Take apart water craft

a watercraft and take-away technology, applied in the field of watercraft, can solve the problems of deteriorating bolt holes, high stress and failure of bolts, and time-consuming bolt assembly operation, and achieve the effect of simple moulding and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

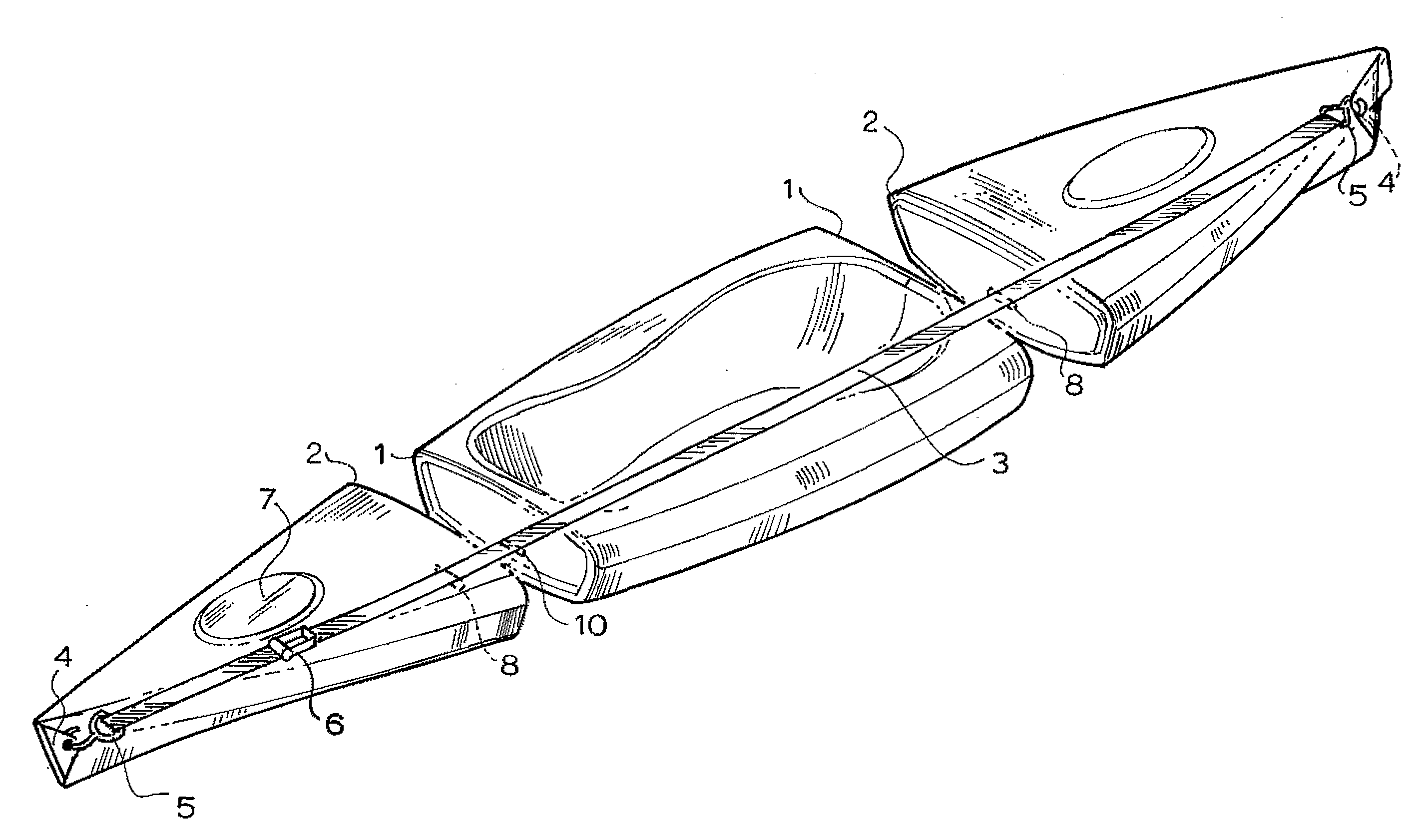

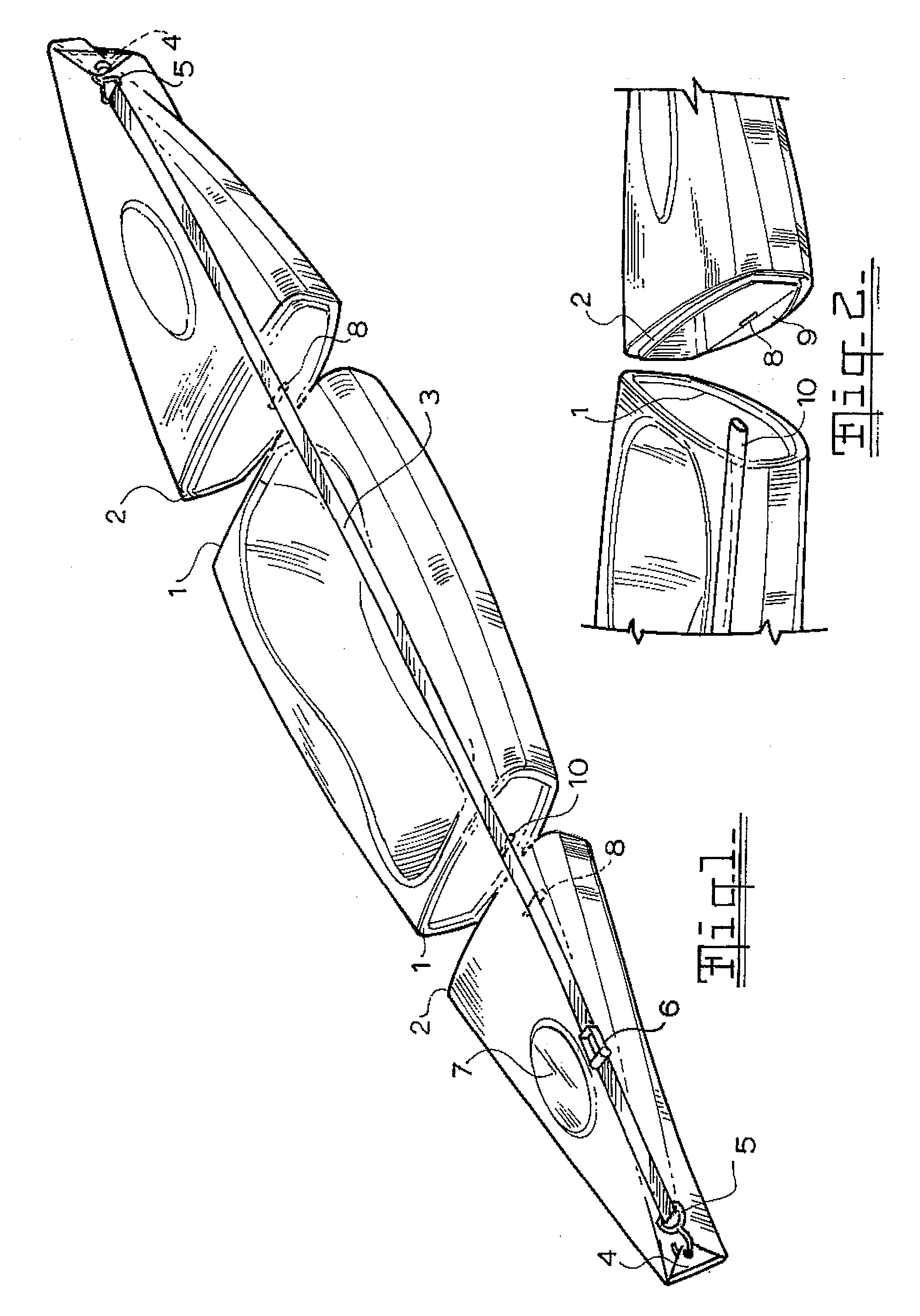

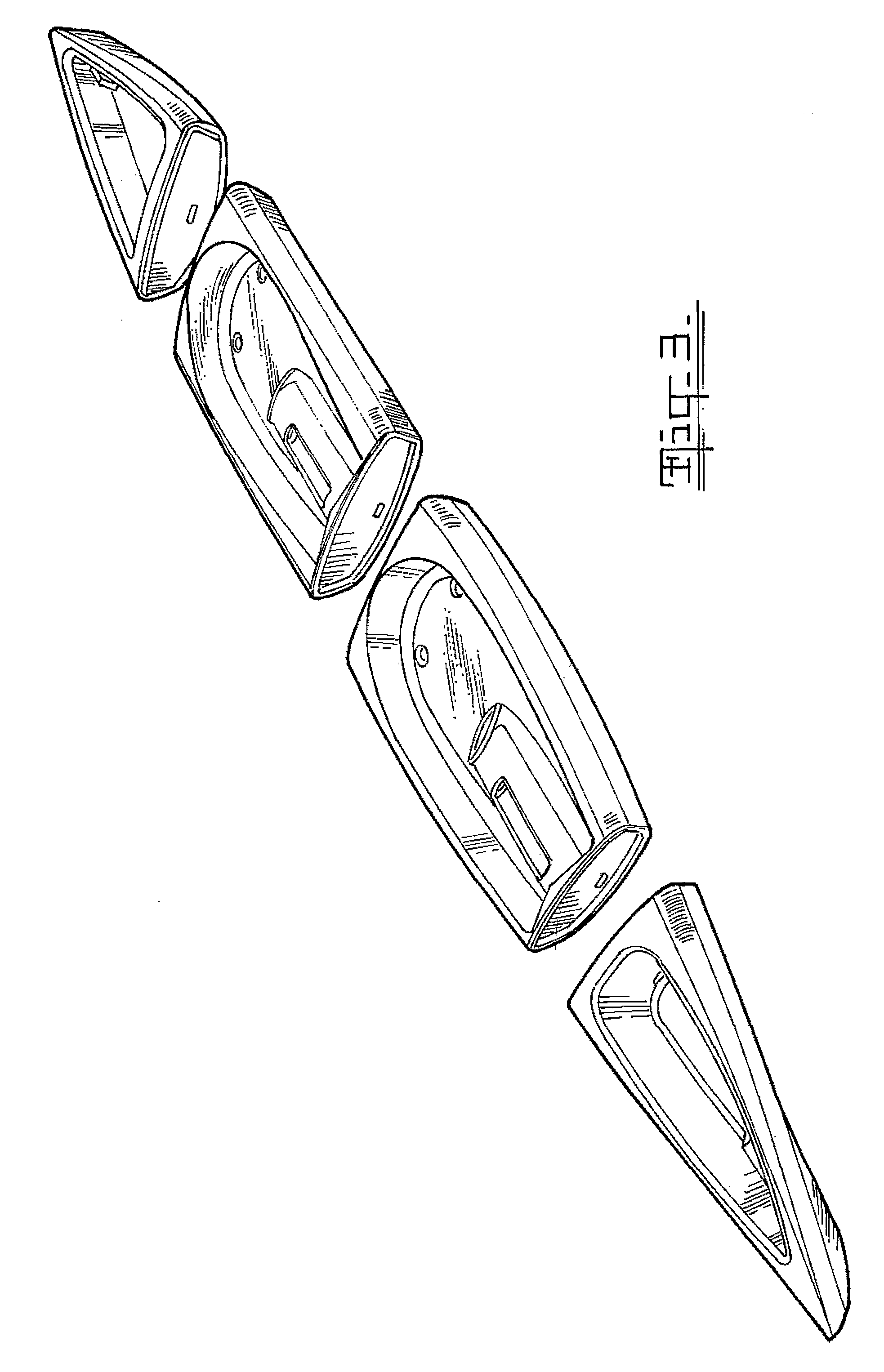

[0023]FIG. 1 shows interfacing bulkheads 1, 2 of a three section kayak. Bulkheads 1 have inward tapering ridges while opposing bulkheads 2 have outward tapering ridges. Accordingly when the sections are brought together the tapered ridges first align mating bulkheads 1, 2 which then fit securely into one another eliminating movement between bulkheads 1,2 in both vertical and lateral directions.

[0024]Tensioning strap 3 is used to draw the three sections together and to apply a compressive force which locks them in sealing engagement. Strap 3 has hooks 5 at each end which engage brackets 4 molded into the bow and stern of the kayak. Ratchet 6, accessed through hatch 7, is used to tension strap 3 so that the compressive force between the bulkheads is greater than the separating forces in the water.

[0025]Tensioning strap 3 passes through holes 8, 10 in bulkheads 1, 2 which are above the normal waterline. Accordingly even if there is some parting of bulkheads 1, 2 and water enters the sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap