Method and device for cooling beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

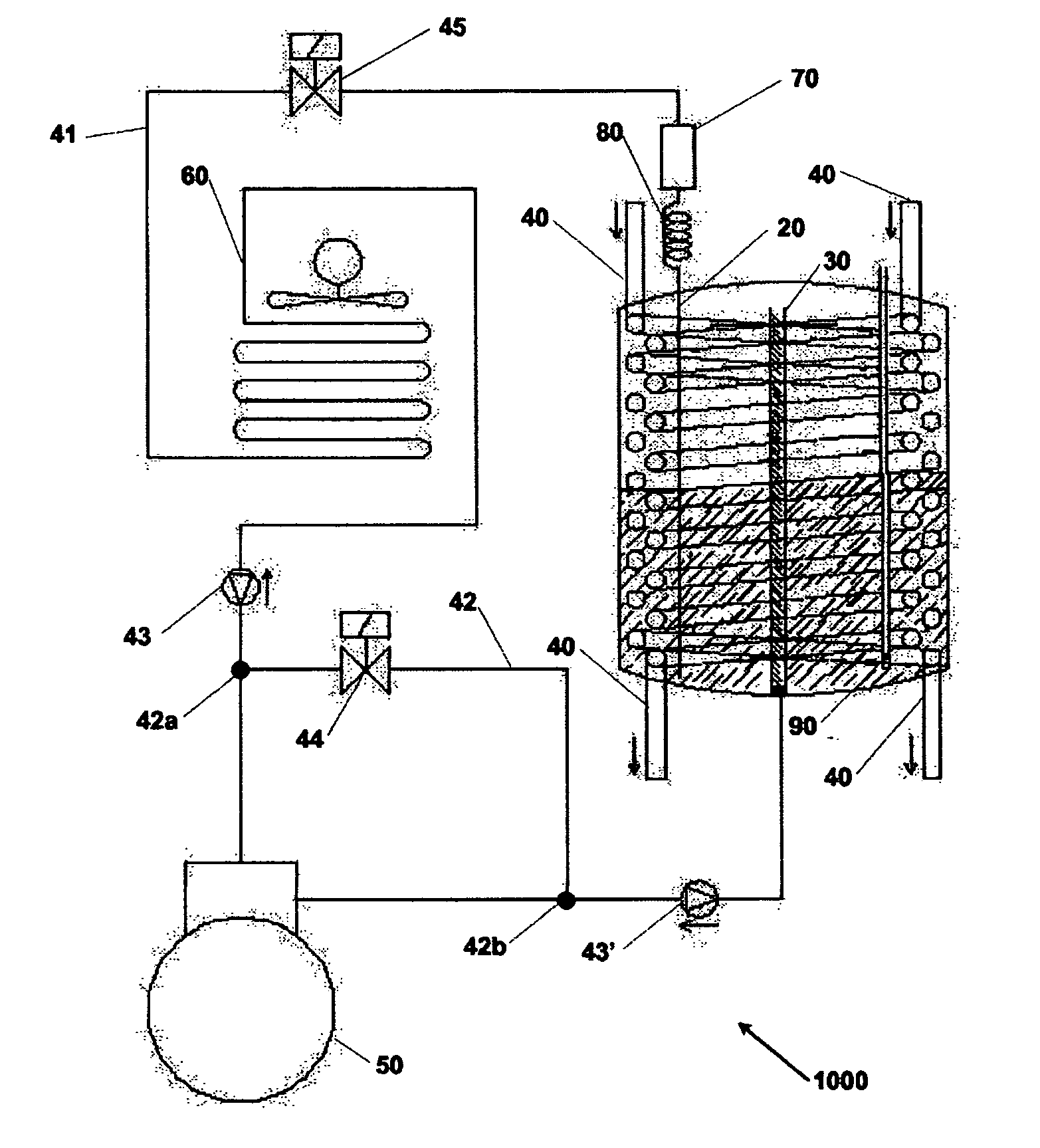

[0038]FIG. 1 is a simplified view of a beverage cooling device of the prior art in which a line 100 (for example a coil) transporting a beverage is immersed in a water bath containing ice.

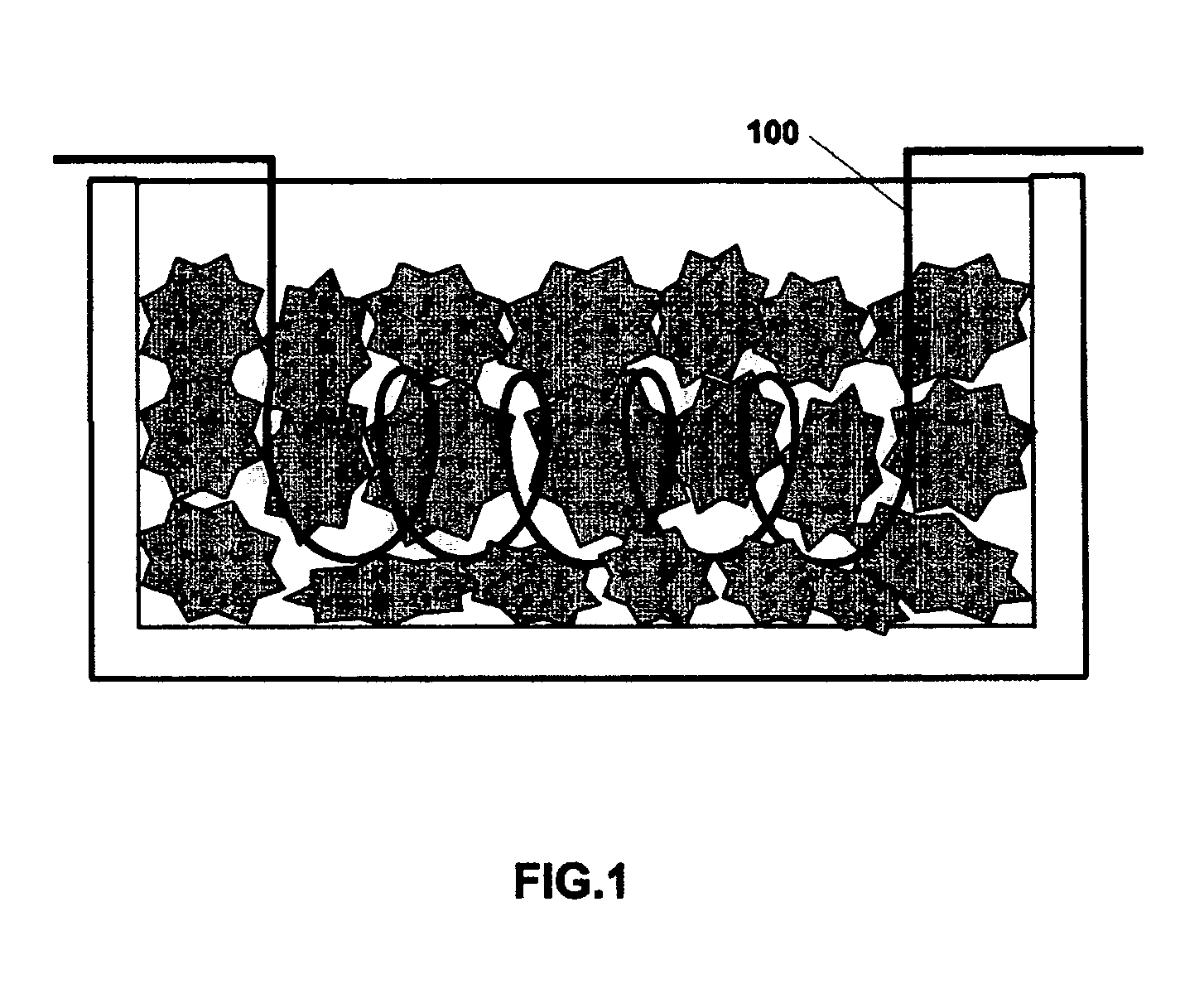

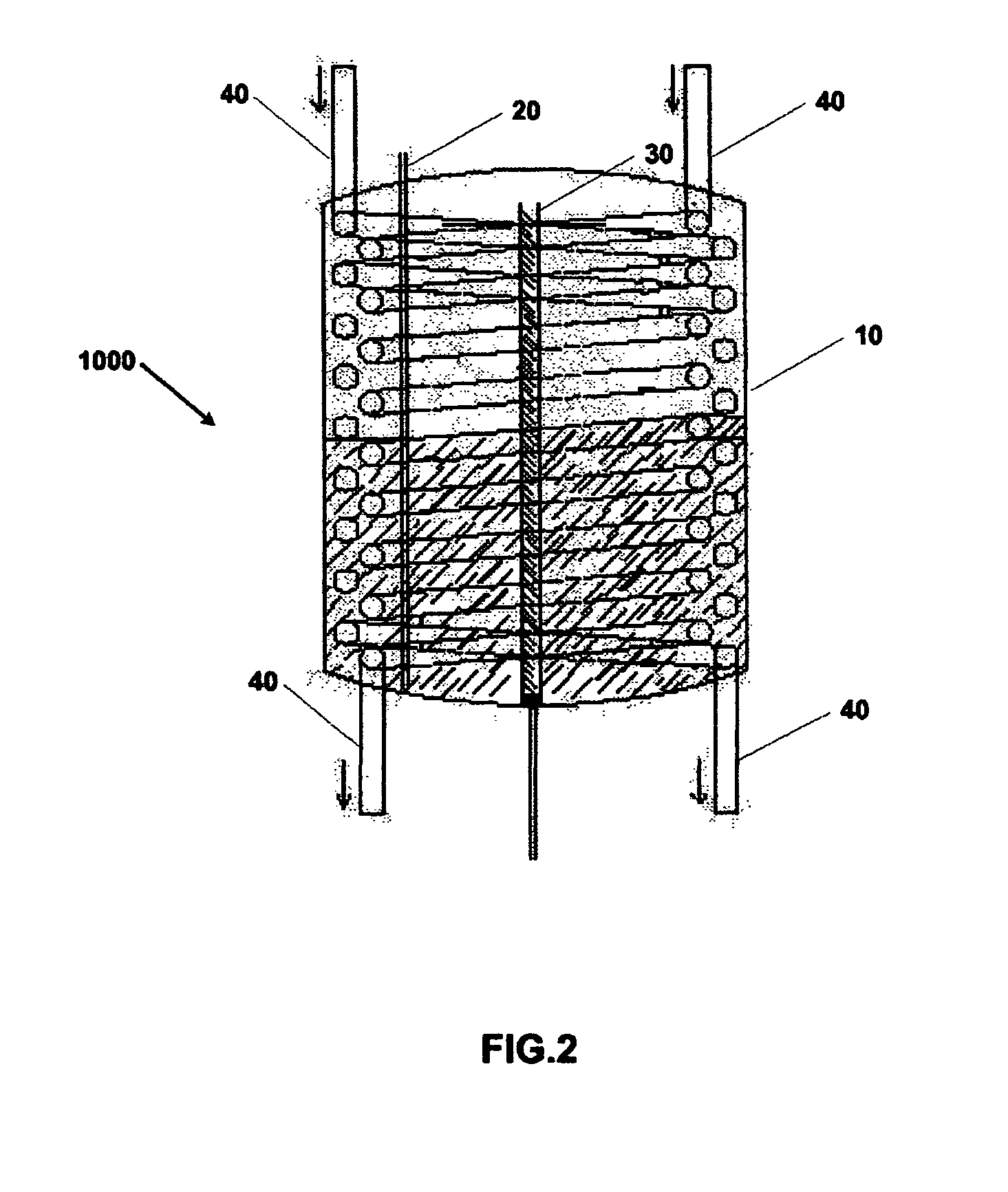

[0039]FIG. 2 is a diagram showing the general principle of one operating mode of a beverage dispenser according to the invention. The dispenser 1000 comprises:[0040]a source of refrigerant (such as a conventional refrigerating circuit using for example R22, R404 or R407, or a liquefied gas cylinder containing for example CO2, etc . . . );[0041]a lagged tank 10, in the form of cylinder 28 cm in diameter and 40 cm in height made of sheet metal 4 mm in thickness designed to contain said refrigerant in the liquid form in its lower part and to allow said refrigerant to evaporate, and designed to contain the refrigerant in gaseous form in its upper part;[0042]a first line 20 for transporting the refrigerant in liquid form in the lower part of the tank 10;[0043]a second line 30 designed to withdraw the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com