Ion implantation apparatus and ion implantation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

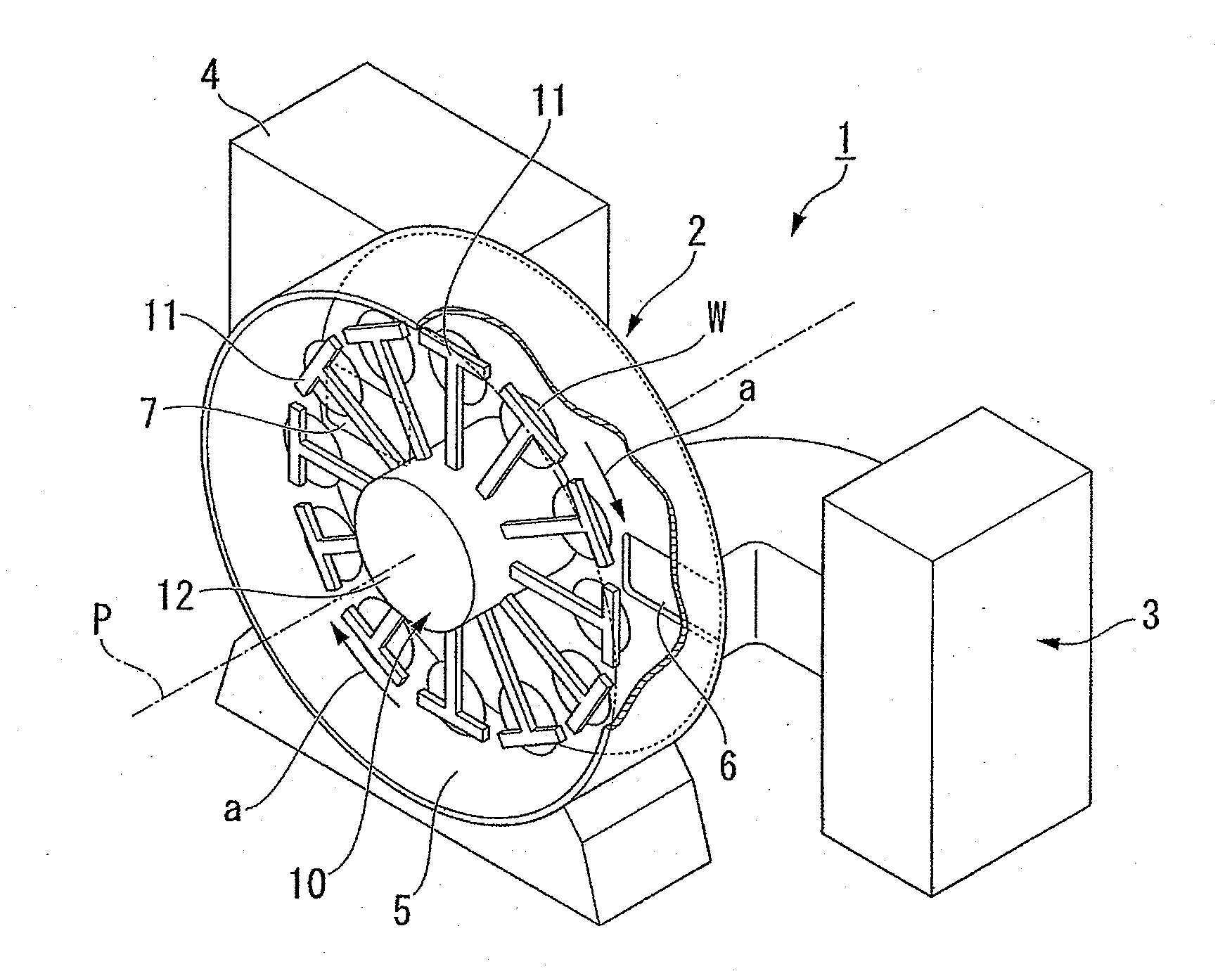

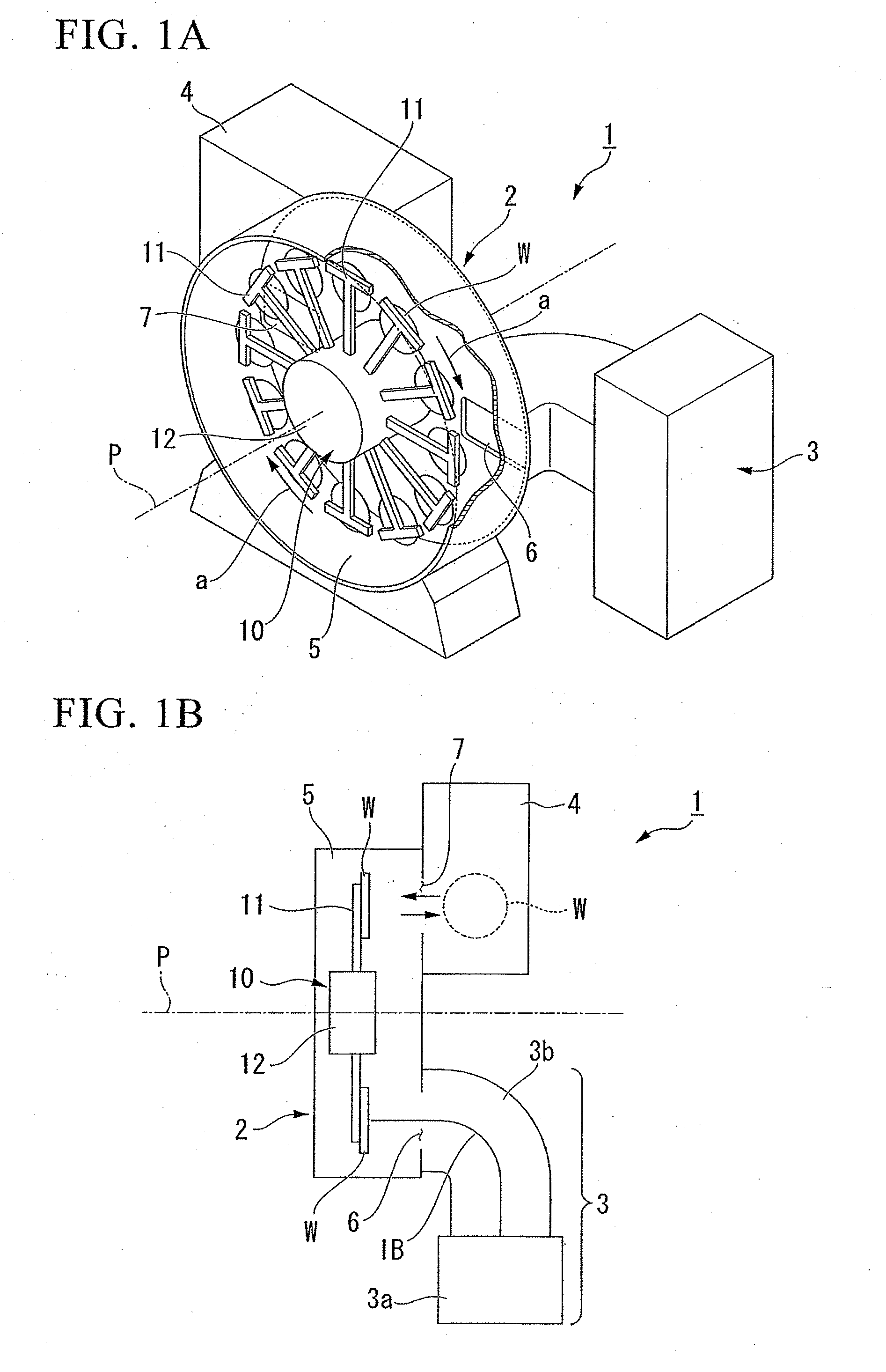

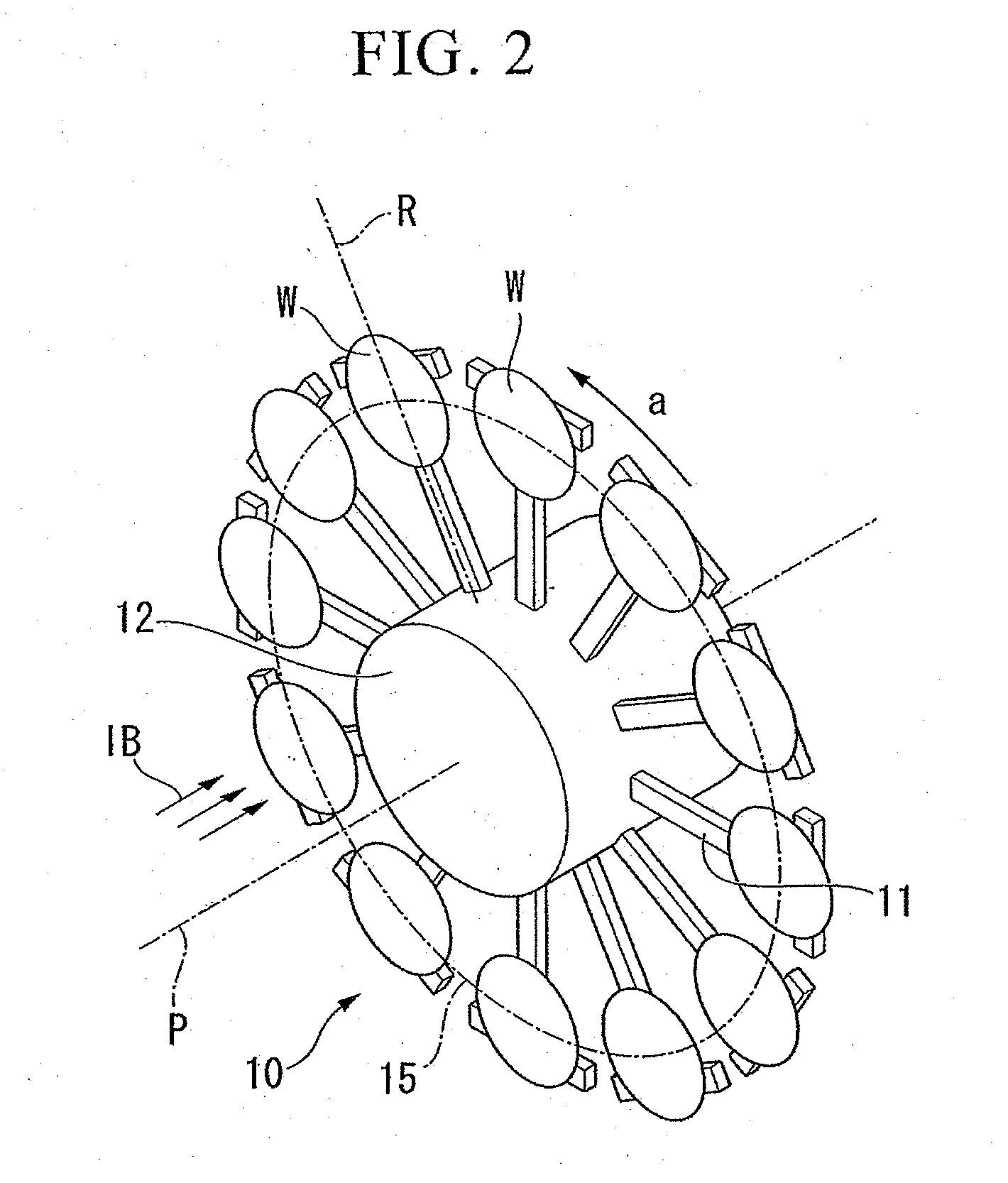

[0043]The ion implantation apparatus of an embodiment of the present invention is described below with reference to FIG. 1A to FIG. 8. Here, the ion implantation apparatus of the present embodiment is described as one which uses the SIMOX method to fabricate a SOI substrate by implanting oxygen ions into a silicon wafer. In all of the following drawings, the layer thicknesses and dimensional proportions of each component element are suitably varied in order to facilitate viewing of the drawing.

[0044]FIG. 1A and FIG. 1B are diagrams which show an ion implantation apparatus 1 of the present embodiment. FIG. 1A is a perspective view, and FIG. 1B is a schematic drawing which shows the operation of the ion implantation apparatus 1.

[0045]As shown in FIG. 1A, the ion implantation apparatus 1 is provided with an ion implanter 2 which conducts ion implantation relative to a wafer W, an ion beam generator 3 which generates the ion beam that irradiates the wafer W, and a wafer conveyor 4 which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com