System and method for manufacturing carbon nanotubes

a carbon nanotube and manufacturing system technology, applied in the field of nanotechnology, can solve the problems of not being widely used, not being able to integrate carbon nanotubes into commercial products, and suffering from conventional methods so as to reduce the cost of carbon nanotube manufacturing, eliminate or reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]In describing preferred embodiments of the present invention illustrated in the Figures, specific terminology is employed for the sake of clarity. The invention, however, is not intended to be limited to the specific terminology so selected, and it is to be understood that each specific element includes all technical equivalents that operate in a similar manner to accomplish a similar purpose.

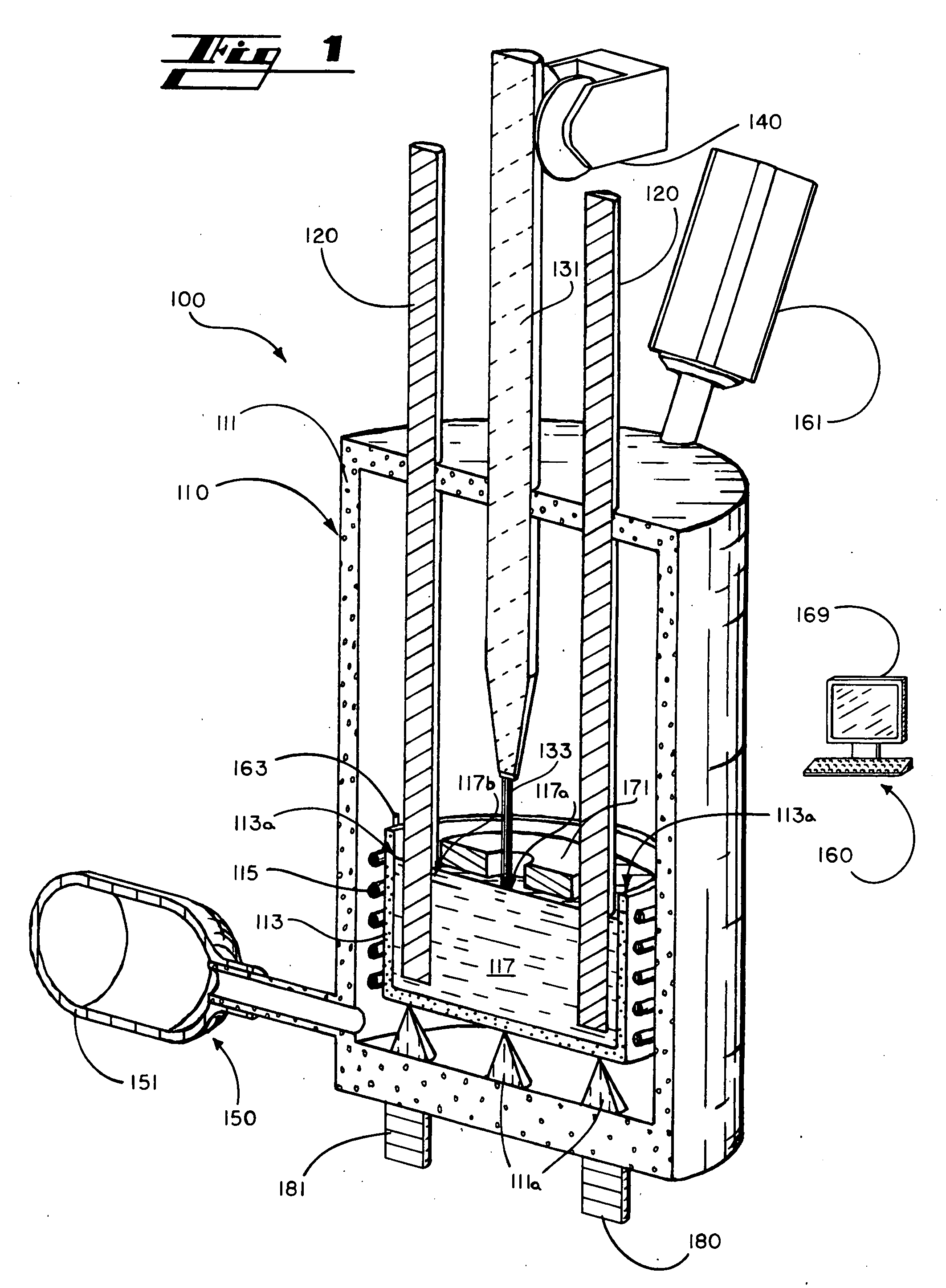

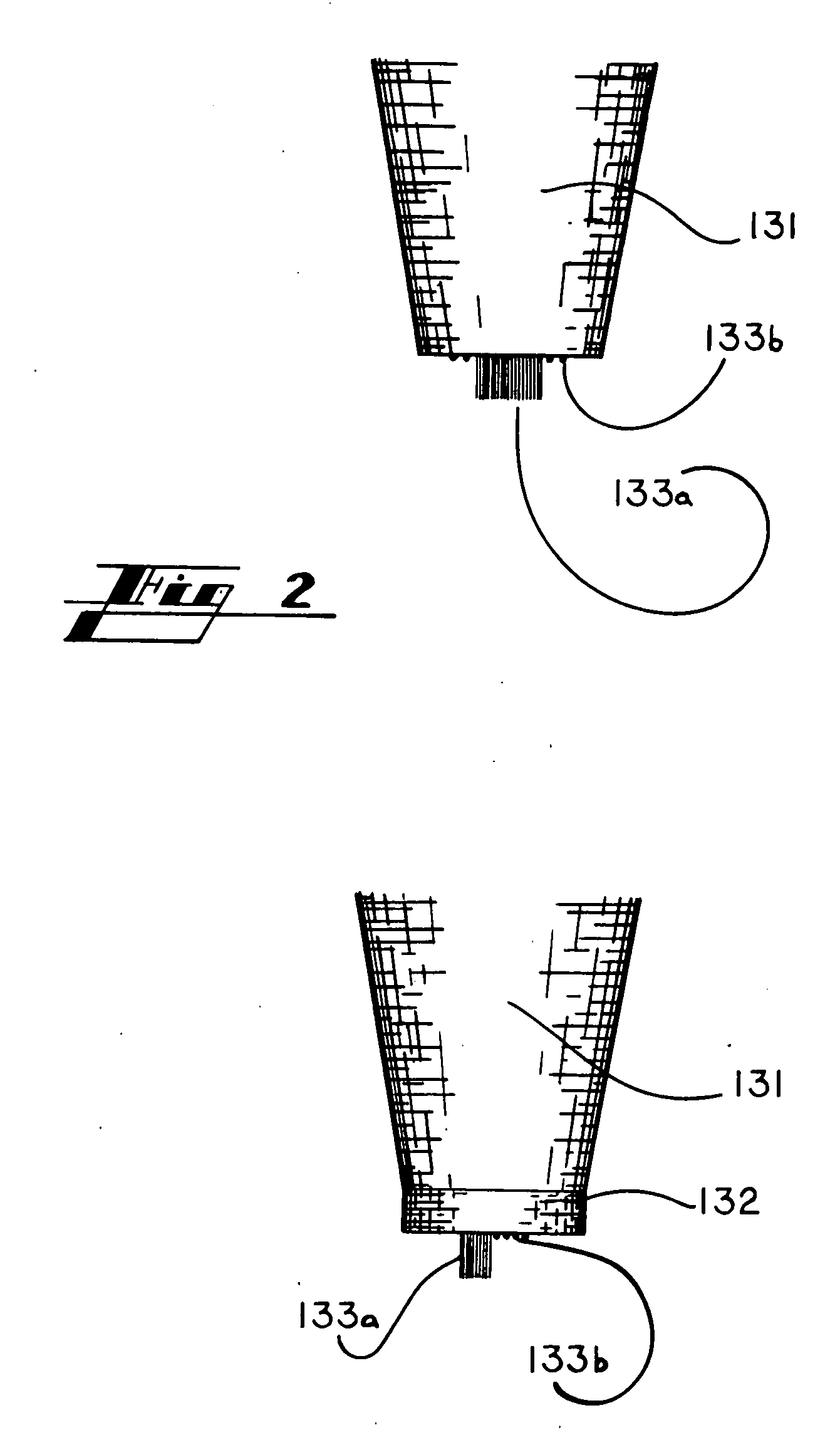

[0024]In that form of the preferred embodiment of the present invention chosen for purposes of illustration, FIGS. 1-5 show system 100 for manufacturing carbon nanotubes including means 110 for creating flux melt 117, means 120 for supplying carbon to flux melt 117, means 130 for contacting nucleation site 133 of probe 131 with flux melt 117, and means 140 for extracting probe 131 from flux melt 117.

[0025]Means 110 for creating flux melt 117 is preferably formed as furnace 111 having crucible 113 disposed therein, such as mounted to thermal isolation means 111a of furnace 111, and one or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com