High Efficiency Furnace/Air Handler Blower Housing with a Side Wall Having an Exponentially Increasing Expansion Angle

a technology of high efficiency furnace and side wall, which is applied in the direction of machines/engines, liquid fuel engines, lighting and heating apparatus, etc., can solve the problems of large amount of pressure and air flow, and achieve the effect of overcoming efficiency problems, less pressure drop, and efficient turning of the velocity head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

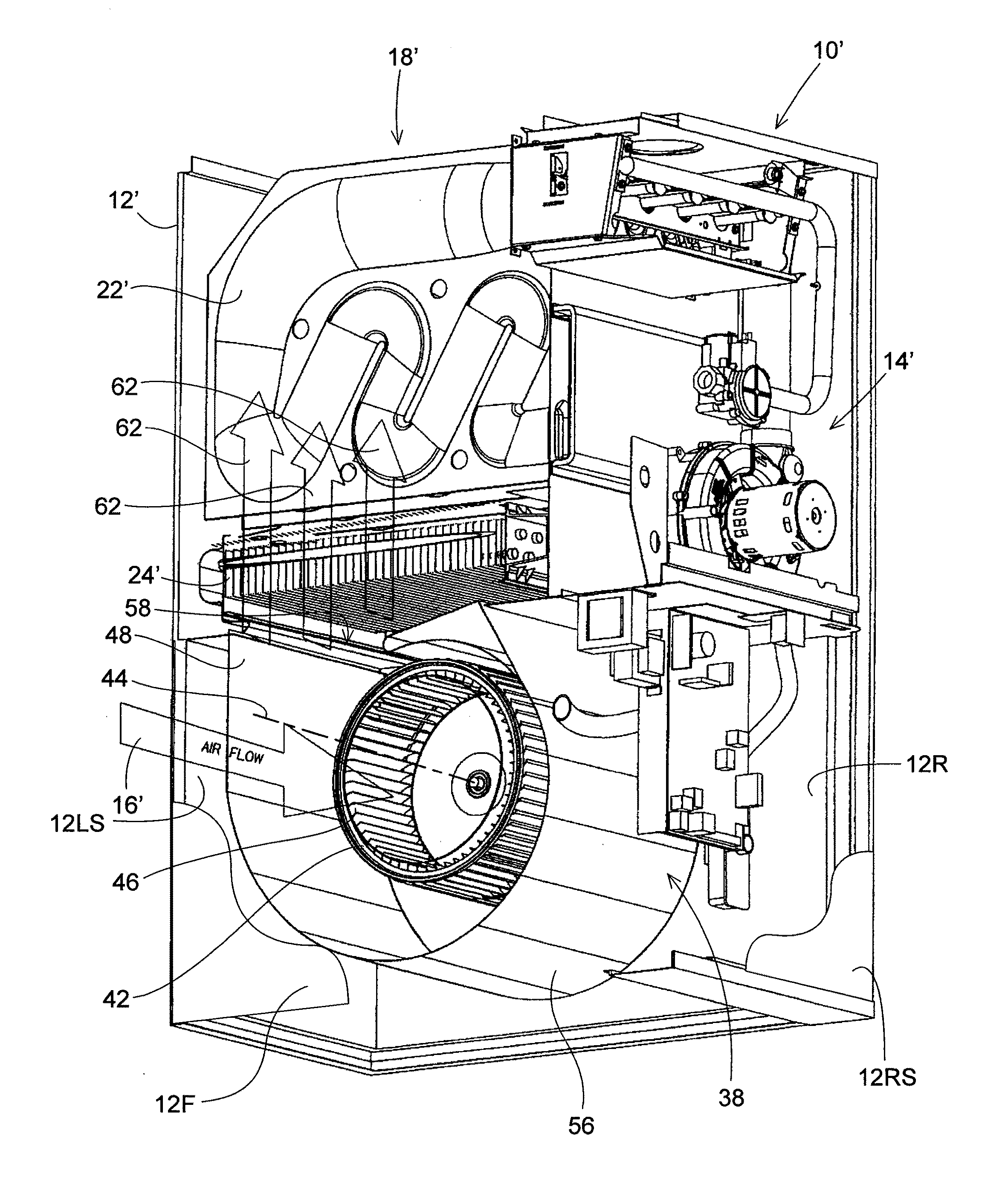

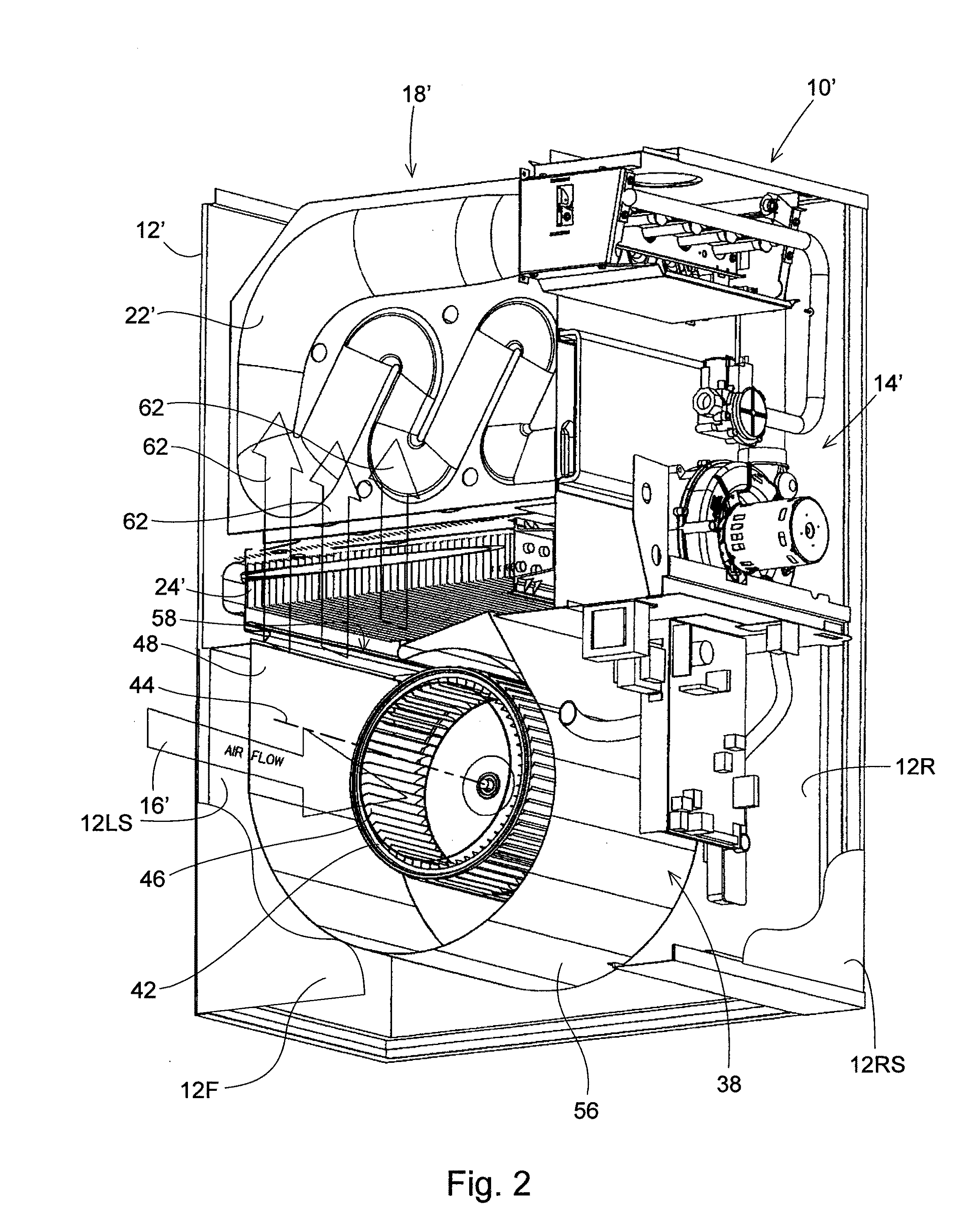

[0028]FIG. 2 is a perspective, cut away view of the high efficiency furnace of the invention that employs the blower housing of the invention having an enlarged air outlet opening and an exponentially increasing expansion angle. The furnace of the invention is primarily constructed in the same manner as known high efficiency furnaces. The difference in the furnace of the invention is in the unique design of the blower housing of the furnace. This unique design of the blower housing provides a superior distribution of air flow through the secondary and primary heat exchangers of the furnace, and thereby reduces the horsepower required by the distribution blower motor enabling an increase in the efficiency of the high efficiency furnace. Because much of the construction of the furnace shown in FIG. 2 is the same as that of FIG. 1, the same component parts of the furnace of FIG. 2 will be described only generally and are identified by the same reference numbers used in identifying the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com