Magnet assembly

a technology of electromagnets and magnets, applied in the direction of superconducting magnets/coils, magnetic materials, using reradiation, etc., can solve the problems of mri machines being large and expensive devices, preventing the use of mri as a diagnostic tool in applications, and operators having a high degree of skill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

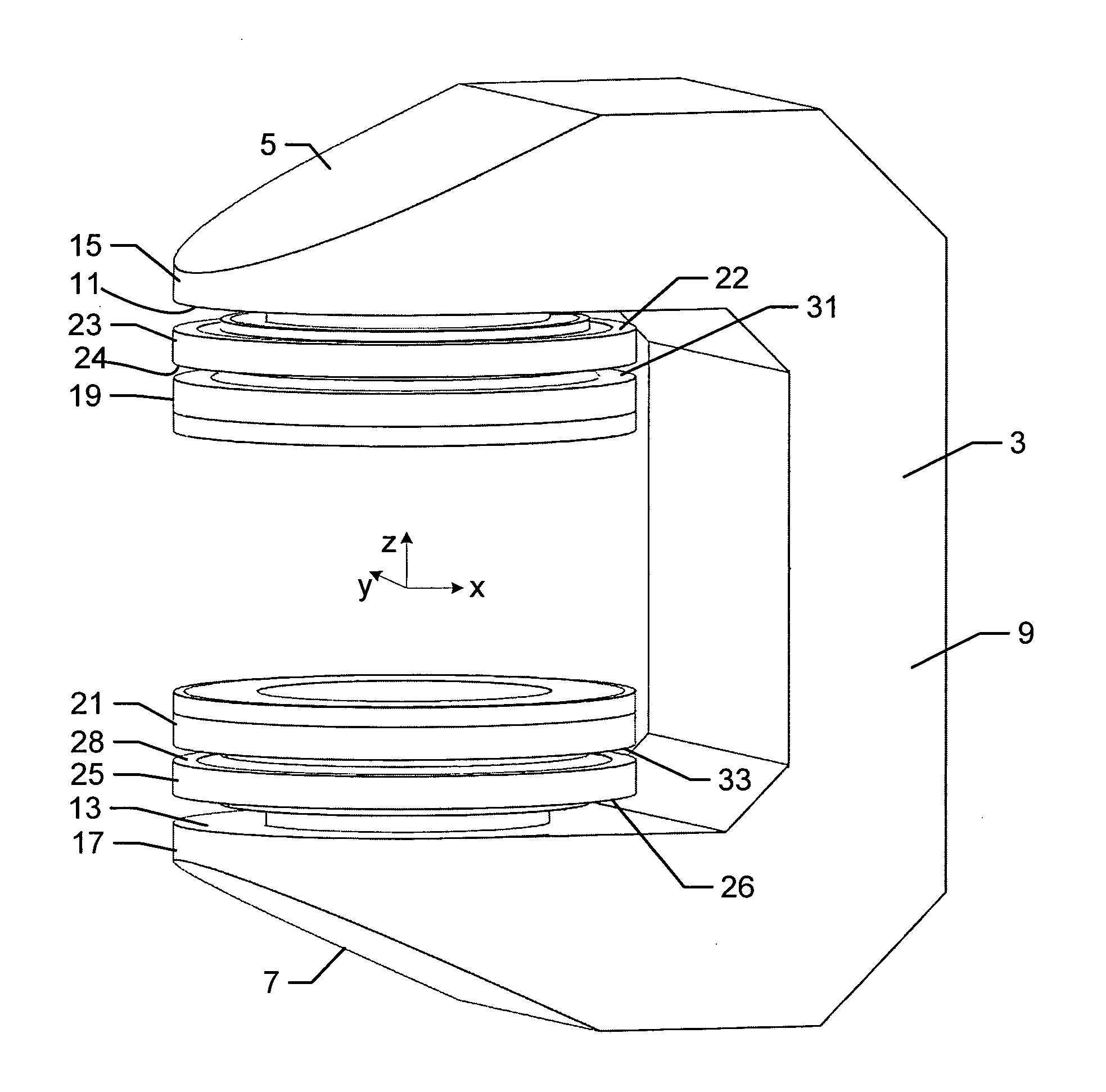

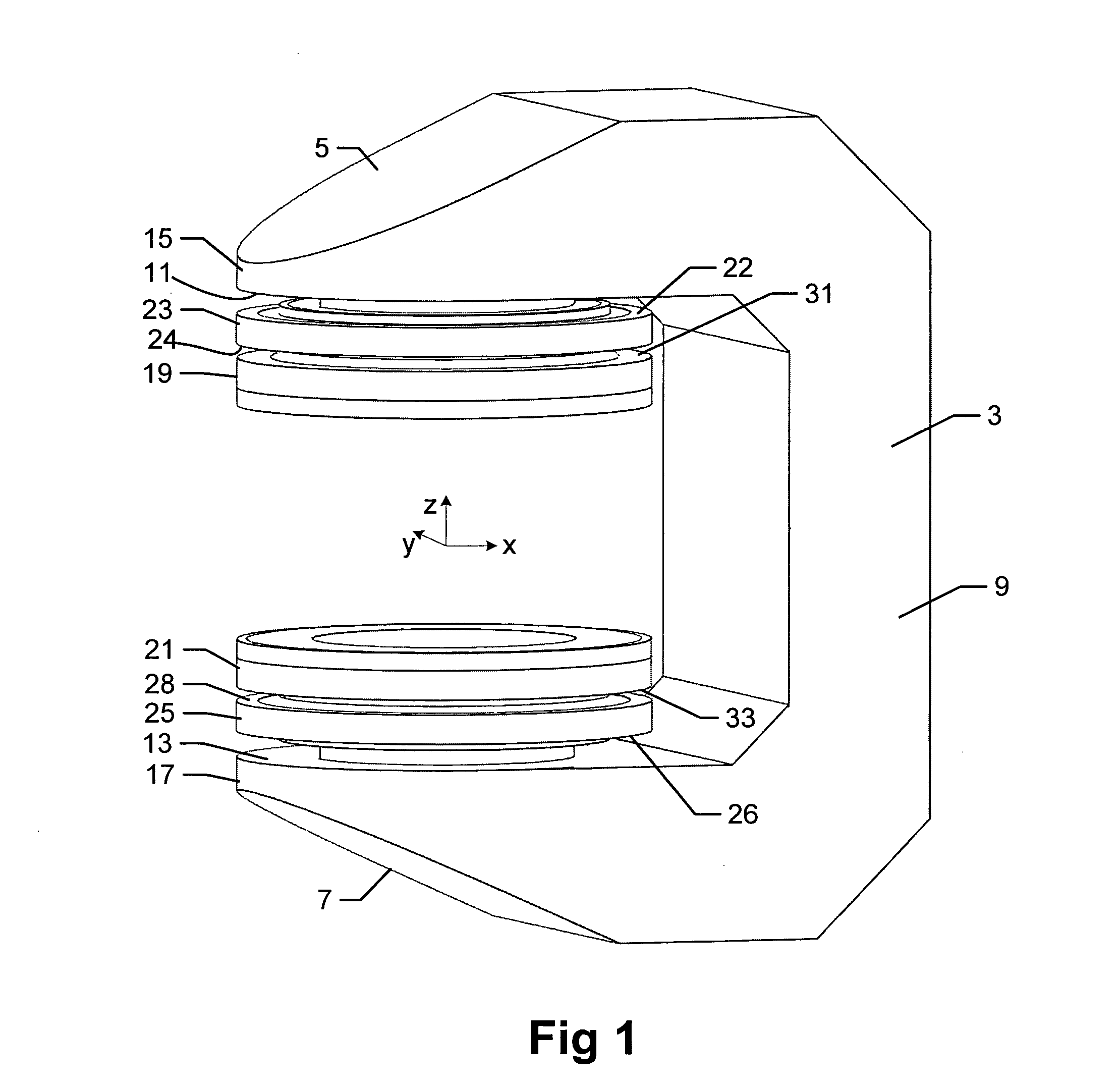

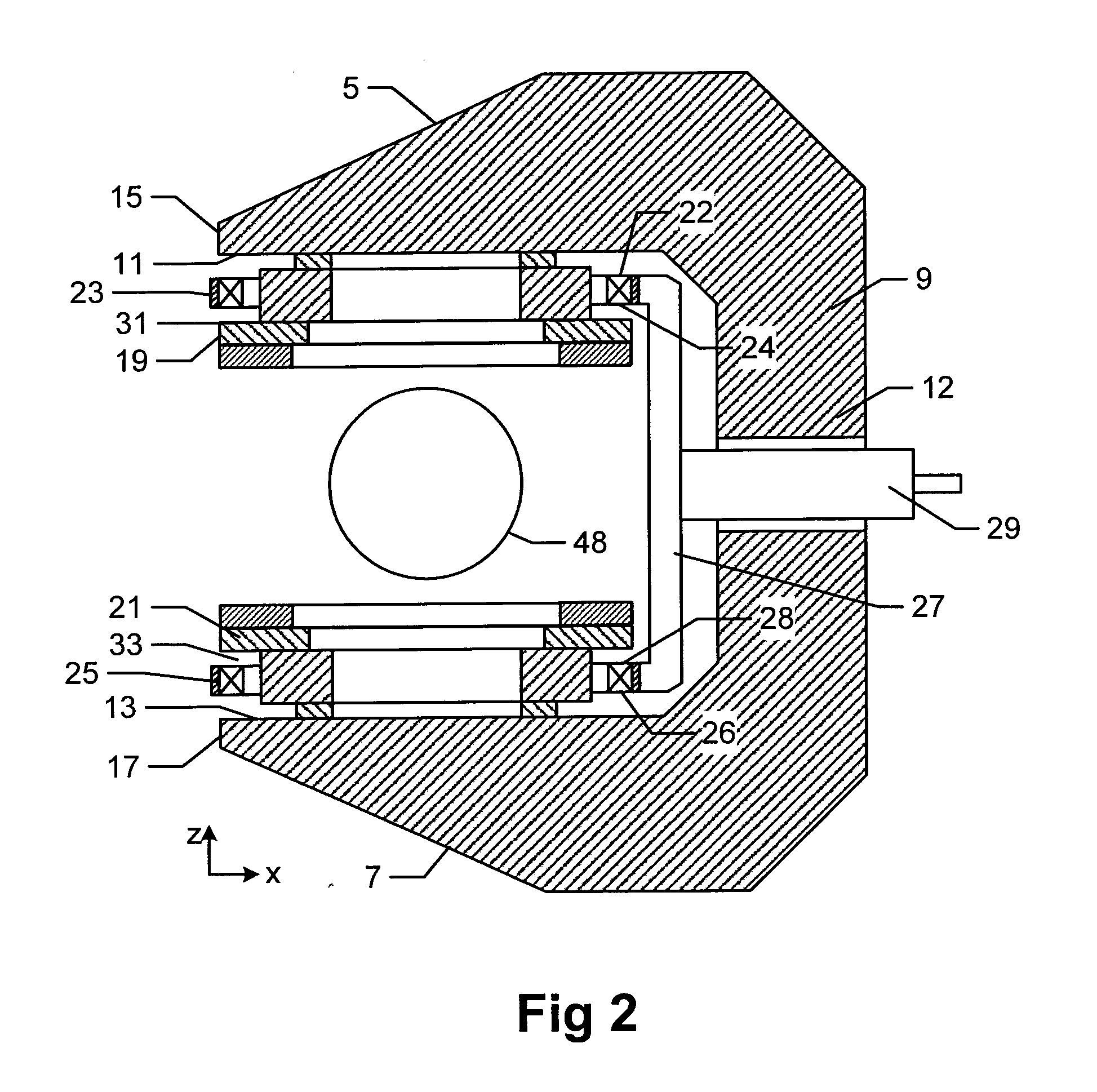

[0051]Referring now to FIG. 1, a magnet assembly 1 comprises a C-shaped steel yoke 3. The yoke itself comprises an upper arm 5, and a lower arm 7 linked by a spine 9. Mounted on the inside surfaces 11, 13 of the free ends 15, 17 of the arms 5, 7, respectively, are upper and lower pole pieces 19, 21, surrounded by respective planar annular drive coils 23, 25. In use, the coils drive magnetic flux around the yoke to produce a substantially uniform magnetic field in the central region between the poles.

[0052]The drive coil 23 has a first side 22 facing the upper yoke arm 5 and a second side 24 facing the other coil 25. Similarly, the drive coil 25 has a first side 26 facing the lower yoke arm 7 and a second side 28 facing the other coil 23.

[0053]Referring to FIGS. 2 and 3, the pair of drive coils 23, 25 carry equal currents current i in the same sense and in series with one another. The coil formers are joined by mechanical supporting member 27 to one side of the coil in the +x directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com