Multi-stage piston compressor

a piston compressor and multi-stage technology, applied in the direction of piston pumps, positive displacement liquid engines, machines/engines, etc., can solve the problem of problems such as the application of piston compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

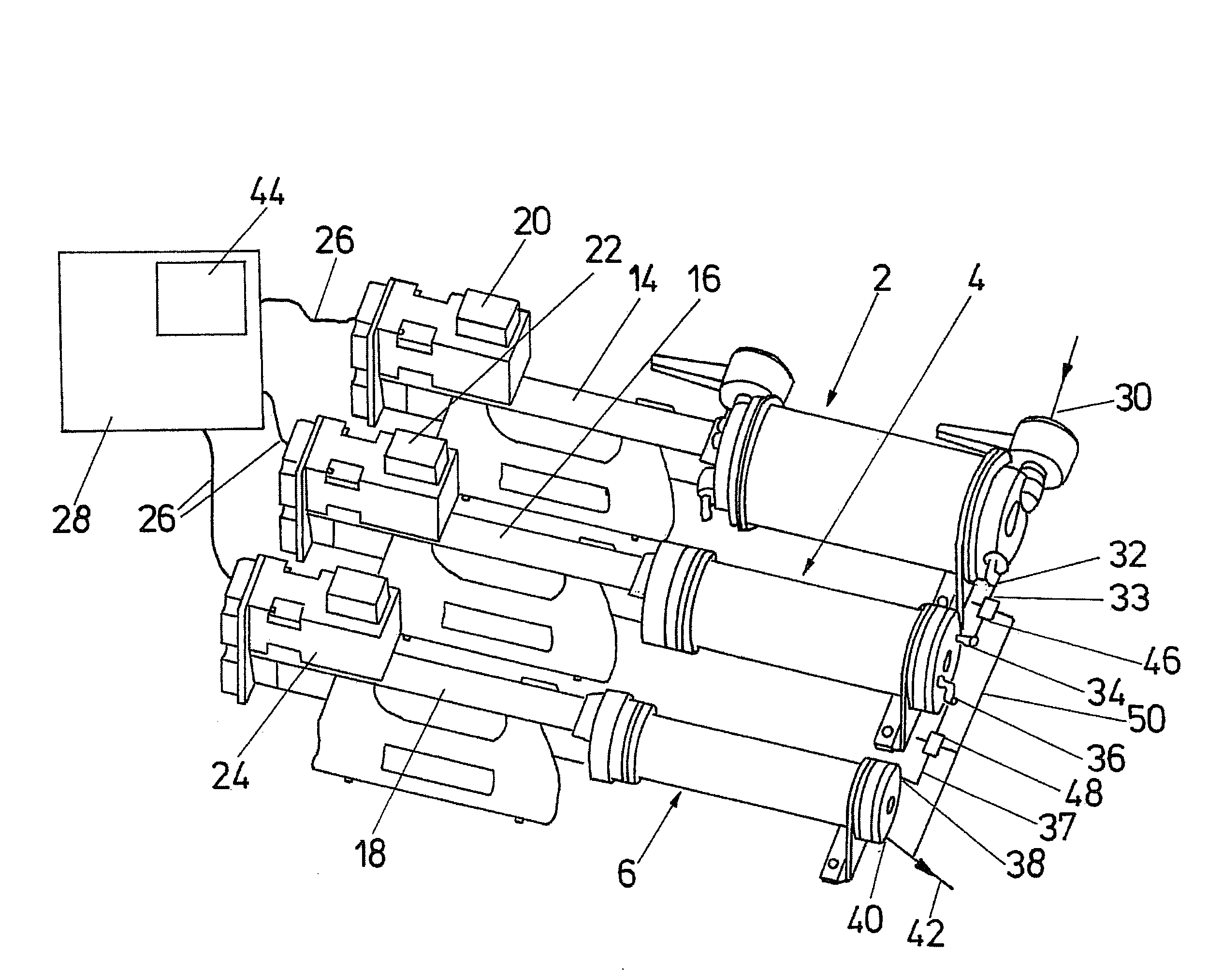

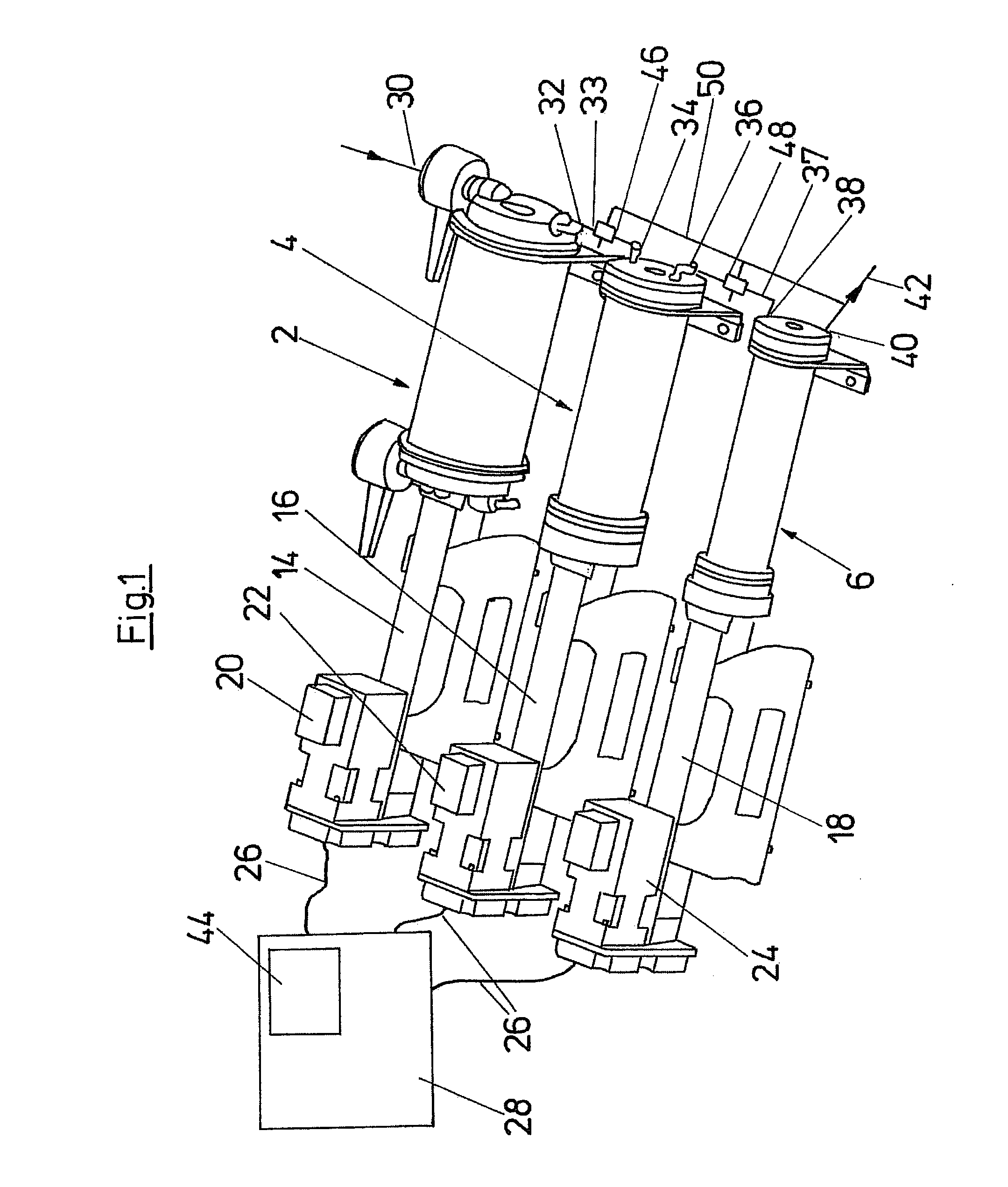

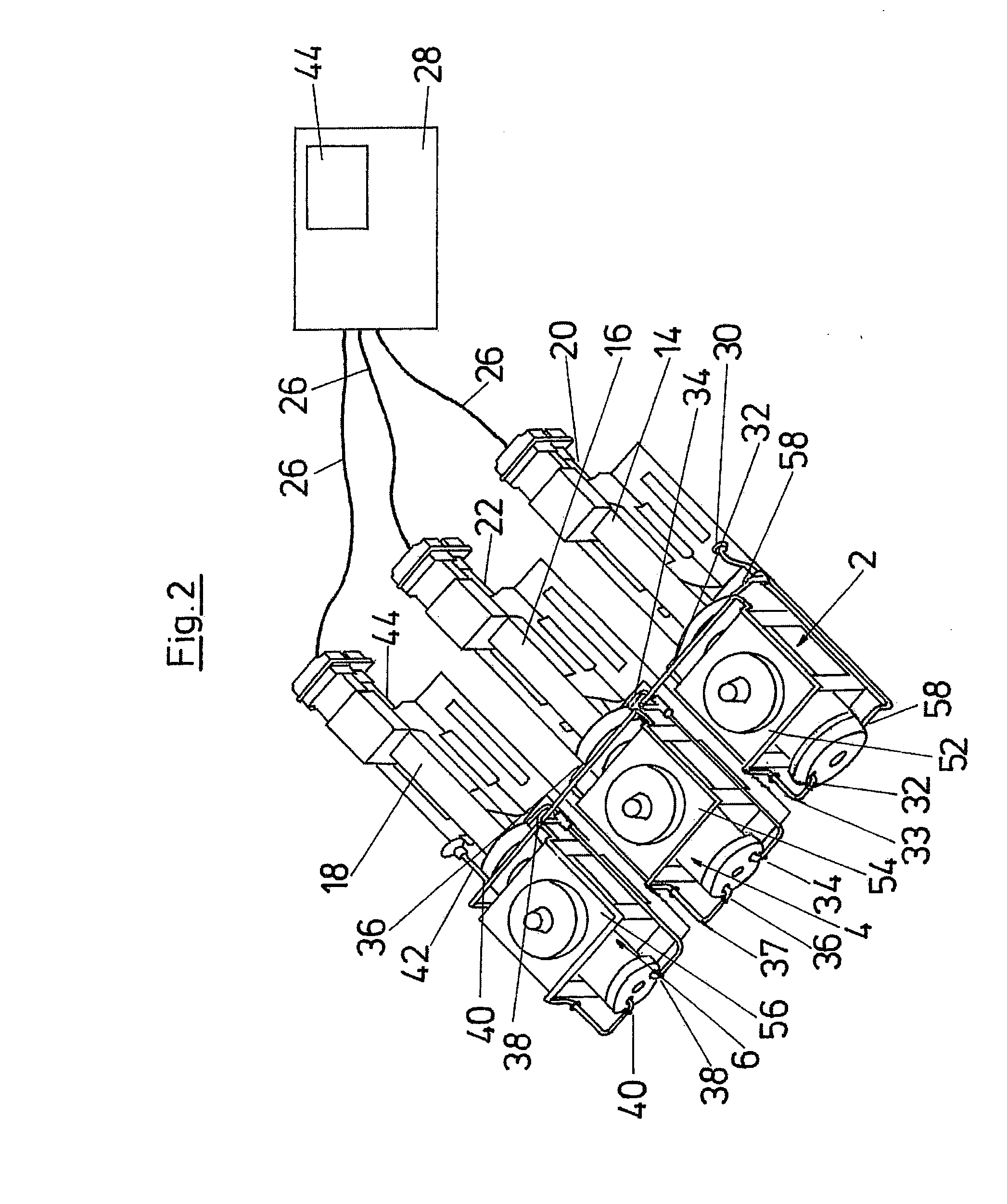

[0020]The piston compressor shown in FIG. 1 is designed in a three-stage manner and accordingly comprises three piston-cylinder units 2, 4 and 6. The piston-cylinder units 2, 4, 6, as is shown in FIG. 4, consist in each case of a cylinder 8 which is cylindrical in cross section and of a piston 10 which is linearly movable therein. The piston 10 is connected to a piston rod 12. The cylinder 8 in a known manner comprises inlet valves and outlet valves, which may be designed as spring-biased check valves, which are suitably connected to the entry conduits and exit conduits.

[0021]According to the invention, each piston-cylinder unit 2, 4, 6 has its own linear drive 14, 16, 18. The piston-cylinder unit 2 comprises a linear drive 14 which is connected to the piston rod 12 of the piston cylinder unit 2, in order to move its piston 10 linearly in the inside of the cylinder 8. Correspondingly, the piston-cylinder unit 4 is connected to its own linear drive 16, which moves the piston 10 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com