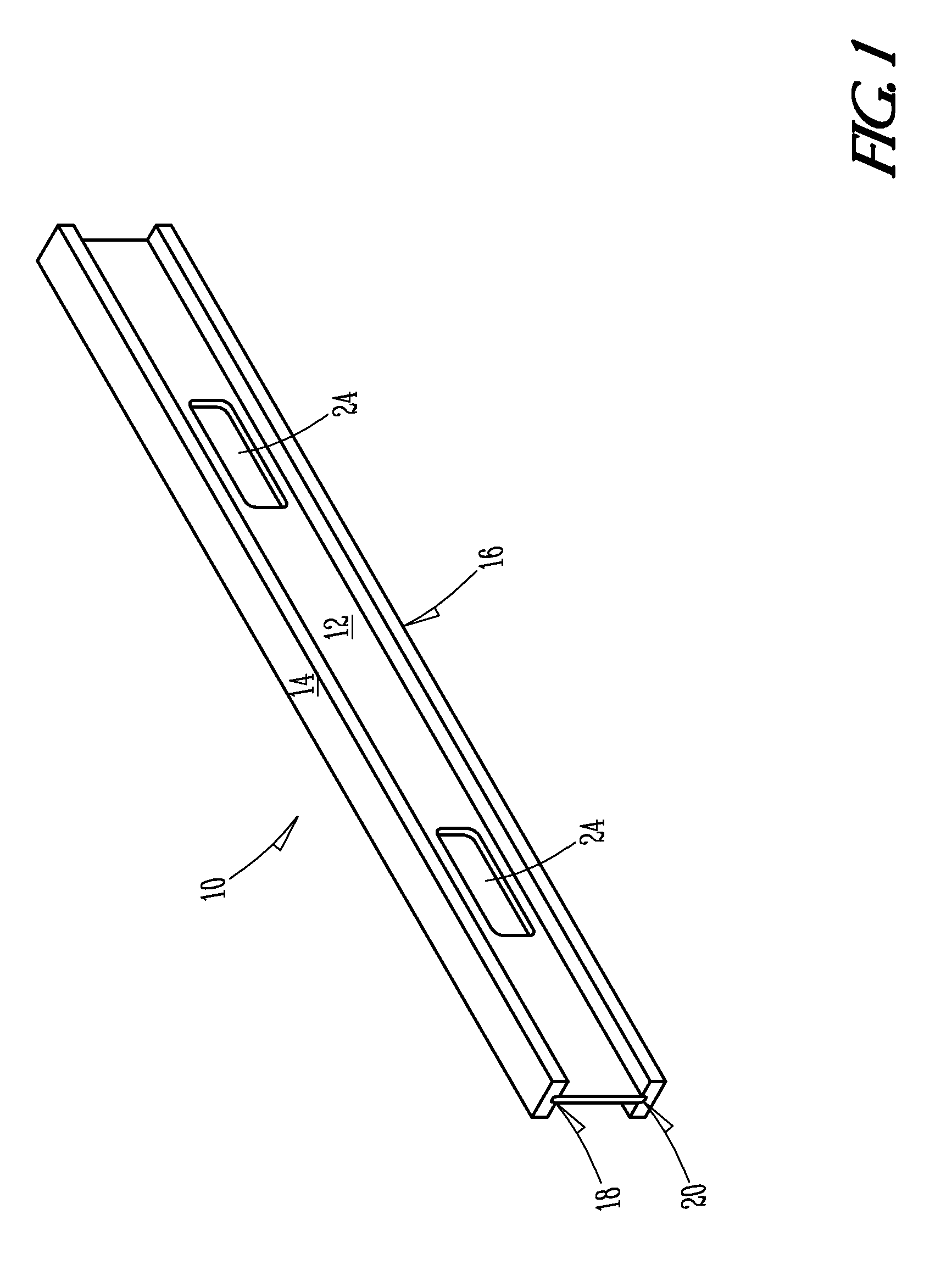

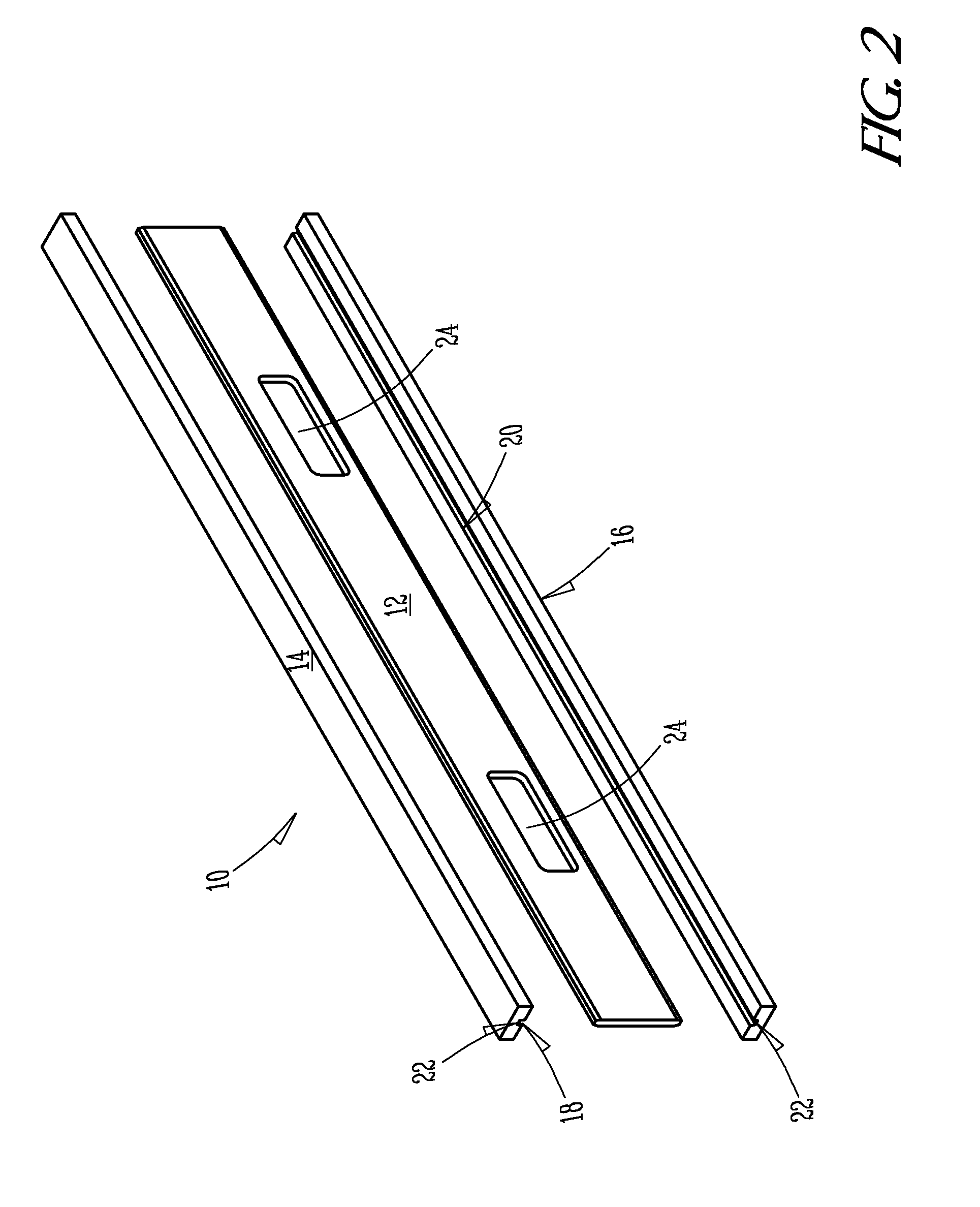

[0024]In FIGS. 1 and 2, a stud 10 is depicted. Stud 10 comprises a web 12 and flanges 14, 16, such that when viewed from one end or in cross-section, stud 10 resembles an “I”. Thus, stud 10 may interchangeably be referred to herein as an i-stud. Each of web 12 and flanges 14, 16 are manufactured using oriented strand board (OSB). Flanges 14, 16 are of unitary, one-piece construction and are not laminated. Each flange 14, 16 has a longitudinal channel or groove 18, 20 that is roughly centrally located about a face of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com