Method of making reinforced flexible hose with leakage indicator

a flexible, reinforced technology, applied in the direction of pipe couplings, couplings, sport apparatus, etc., can solve the problems of hose failure, achieve the effect of improving the insulative properties of the hose, reducing the likelihood of peeling and sustain damage during bending, and being easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

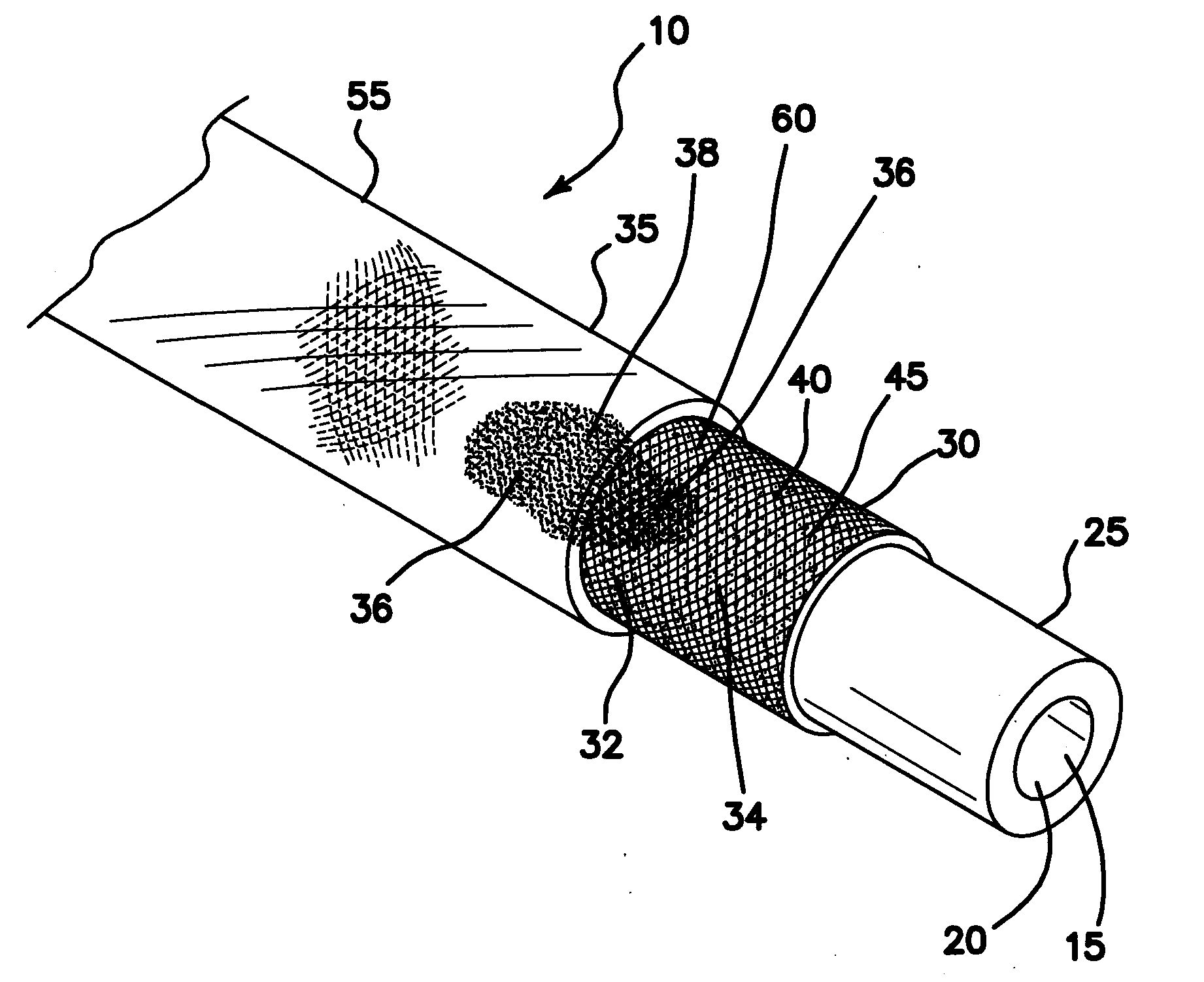

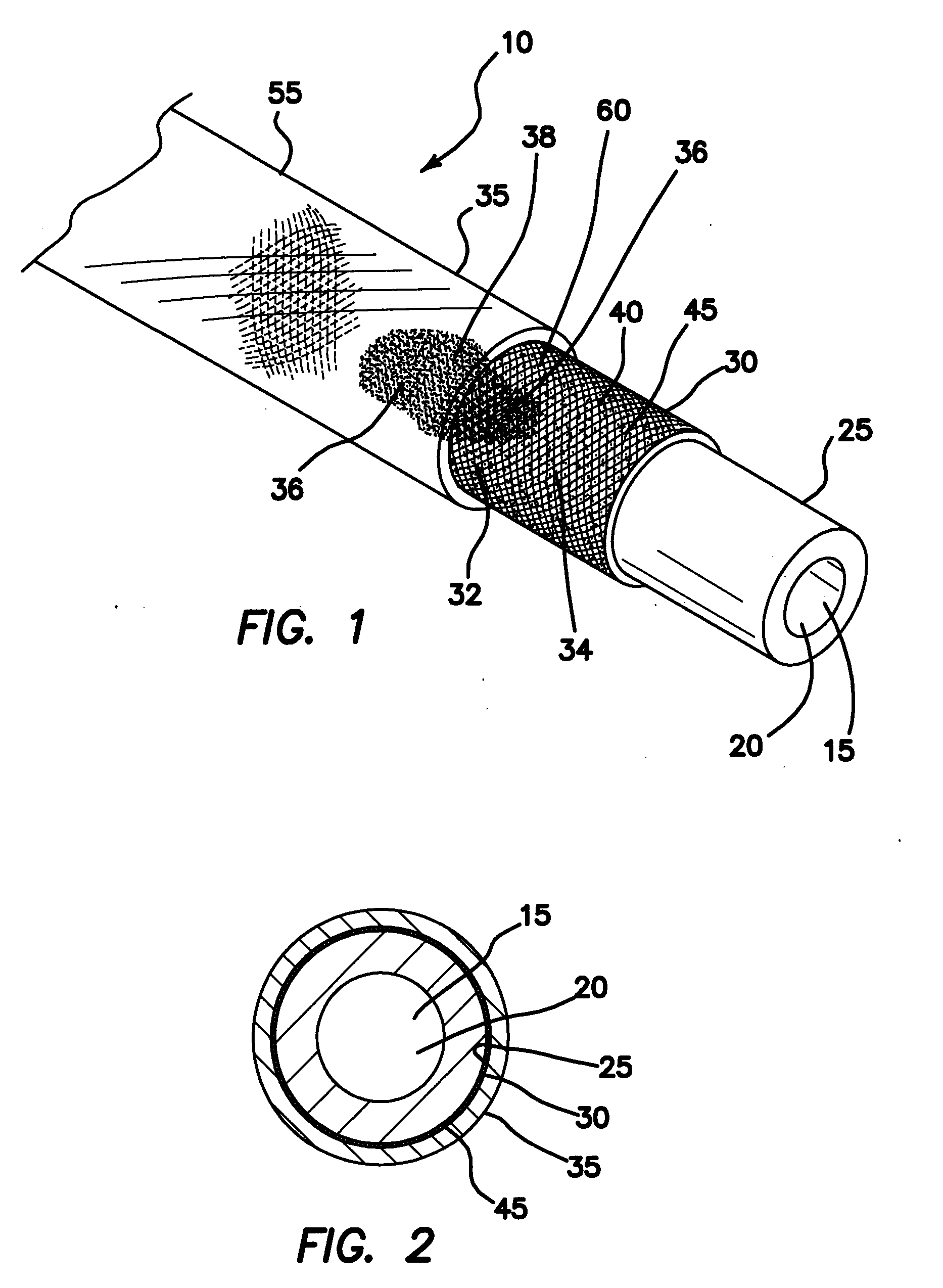

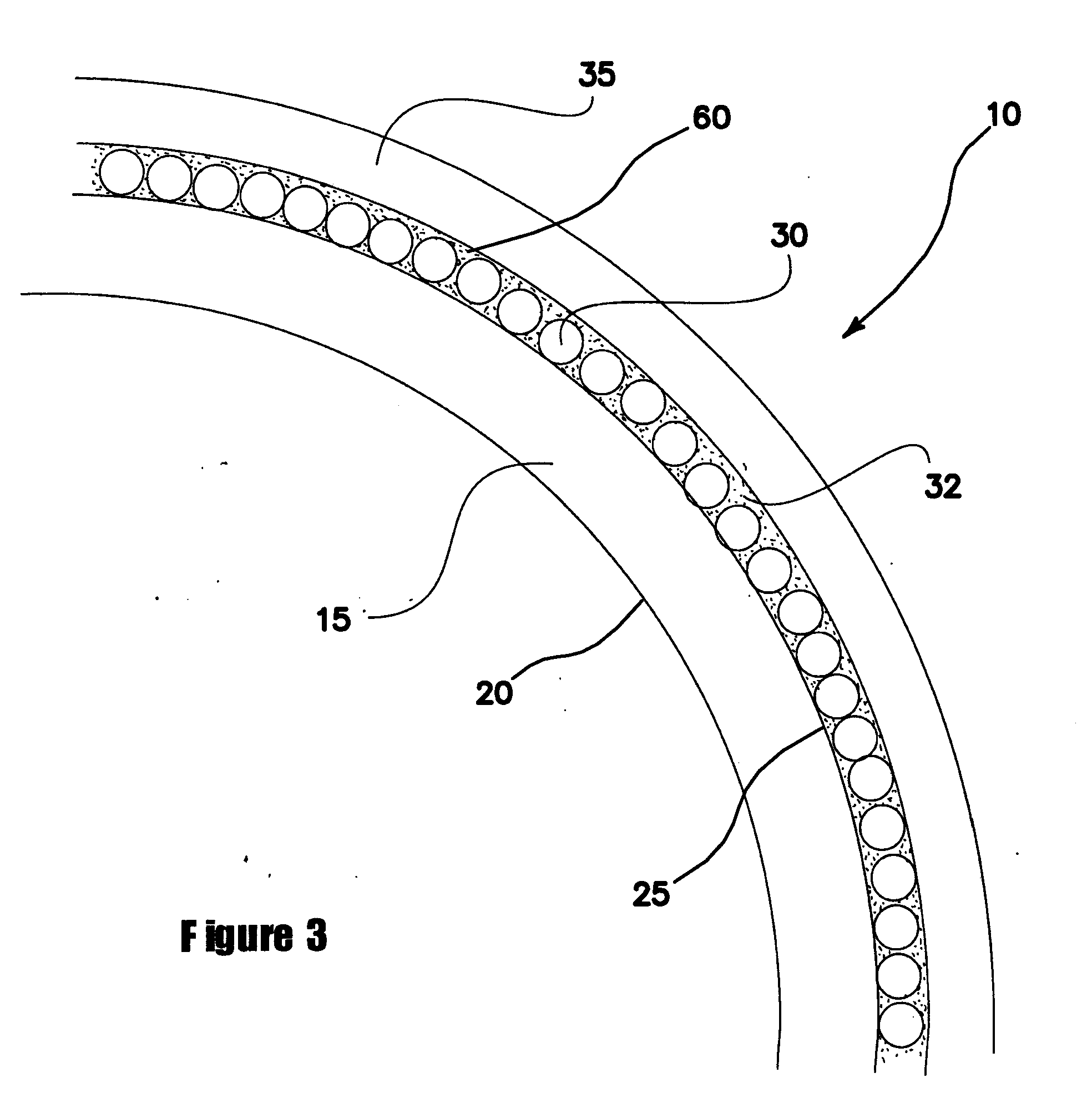

[0044]Referring to FIGS. 1, 2 and 3, 3A, 4 and 4A, a reinforced flexible hose 10 is provided. The hose 10 has an interior tube 15 for conducting a fluid. The tube 15 has an inner bore 20 and an outer surface 25. At least one layer of stainless steel threads 30 are braided about the outer surface 25 and a transparent flexible polymeric covering 35 is located over the stainless steel threads 30. The flexible polymeric covering 35 is not in intimate contact with the circumference of every thread 30. The flexible polymeric covering 35 only contacts the threads 30 tangentially. Thus pockets of air 60 are trapped between the covering 35 and the braid 30 thereby protecting the braid 30 from abrasion and corrosion and improving the insulative properties of the hose 10. A moisture sensitive compound 32 is provided. The compound 32 changes from an initial color 34 to a second color 36 upon contact with moisture 38. The compound 32 is dispersed in the pockets of air 60 trapped between the thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| transparent flexible | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com