Pre-conditioned foam pad

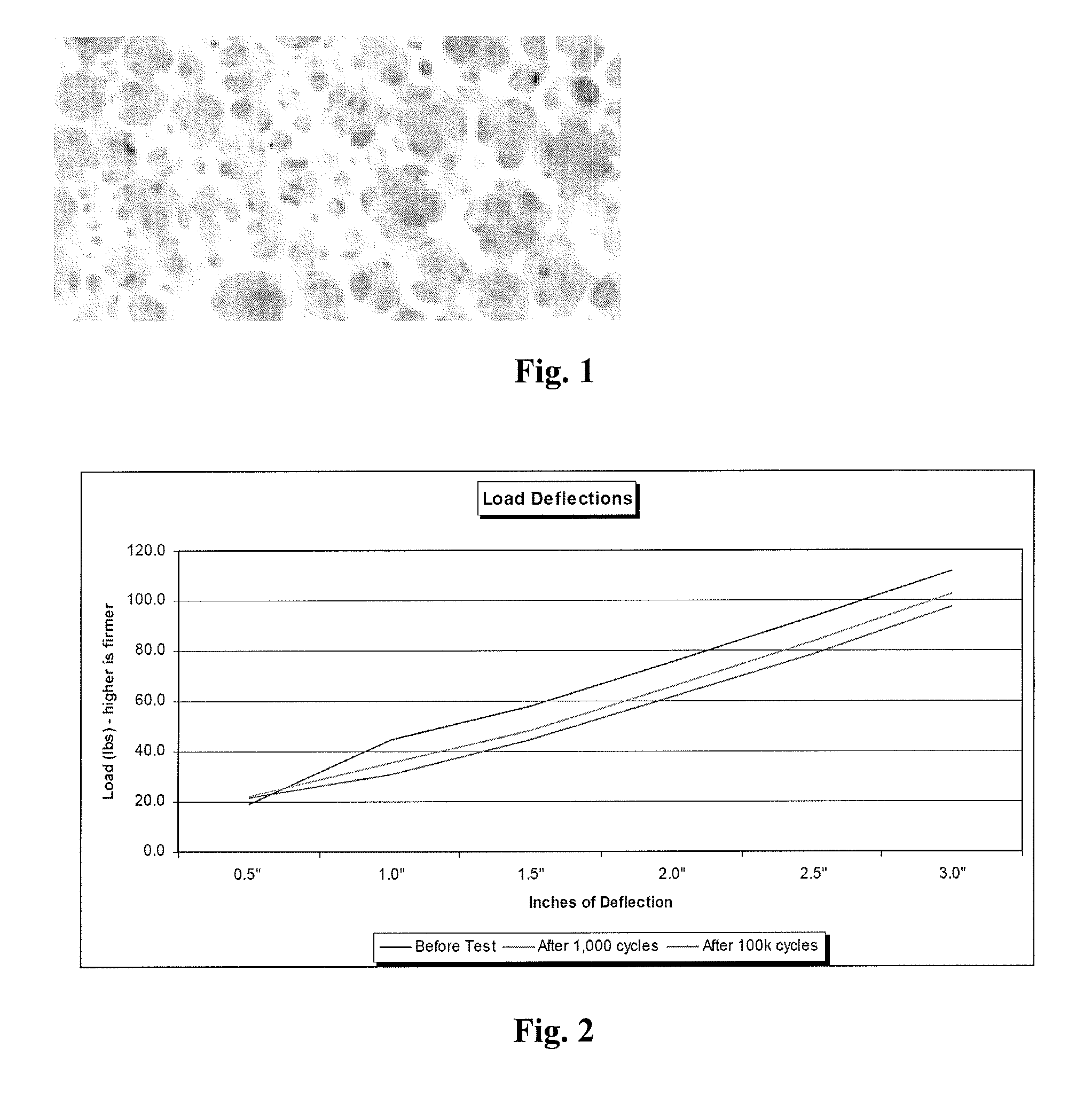

a foam pad and preconditioning technology, applied in the field of cushioning articles, can solve the problems of broken or ruptured closed cell windows, and limited air flow through the foam, and achieve the effect of accelerating the aging of the unaged mattress assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

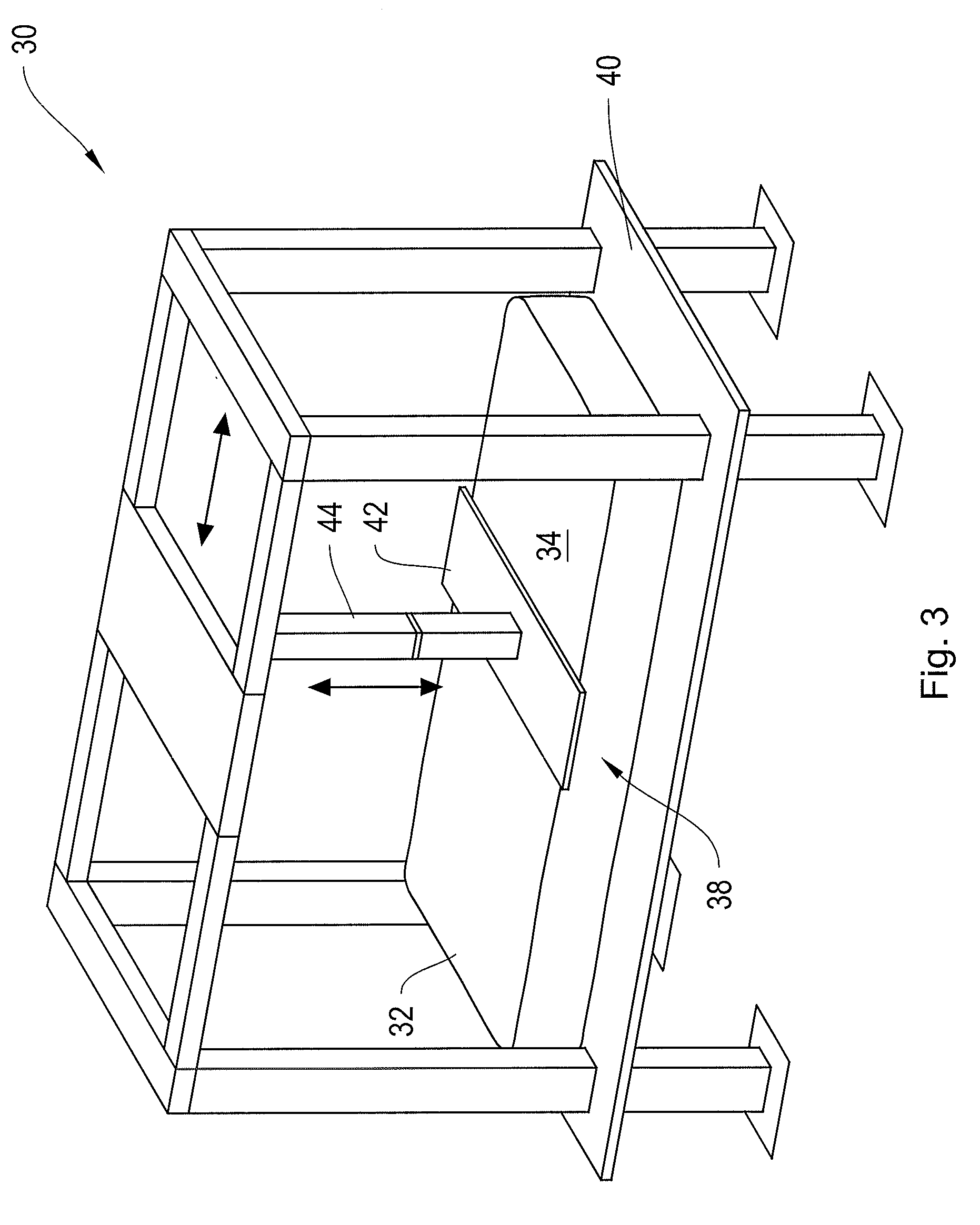

[0038]The systems and methods described herein include, among other things, systems and methods for processing and finishing a foam material for use in a mattress to provide a mattress foam material that has more consistent hardness over time and area. Although the systems and methods described herein are described with reference to use with a mattress or sleeping surface, it will be understood by those of skill in the art that the foam processing techniques and systems described herein may be applied in other applications including other furniture related applications for sofas, chairs, love seats, boat seats, and other applications.

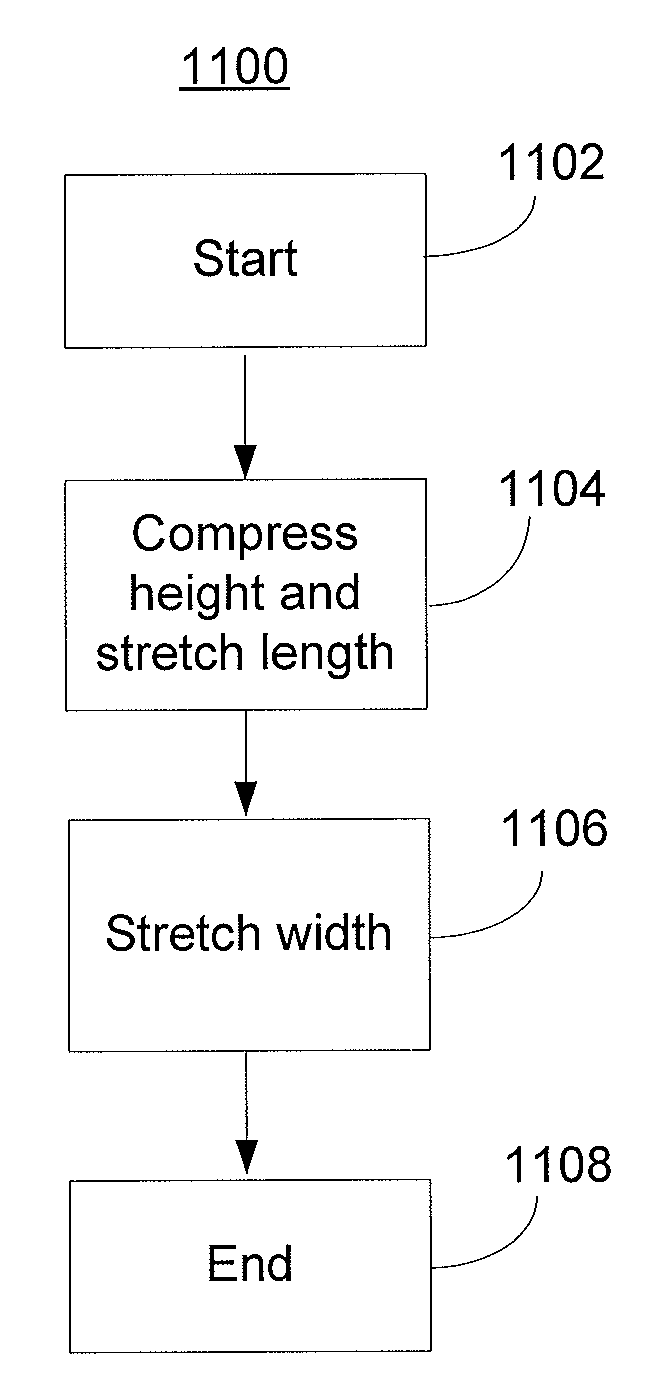

[0039]Turning to FIG. 1, there is depicted a photomicrograph of an open-cell foam material. Foam material may include polyurethane foam manufactured from synthetic or natural raw materials or latex foam material. Polyurethane foam is typically made by introducing tiny expandable gas bubbles into a reacting mixture of a polyol, a polyisocyanate and other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| mechanical property | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com