Method of applying zinc-phosphate conversion crystal coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

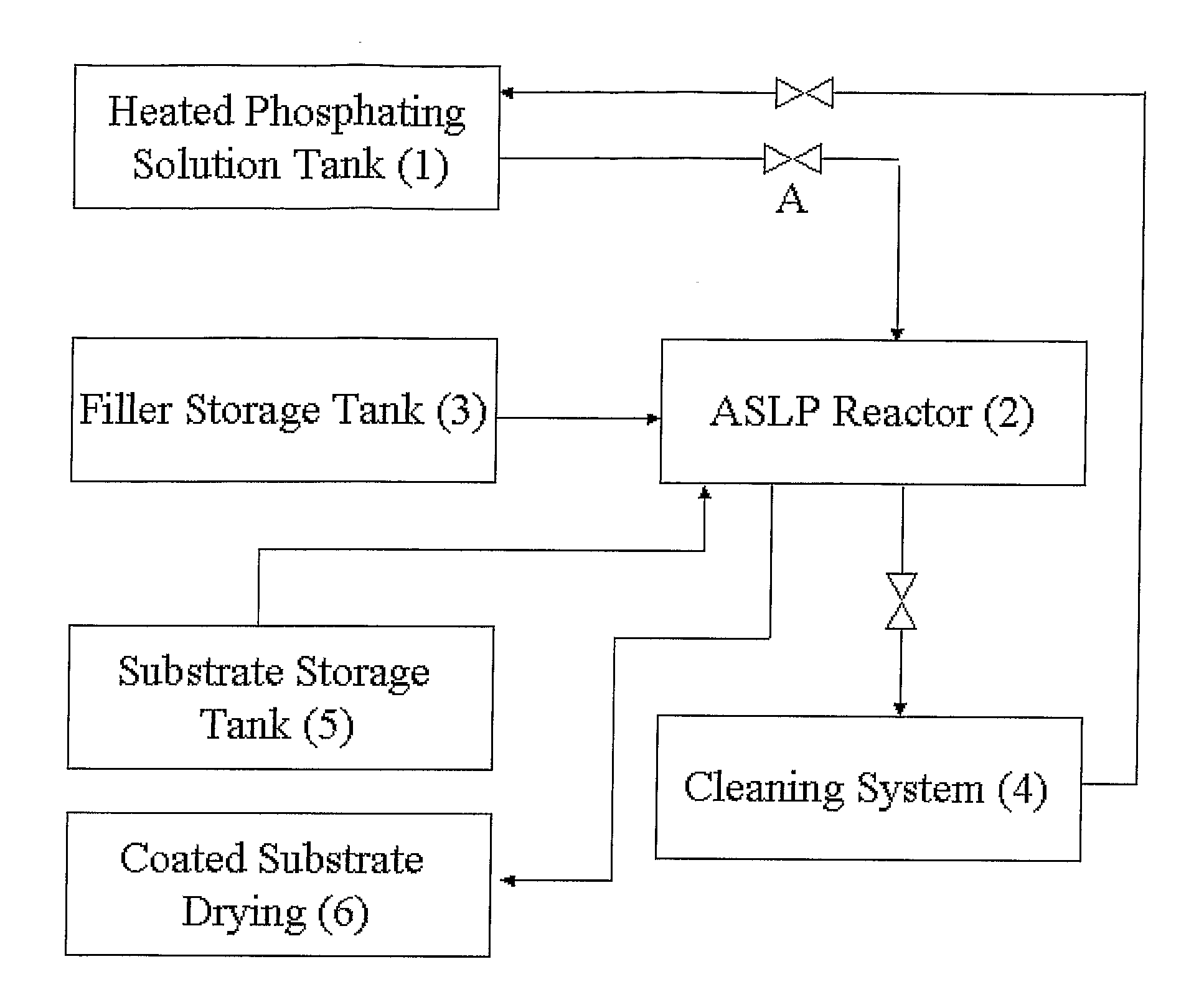

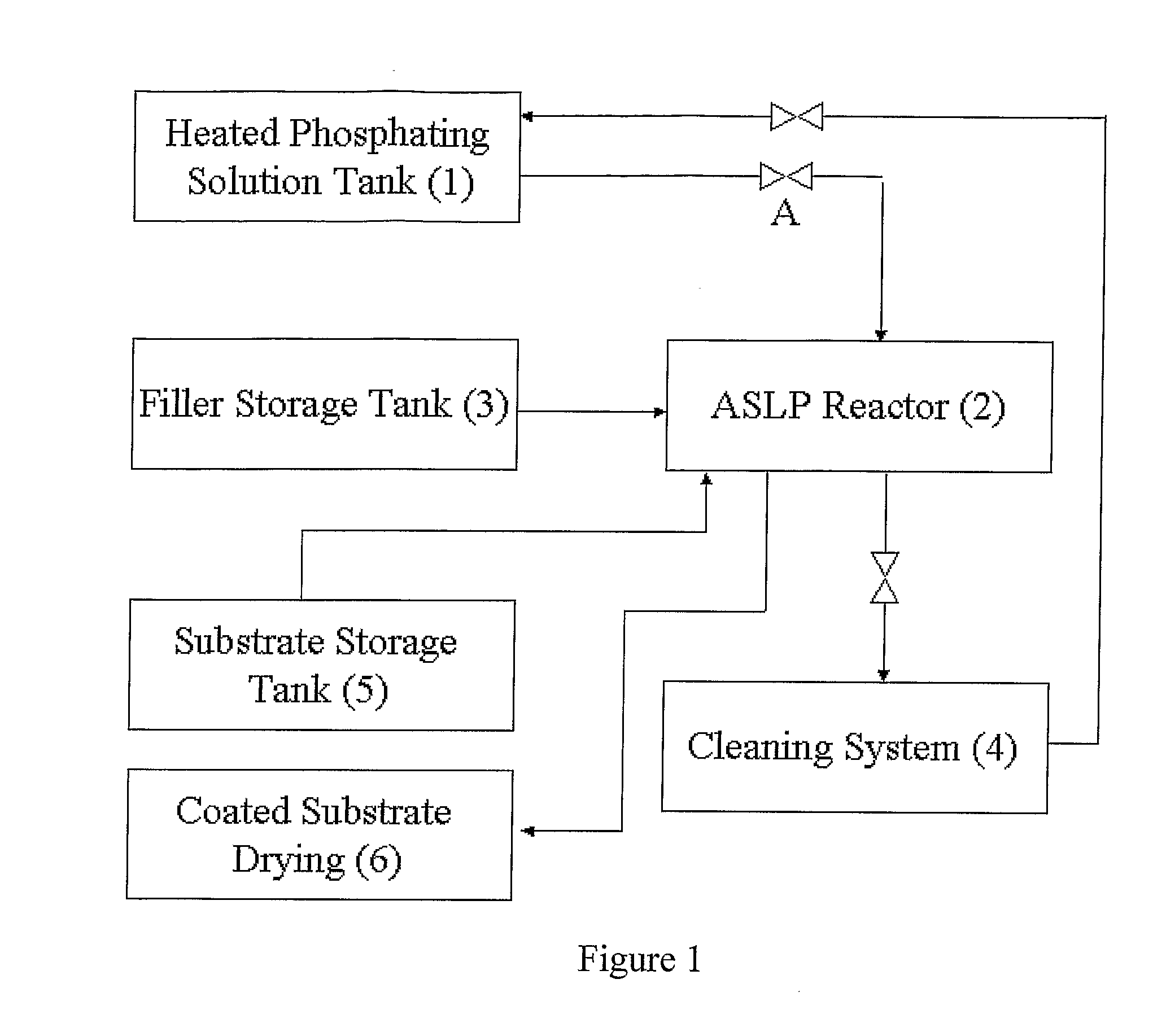

Image

Examples

experiment # 1

Experiment #1:

[0100]1. 300 ml of solution, prepared as described above, was added to a plastic beaker, having a volume of 0.5 liter.[0101]2. The quantity of metal for phosphating was 100 g.

experiment # 2

Experiment #2:

[0102]1. 700 g of porcelain chips, having triple-edged prism shape, with sides 3*3*4 mm and height 4 mm, was added to a plastic drum.[0103]2. 300 ml. of solution was added to the drum, covered with a lid, and was rotated at a rotation speed of 2 rpm, in a horizontal position during 5 minutes.[0104]3. The lid was then removed and solution fully removed, except the solution absorbed on the filler particle surfaces.[0105]4. The results of weighting show that in the drum, about 28 ml of phosphating solution was absorbed by chips and drum' sides.[0106]5. 300 g of metal for phosphating, including three control samples, were added to the drum.[0107]6. The drum was closed and revolved with rate 0.3 rpm during 10 minutes.

experiment # 3

Experiment #3: Repeated Experiment #2 with the difference being that the rate of revolution during phosphating process was 2 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com