Method for tuning a deposition rate during an atomic layer deposition process

a technology of atomic layer and deposition rate, which is applied in the direction of chemical vapor deposition coating, coating, special surfaces, etc., can solve the problems of pvd process reaching a limit at this size and aspect ratio, many challenges to process control, lack of stability of deposition rate and minumium control, etc., and achieve the effect of reducing the deposition rate of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

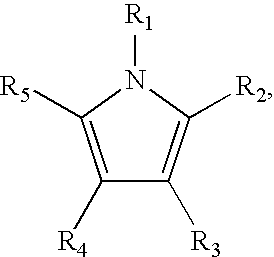

Image

Examples

Embodiment Construction

[0025]Embodiments of the invention provide methods for depositing a material on a substrate within a processing chamber during a vapor deposition process, such as an atomic layer deposition (ALD) process or a chemical vapor deposition (CVD) process. Generally, the substrate may be continuously or periodically exposed to a treatment gas containing a reagent prior to and / or during the vapor deposition process. The treatment gas may be administered into the processing chamber and the substrate is exposed to the treatment gas prior to and / or during the vapor deposition process. The deposition rate of the material being deposited may be controlled by varying the amount of treatment gas exposed to the substrate. Therefore, the deposition rate may be adjusted, such as within a range from about 0.05 Å / cycle (Å per ALD cycle) to about 1.0 Å / cycle, for example, about 0.5 Å / cycle.

[0026]In one example, the method includes exposing the substrate to the treatment gas to reduce the deposition rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Deposition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com