Die casting machine and die casting method

a die casting machine and die casting technology, applied in the direction of mold control devices, manufacturing tools,foundry moulding apparatus, etc., can solve the problems of insufficient molten metal, no longer possible production, and each proposal has a problem, so as to achieve fast injection molding, fast speed value, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

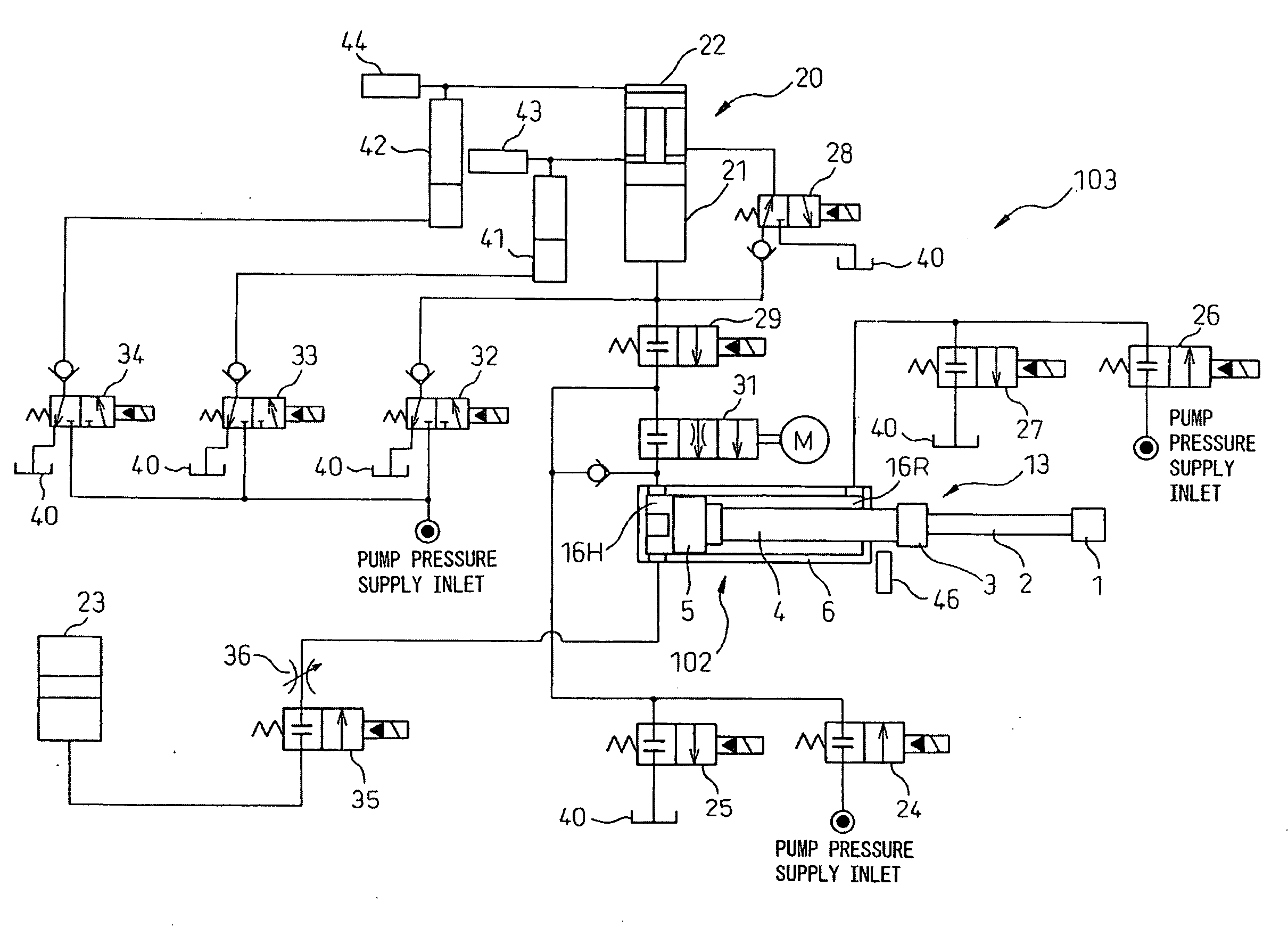

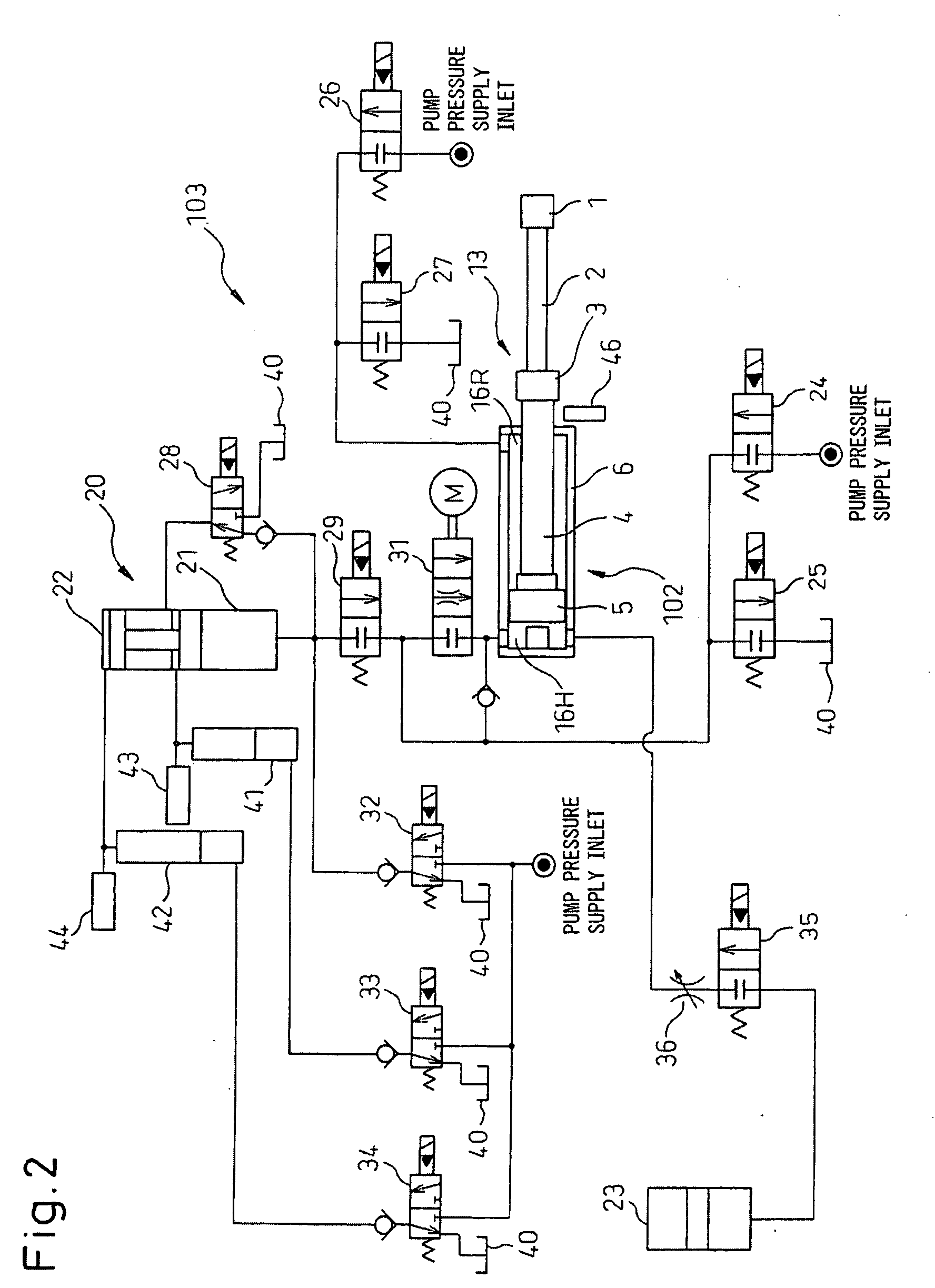

[0087]FIG. 2 illustratively shows the hydraulic circuit of a hydraulic device 103 in the present invention, which drives the injection cylinder 102. On the line on the inlet side of a head chamber 16H of the cylinder 6, a seventh valve 31 that controls the injection speed and the piston ACC (accumulator) 20 capable of discharging oil at a high flow rate for fast (high-speed) injection are provided, and in the present embodiment, that the piston ACC (accumulator) 20 has a preferred configuration is one of the characteristics. The piston ACC 20 is divided into two parts, that is, an upper part and a lower part, and a piston 221 in a fast pressure-raising piston ACC (accumulator)-B 22 at the upper part has a projection part 222 of a rod part and the projection part 222 presses the upper surface of a piston 211 of an injection piston ACC (accumulator)-A 21 at the lower part. In the fast pressure-raising piston ACC-B 22 at the upper part, a high-pressure gas (for example, 14 MPa) is accu...

third embodiment

[0108]FIG. 16 illustratively shows a hydraulic circuit of a hydraulic device 303 in the present invention, which drives the injection cylinder 102. On a connection inlet line to the head chamber 16H of the cylinder 6, the injection piston accumulator (ACC) 20 is provided so as to communicate fluidly therewith, which is capable of discharging at a high flow rate for fast injection via the fast speed adjusting valve (the seventh valve) 31 that controls the injection speed. In general, the cylindrical injection piston accumulator 20 is partitioned into two chambers by the piston 211 that slides and reciprocates in the piston accumulator 20, one of them is the hydraulic chamber 218 in which hydraulic oil is stored and the other is the gas chamber 217 in which gas is stored. The gas chamber 217 is provided with high-pressure gas from a gas bottle to press under pressure the piston 211 to supply the hydraulic oil in the hydraulic oil chamber to the hydraulic circuit of the hydraulic devic...

fourth embodiment

[0122]FIG. 24 is a chart representing the change of the injection speed, the injection pressure (pressure in the head chamber 16H of the injection cylinder 102), etc. with respect to the time progress, and the state of the piston rod, each valve, etc., at that time in the FIG. 14 is basically the same as FIG. 23 and the symbols etc. are the same as those in FIG. 23. The first, second, and third switching valves 75, 76, 77 in FIG. 23 do not exist in FIG. 24, and instead, the time chart of the filling force pattern adjusting valve 82 is shown. It is known from FIG. 24 that the filling force pattern adjusting valve 82 is maintained at a fixed valve opening degree after molding is started.

[0123]Next, the effects and working of the above-mentioned embodiments are explained. According to the die casting machine in the first embodiment of the present invention, the following effects can be expected.

[0124]In particular, in the die casting method or the die casting machine capable of fast i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com