Breech block for a drop-down barrel weapon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

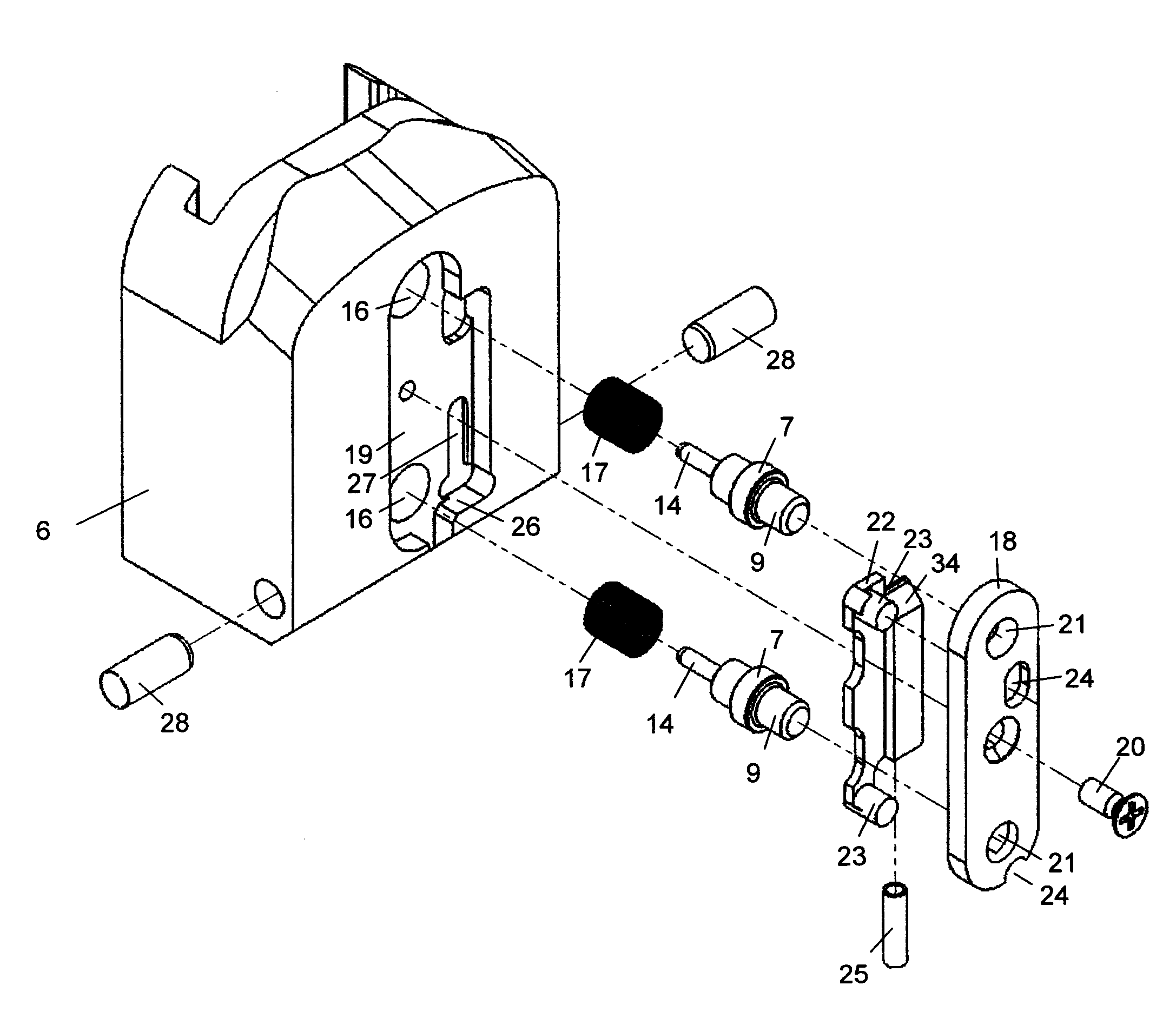

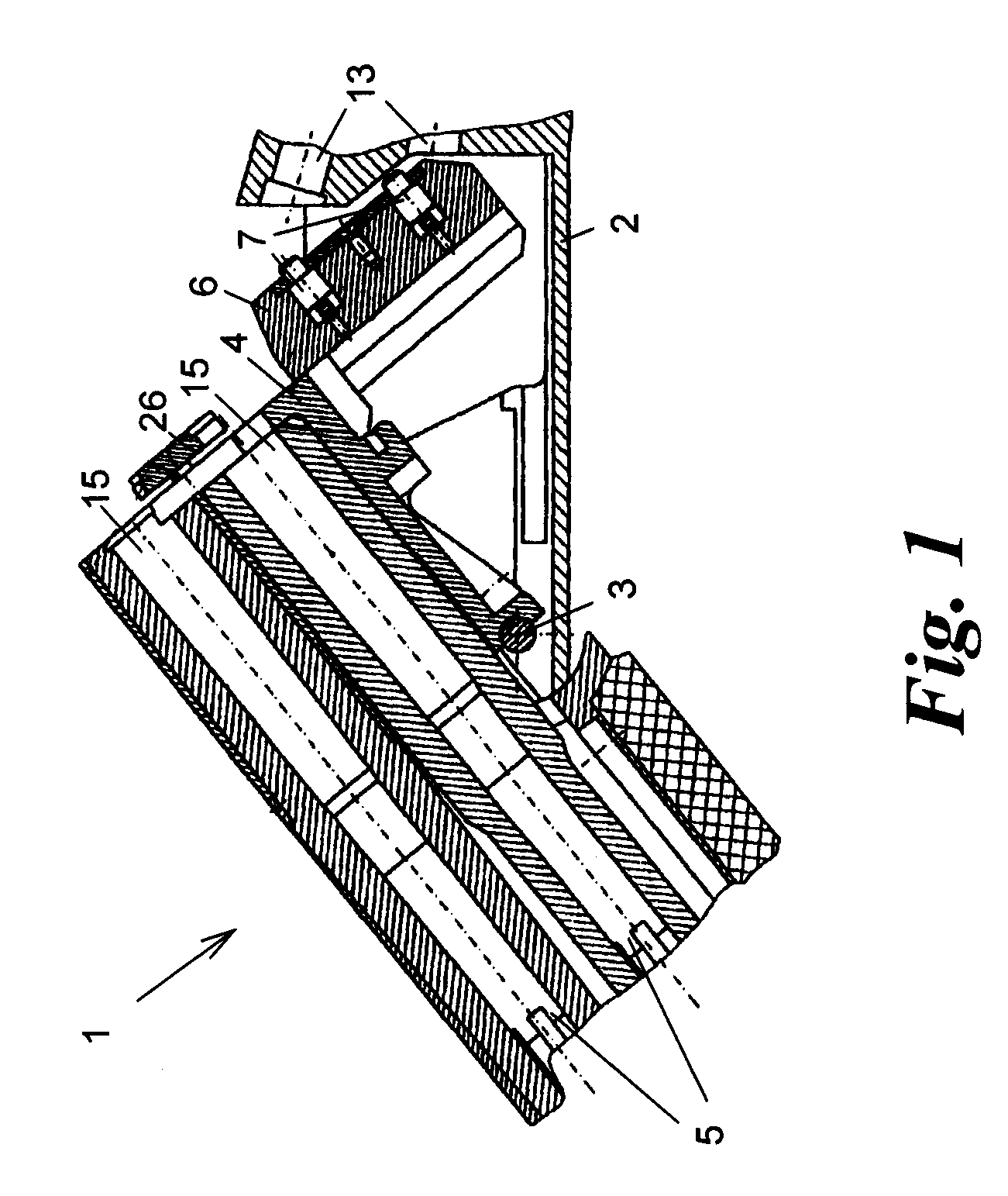

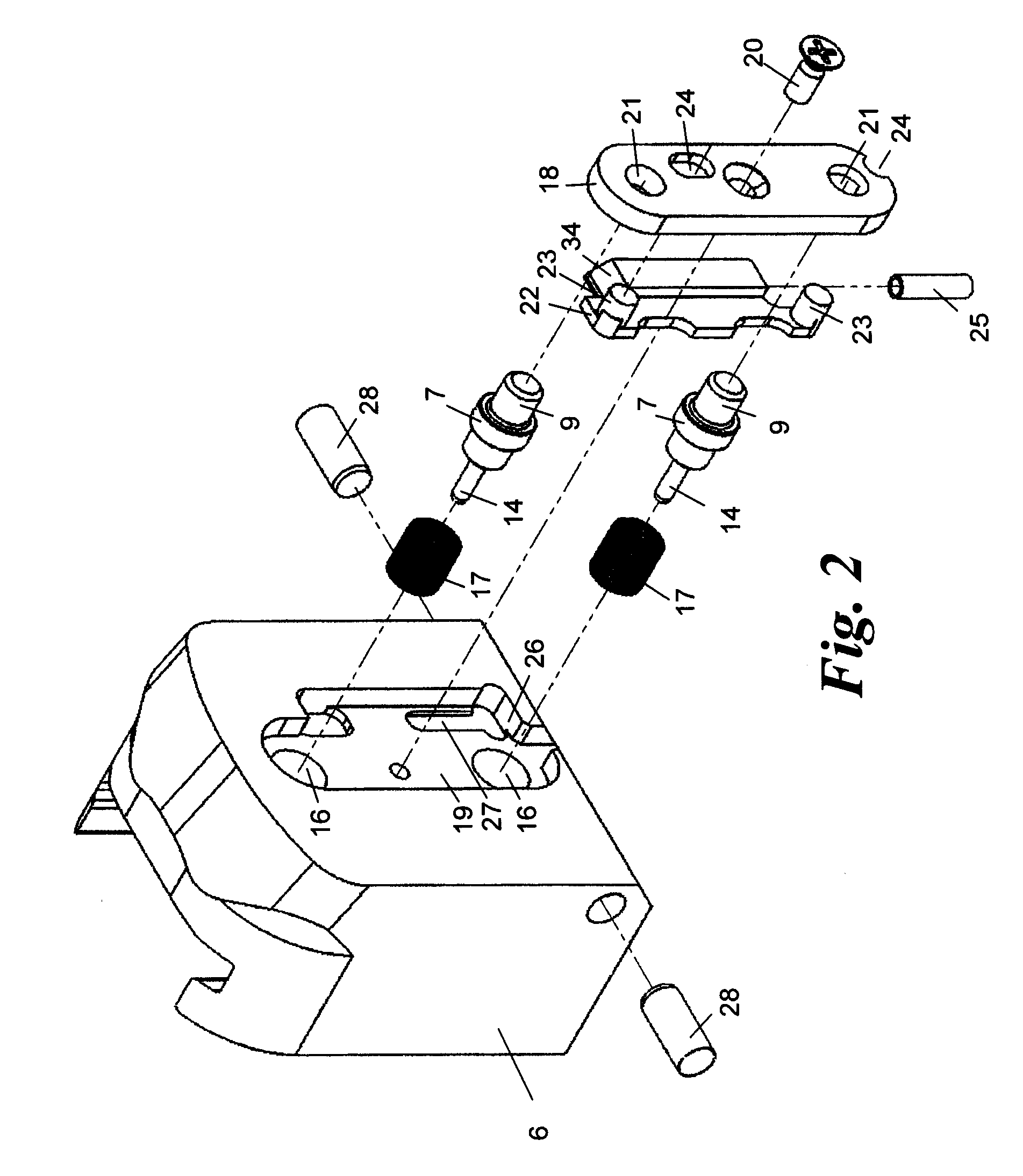

[0017]A drop-down (“tip-up”) barrel weapon 1 is shown in sections in FIG. 1, i.e. only in the region of its (here: open) block lock. The block lock comprises a link 2 and a mount 4 articulated thereto at 3 to accommodate two barrels 5 and a breech block 6, which is guided to be transversely displaceable on the mount 4, as is known in the art.

[0018]FIG. 2 shows the breech block 6 in detail. The breech block 6 contains two firing pins 7 guided displaceably in axial direction. Each firing pin 7 has an impact head 9 on its rear side for one respective firing piece 11 (FIGS. 3 and 4), which is guided in guides 13 (FIG. 1) of the link 2 and is biased for firing, as is known to the person skilled in the art. On its front side each firing pin 7 has a firing tip 14 for firing a cartridge (not shown) in the cartridge storage areas 15 of the barrels 5.

[0019]The firing pins 7 are guided in stepped holes 16 of the breech block 6 and respectively biased towards the firing pieces 11 by a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com