Hanging ring integrated bottle preform large in cooling area of pouring gate column and forming mold of hanging ring integrated bottle preform

A technology of cooling area and glue mouth column, which is applied in the field of hanging bottle preforms, can solve the problems of affecting production efficiency, production cycle, intermediate material is not easy to cool, and affects blowing effect, so as to avoid excessive thickness of glue mouth column and improve production efficiency. The effect of improving and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

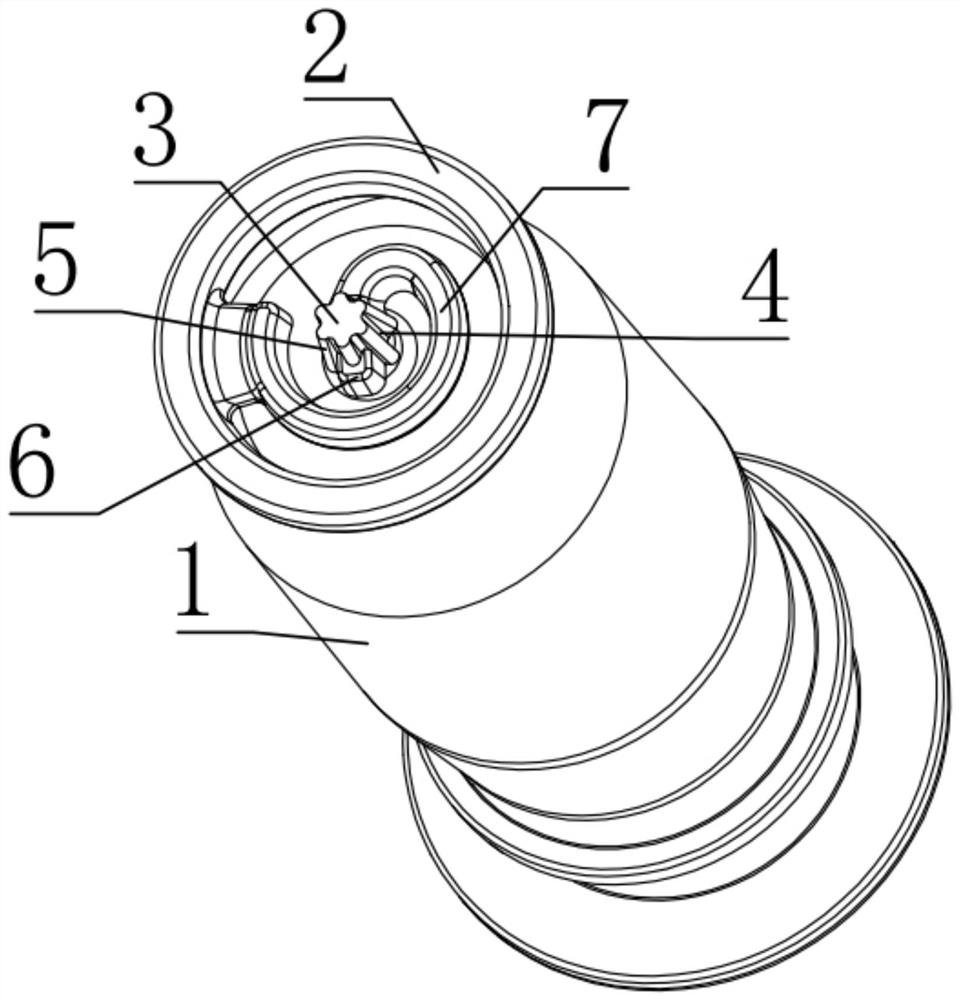

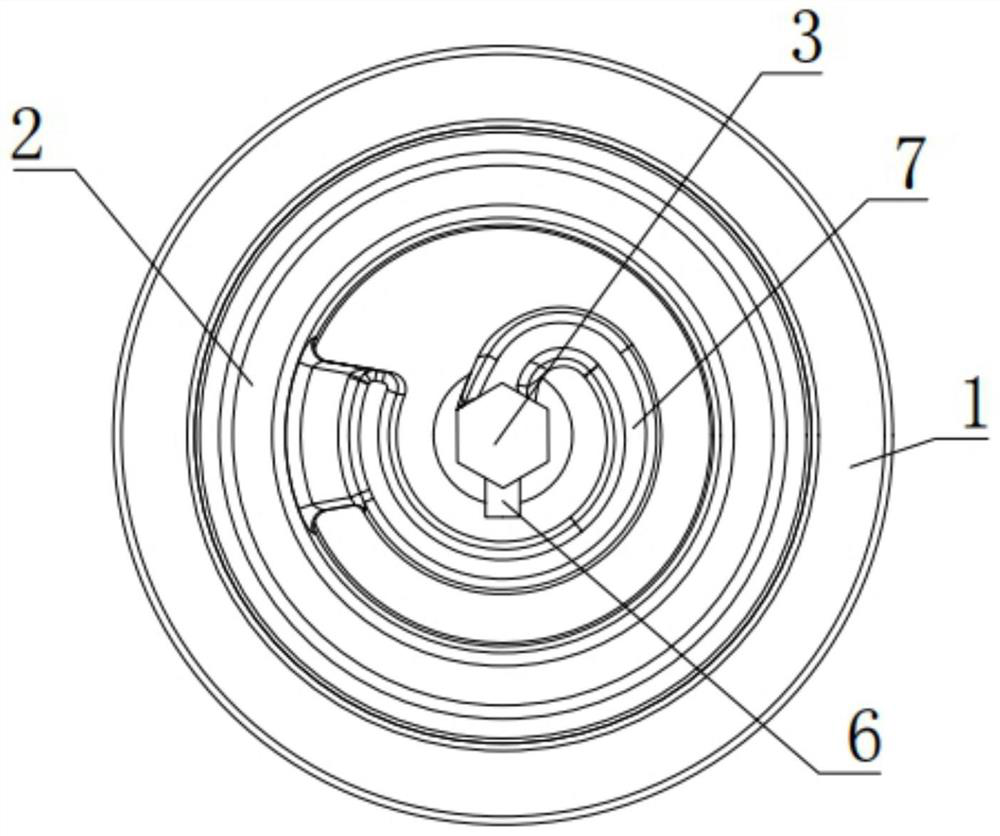

[0032] Such as figure 1 and figure 2 As shown, a ring-integrated preform with a large cooling area of the rubber mouth column includes a preform body 1, a suspension ring 2 and a rubber mouth column 3; the rubber mouth column 3 is arranged at the closed end of the preform body 1, The lifting ring 2 is connected to the rubber mouth column 3 through the connecting part 7, and the connecting part 7 is non-linearly arranged in the space formed between the rubber mouth column 3 and the lifting ring 2;

[0033] The glue hole post 3 is a special-shaped column structure with a cooling area larger than the cylindrical glue port post 3 .

[0034] The cross-section of the rubber port post 3 is tooth-shaped.

[0035] The rubber mouth column 3 is cylindrical, and the rubber mouth column 3 is evenly distributed with 6 cooling grooves 4 along the circumference, and protruding teeth 5 (6 teeth) are formed between two adjacent cooling grooves 4 .

[0036] The preform body 1, the rubber m...

Embodiment 2

[0042] Such as image 3 As shown, the difference between this embodiment and embodiment 1 lies in that the glue port post 3 is a prism.

[0043] It is preferably a regular five or hexagonal prism. The surface area of the prism is greater than the surface area of the cylinder. Furthermore, the cooling area of the prismatic rubber mouth column 3 is larger, the heat dissipation effect is better, and it is not easy to draw.

Embodiment 3

[0045] Such as Figure 4 and Figure 5 As shown, the present embodiment is a forming mold for producing the ring-integrated preform with a large cooling area of the rubber port post in Example 1, including a core 8, a core sleeve 9, a first half block 10, a forming Die 11, second half block 12 and gate mold core 13, the bottom center of gate mold core 13 is provided with injection port 14, the bottom of gate mold core 13 is provided with second half block 12, gate mold The mating surface of the core 13 and the second half block 12 forms the forming cavity of the suspension ring 2 and the connecting part 7, and one end of the forming cavity of the lifting ring 2 communicates with the forming cavity of the connecting part 7; the bottom of the gate core 13, the second half The molding cavity of the plastic mouth column 3 is formed between the top of the block 12 and the top of the core 8, and the molding cavity of the plastic mouth column 3 is connected with the molding cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com