Method and system for filling a gas cylinder

a gas cylinder and gas filling technology, applied in the direction of liquid handling, container discharging methods, packaged goods types, etc., can solve the problems of overpressure disc in the cylinder, and cylinders that cannot be filled properly, so as to reduce the number of operator errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

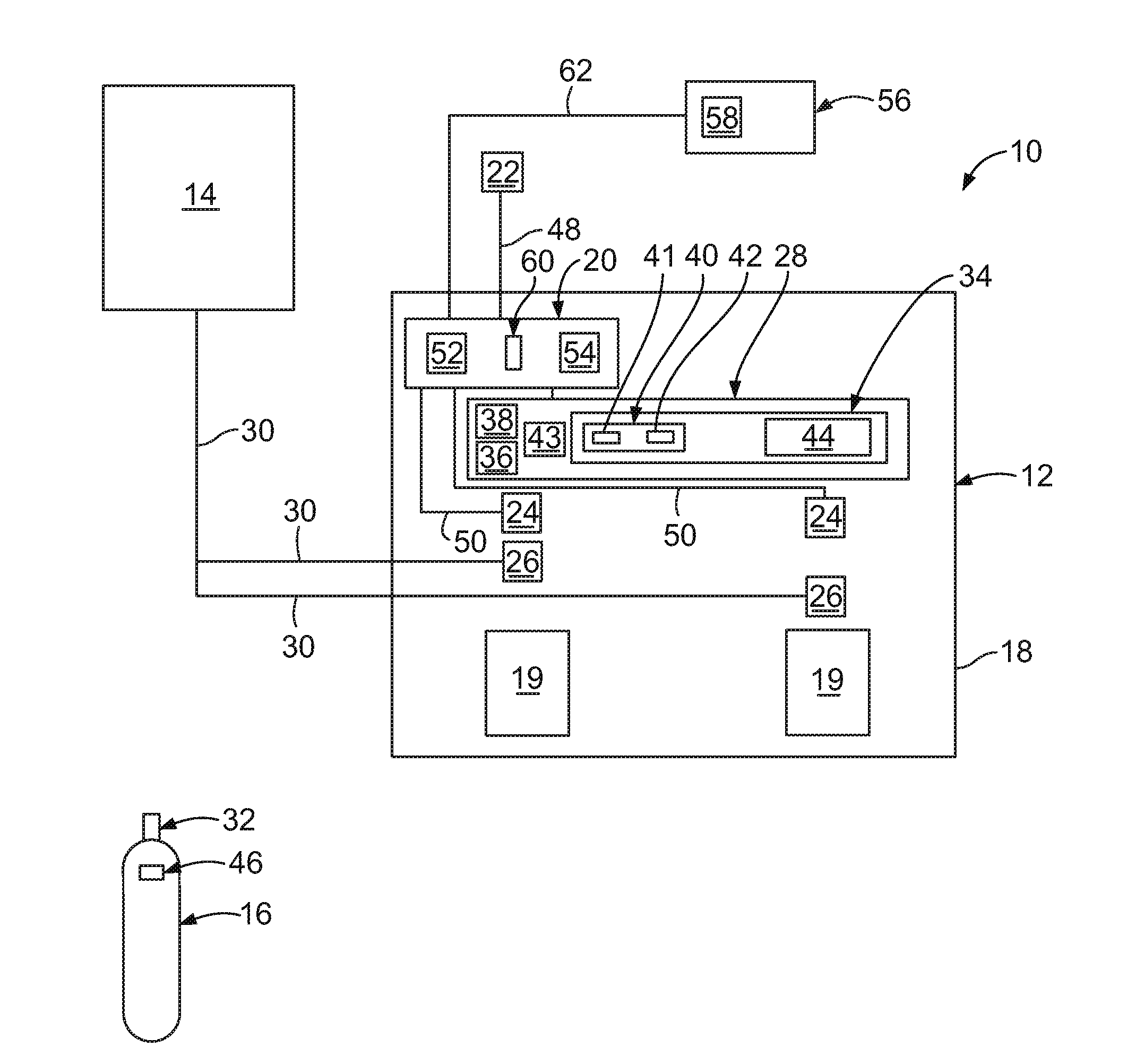

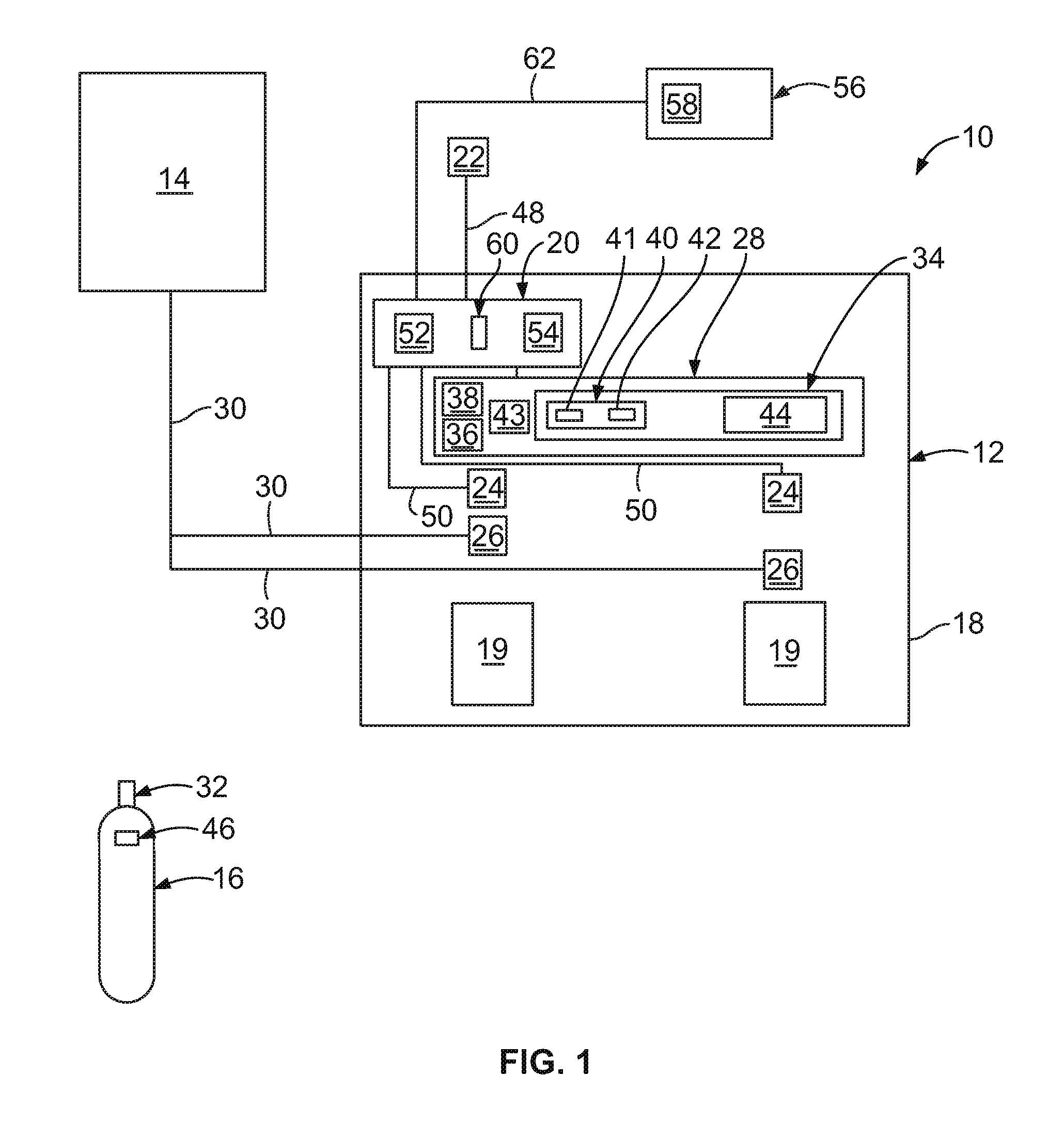

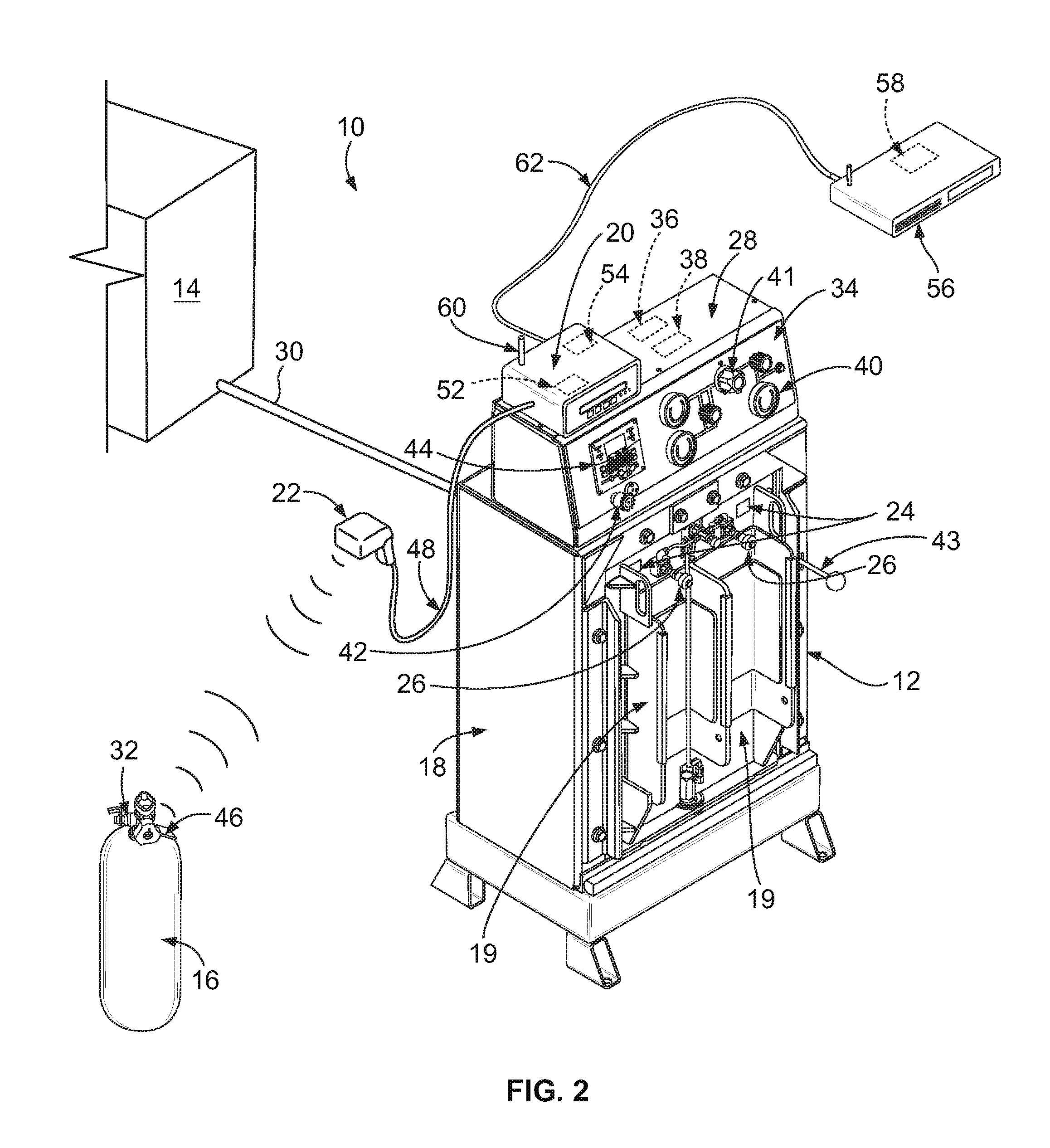

[0013]FIG. 1 is a block diagram of an exemplary embodiment of a gas cylinder filling system 10. FIG. 2 is a perspective view of the gas cylinder filling system 10. The gas cylinder filling system 10 includes a charge station 12 and a supply of gas 14. As will be described below, the charge station 12 is configured to fill a gas cylinder 16 with a gas. The gas may be any gas, such as, but not limited to, a breathing gas (such as, but not limited to, air, oxygen, nitrox, tirmix, heliox, heliair, hydreliox, hydrox, neox, and / or the like) and / or the like. The gas cylinder 16 may be any type of gas cylinder, such as, but not limited to, a gas cylinder for a self-contained breathing apparatus (SCBA), a space suit, medical equipment, a self-contained underwater breathing apparatus (SCUBA), and / or the like. Although shown as generally cylindrical in shape, in addition or alternatively to the cylindrical shape, the gas cylinder 16 may include any other shape(s).

[0014]The charge station 12 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| operating pressure | aaaaa | aaaaa |

| fill pressure | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com