Hospital bed having a locally reinforced frame

a local reinforcement and bed frame technology, applied in the field of hospital beds, can solve the problems of recurring problems such as affecting the welding seam, and the reliability of the mounting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

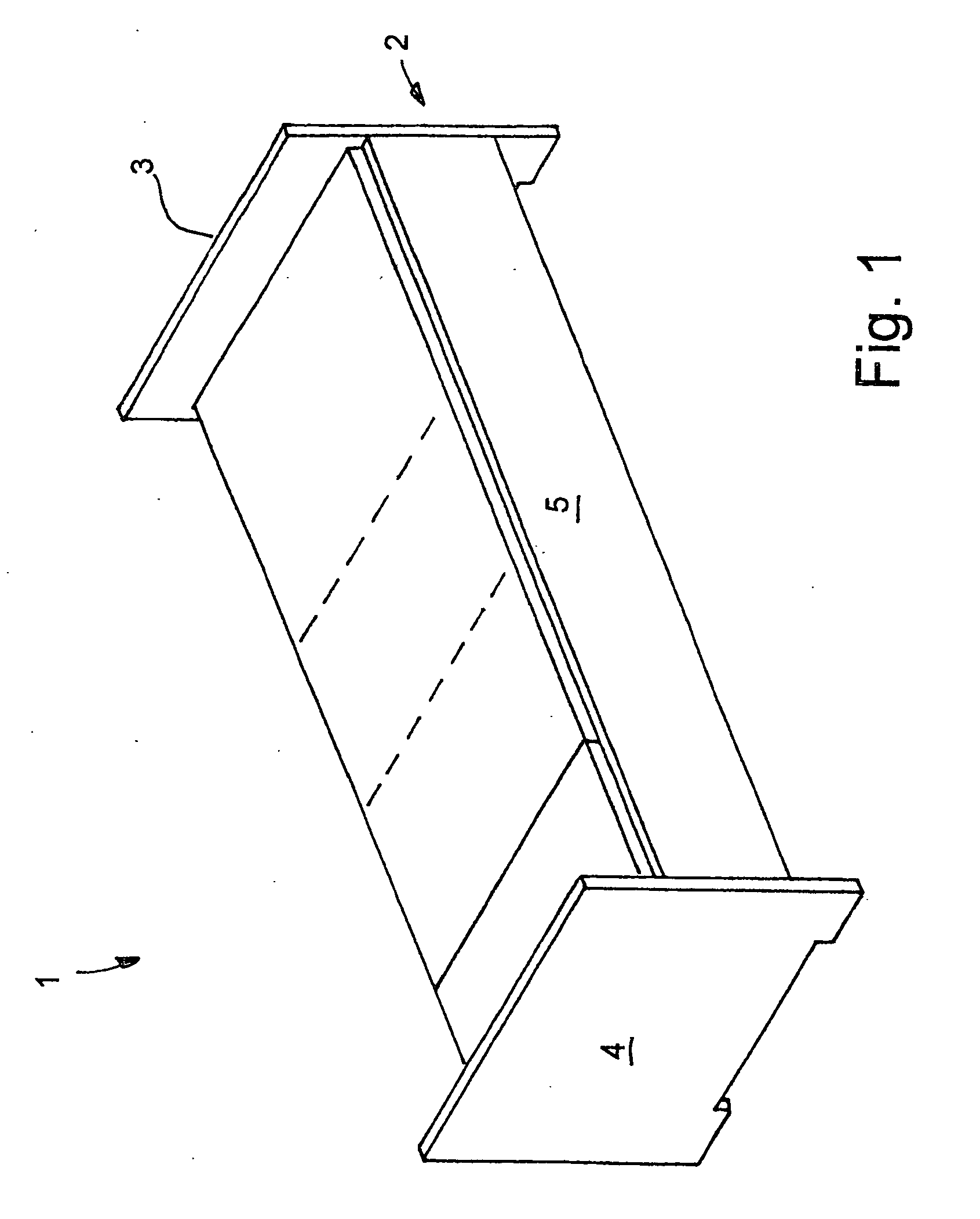

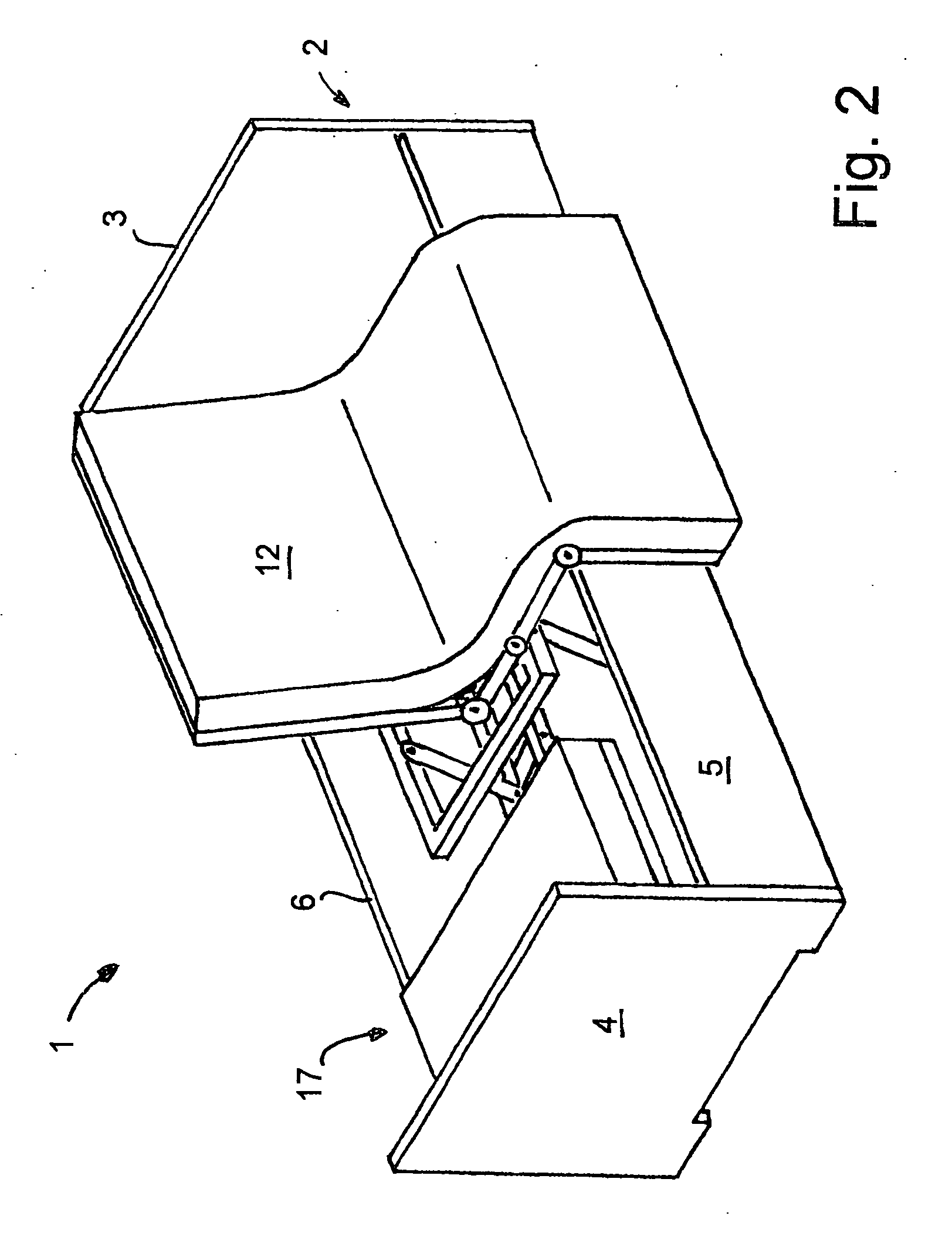

[0026]Referring now more particularly to the drawings, there is shown an illustrative hospital bed 1 in accordance with the invention, depicted in FIG. 1 in a sleeping position and in FIG. 2 in a sitting or chair position. A hospital bed 1 includes a bed border 2 with a head part 3, a foot part 4, and side walls 5,6. The side wall 5 facing the observer is in the sleeping position, in which it is spaced apart from the floor as shown such that a gap is formed between the lower edge of the side wall 5 and the floor so that nursing personnel are able to place the tips of their feet beneath the bed. The side wall 5 is movably supported for transfer into a position in which it is displaced downward, in the chair position of the hospital bed 1 as shown in FIG. 2. The moveable support of the side wall 5 is explicitly described, for example, in DE 199 12 937 A1.

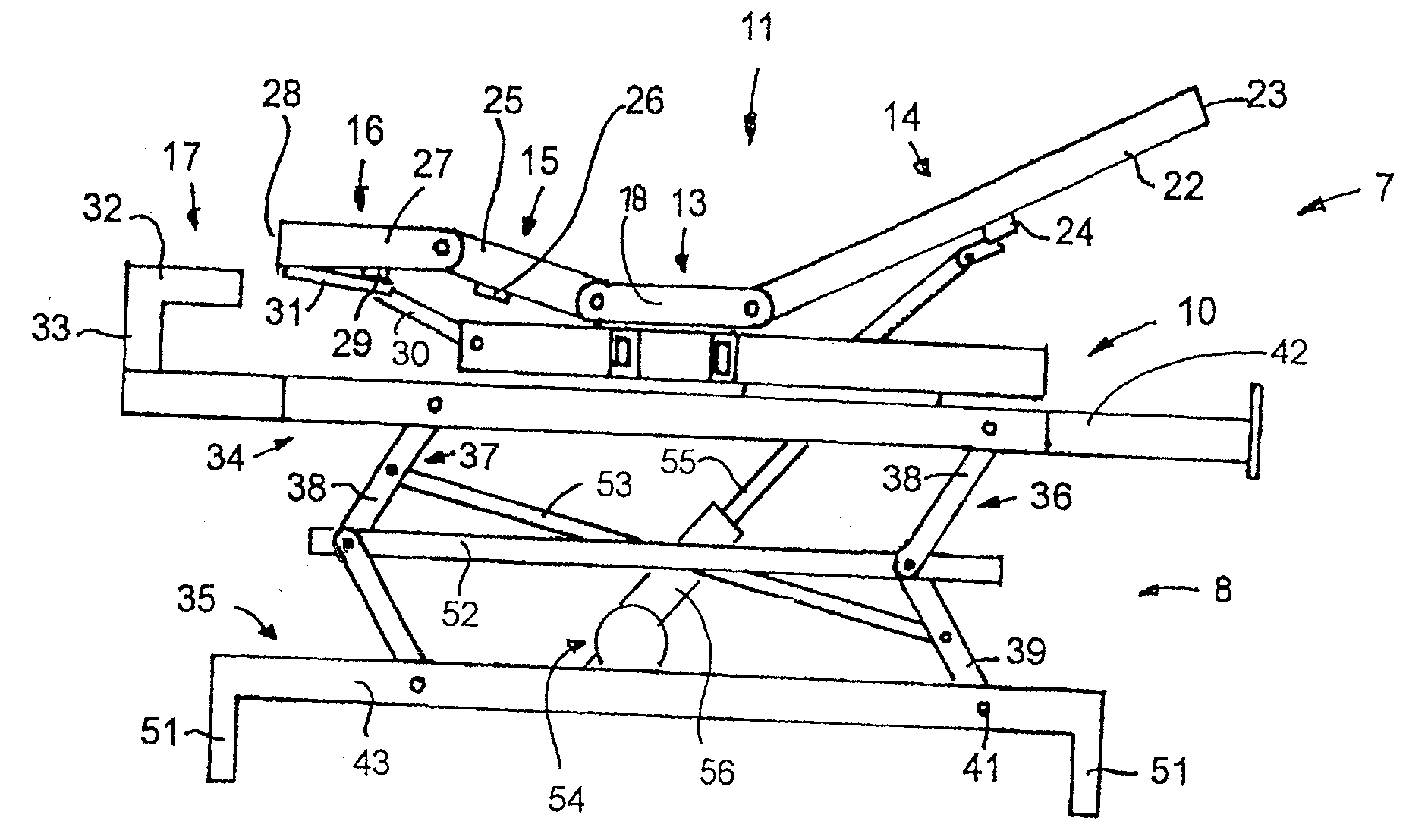

[0027]A bed frame 7 is located within the bed border 2, as depicted in FIG. 3. The bed frame 7 includes a height-adjustable base 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com