Process for Removing Water and Water Soluble Contaminants From Biofuels

a biofuel and water soluble technology, applied in the direction of biofuels, chemistry apparatus and processes, fuels, etc., can solve the problems of complex mixtures, biofuel processing is not without problems, and the processing of biofuels and biofuel feedstocks is not without problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

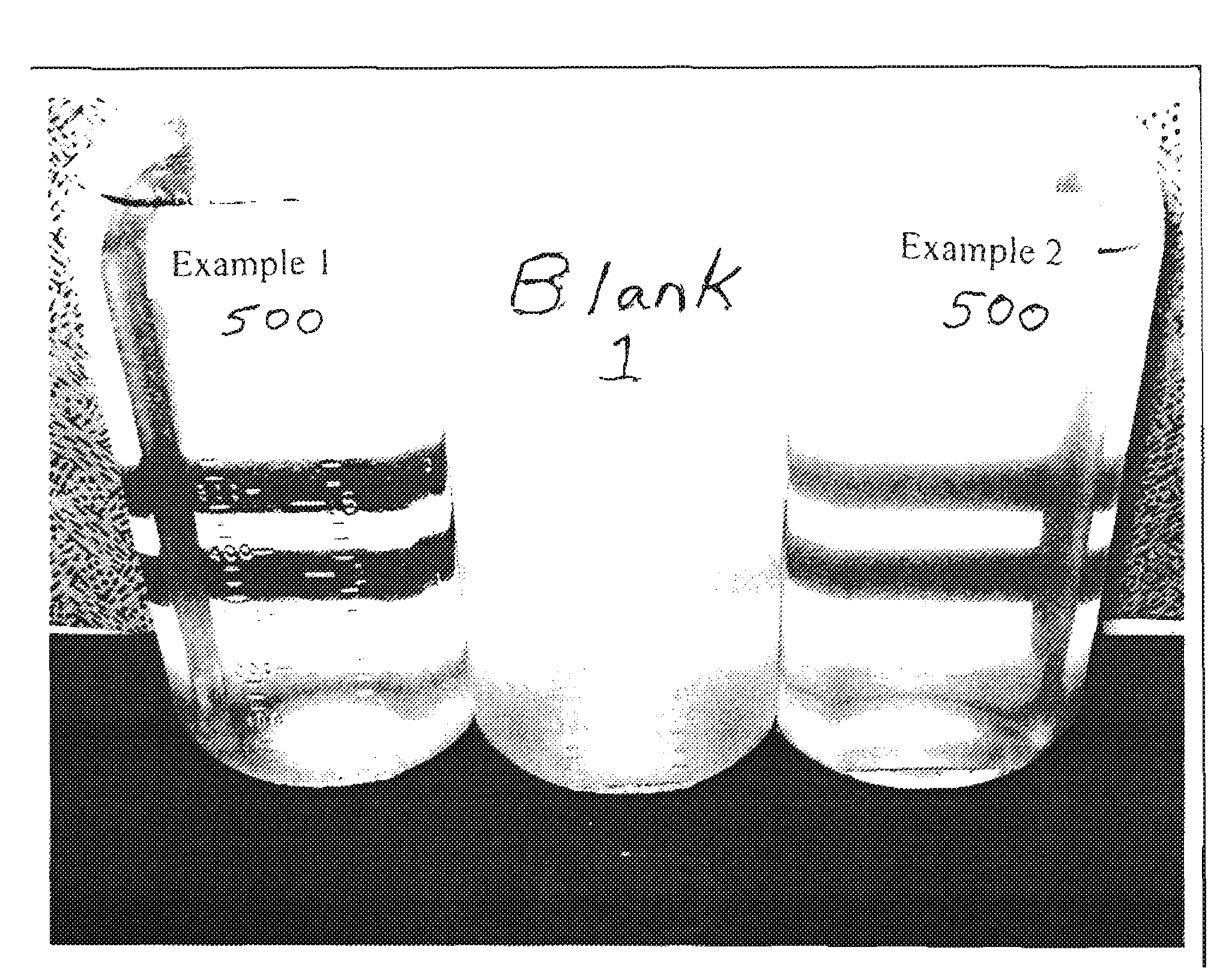

example 1

[0030]A sample of a biodiesel prepared from meth ester palm oil and having a an initial haze rating determined according to ASTM D-4176 of 4 was tested by admixing the sample with the demulsifiers set forth below in Table 1. The resulting haze values and the times noted are also set forth in the tables. A visual comparison is presented in FIG. 1 for Sample A. The Samples used were:[0031]Sample A is a blend of oxyalkylated acid catalyzed amylphenol resin and oxyalkylated polypropylene glycol available under the trade designation BIO9973 Additive from the Baker Petrolite Corporation;[0032]Sample B is a blend of oxyalkylated nonylphenol resin and an oxyalkylated acid catalyzed butylphenol resin available under the trade designation BIO-9971 Demulsifier from the Baker Petrolite Corporation;[0033]Comparative Sample C is a blend of oxyalkylated base catalyzed butyl / nonyl phenol resin, oxyalkylated base catalyzed butylphenol resin, oxyalkylated base catalyzed amylphenol resin, and oxyalkyl...

example 2

[0035]A sample of a biodiesel prepared from methyl ester palm oil and having a an initial haze rating determined according to ASTM D-4176 of 6 was tested by admixing the sample with the demulsifier set forth below in Table 4. The resulting haze values and the times noted are also set forth in Table 4. A visual comparison is presented in FIG. 1.

TABLE 401530123424Sample IDminminminhrhrhrhrhrSample A65554432500 ppmHazeRatingsBlank66666666HazeRatings

example 3

[0036]Chicken fat was rendered to produce an oil. The resultant oil was treated with methanol and a caustic catalyst at from about 140 to about 145° F. to transesterify the oil to produce a very wet biodiesel. The wet biodiesel was treated with 250 ppm Sample B. The biodiesel cleared very quickly and water coalesced and was collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com