Lamp Tube having Bent Segments

a technology of lamp tubes and segments, which is applied in the direction of discharge tubes/lamp details, discharge tubes, luminescent screens of discharge tubes, etc., can solve the problems of insatiable luminance efficiency of such lamp tubes, shortages of available lamp tubes, and blockage of portions of light emitted from them, etc., and achieve the effect of maximum luminance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

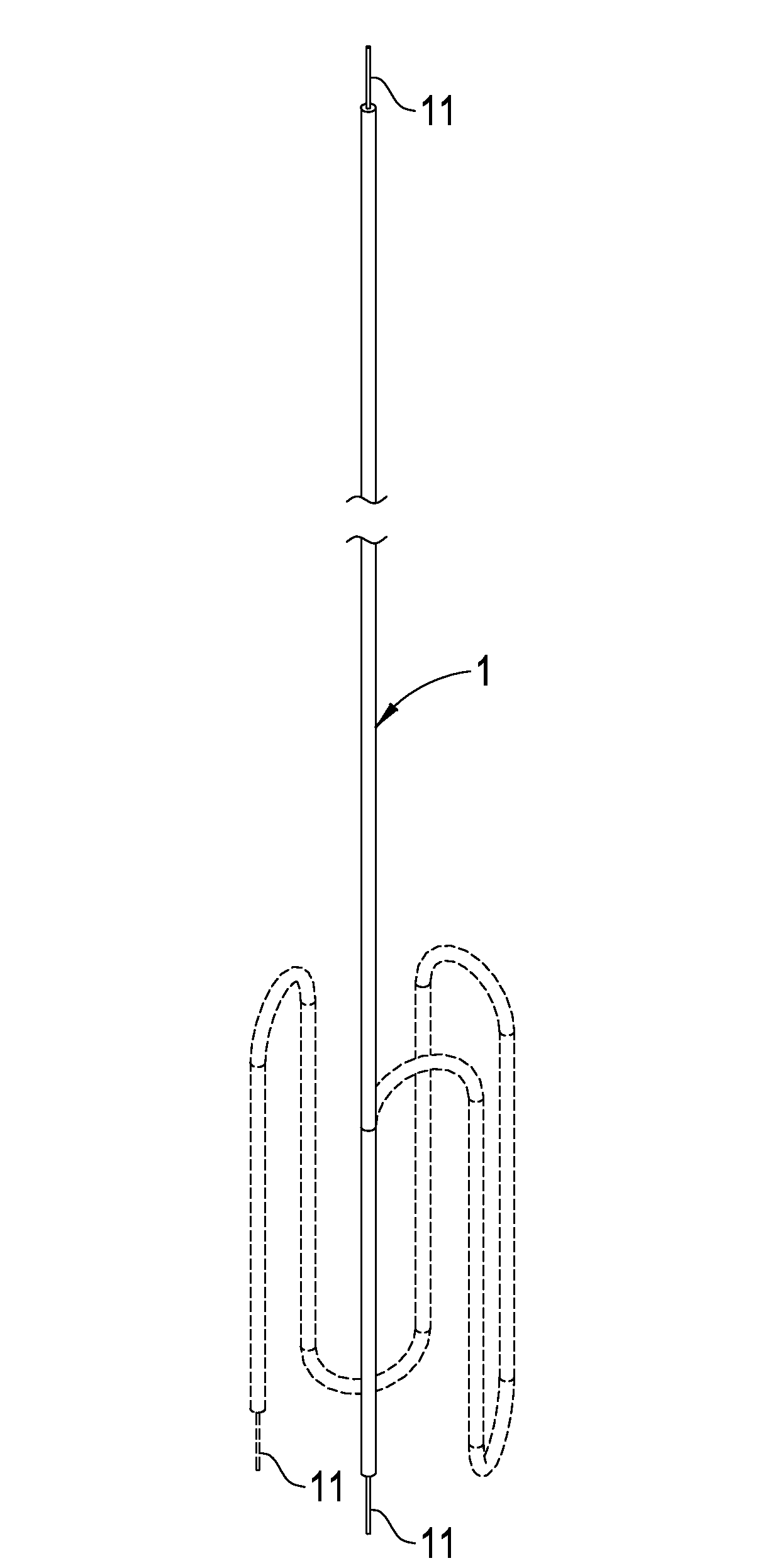

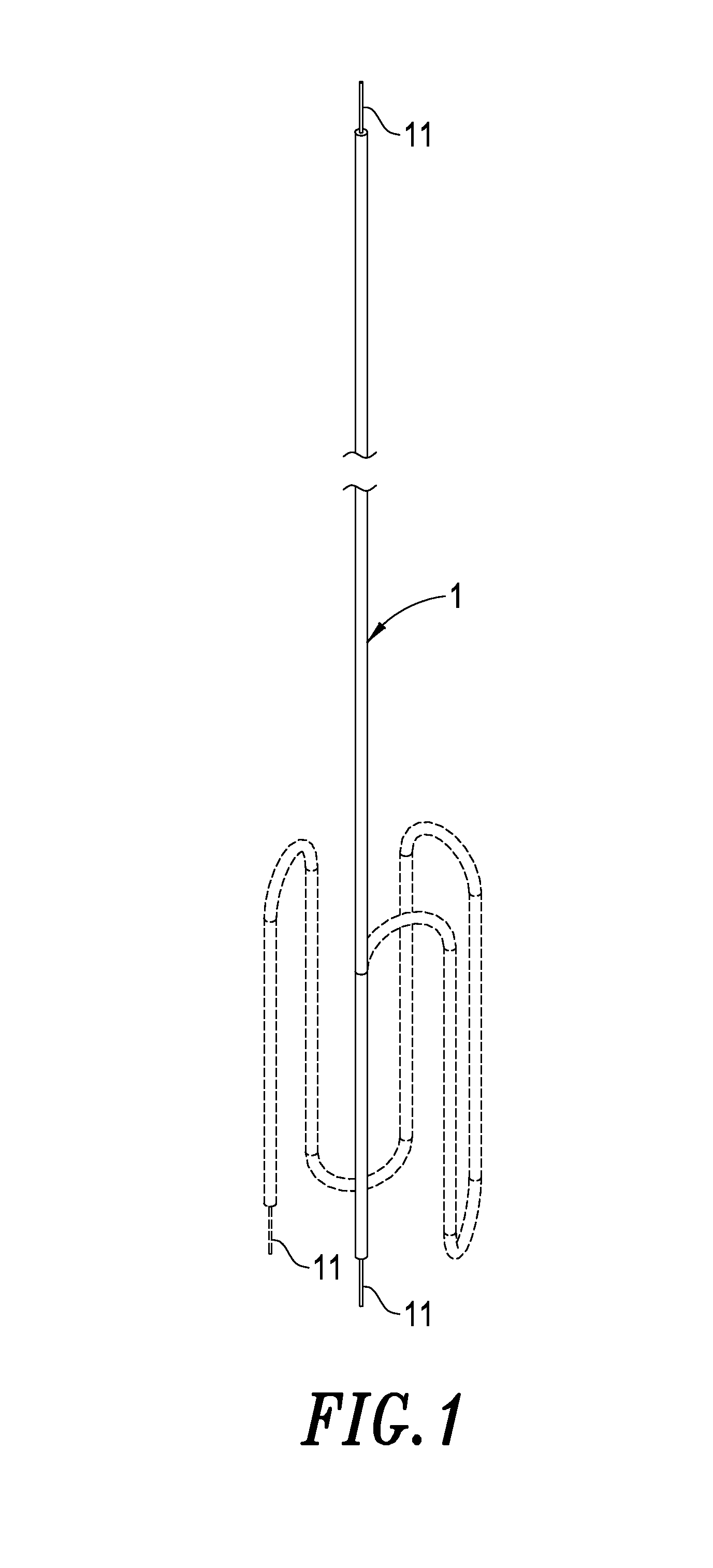

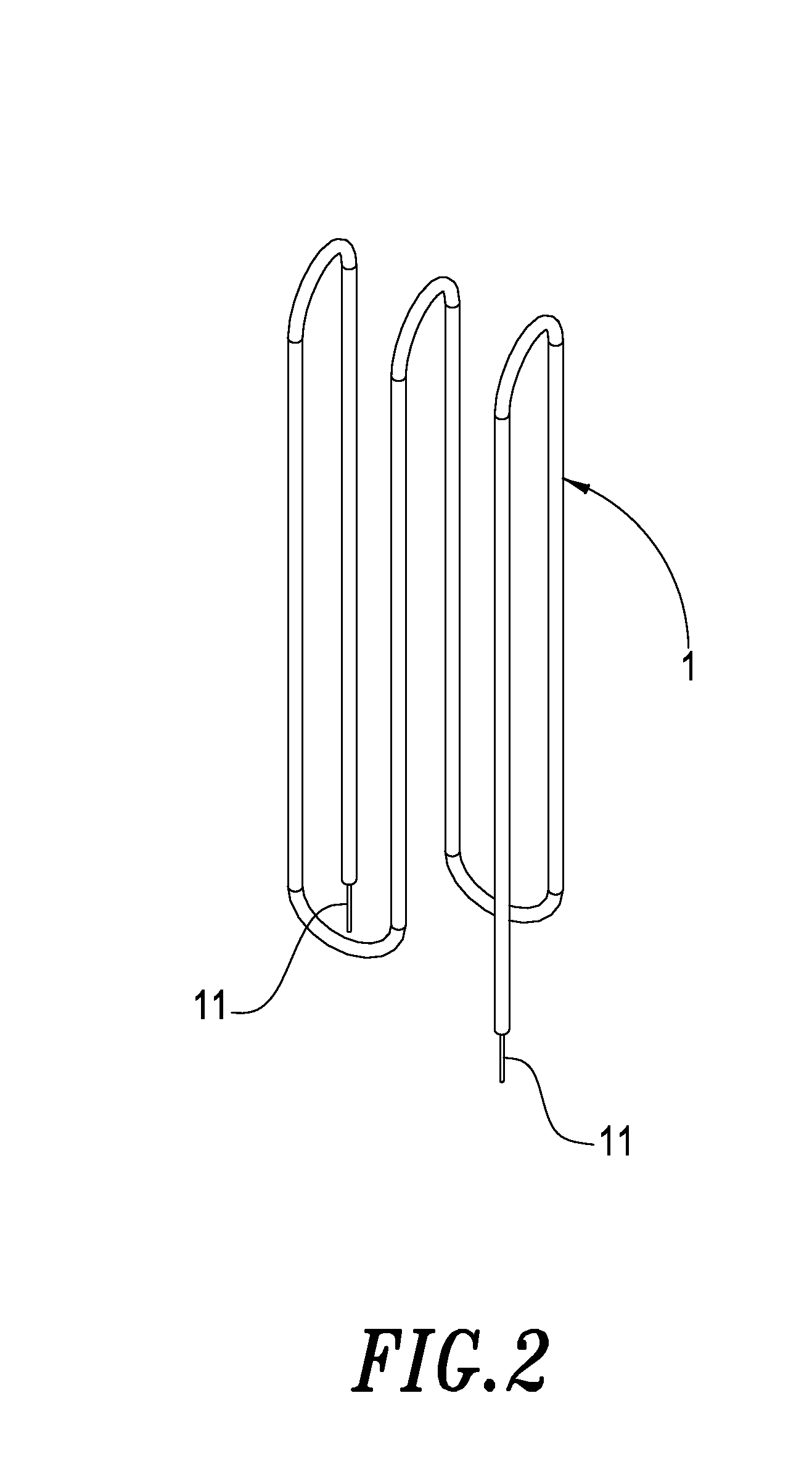

[0014]Referring to FIG. 1, a lamp tube having bent segments according to the present invention is shown therein. As shown, the lamp tube having bent segments has a lamp tube body 1, which takes a straight tubular shape. The lamp tube body 1 has an inner wall, on which a layer of fluorescent material (not shown) is pre-coated. The lamp tube body 1 further has a first and second ends, on each of which an electrode 11 is bonded thereto. An adequate amount of mercury and inactive gases is sealed within the lamp tube body 1. In this invention, the lamp tube body 1 is heated and then bent at portions desired to be bent to preliminary form the bent segments thereof. After being cooled, the lamp tube body 1 is actually formed with the bent segments. In a first embodiment, the lamp tube body 1 is bent to having a three-dimensional form (such termed herein), shown in FIG. 1. In a second embodiment, the lamp tube body 1 is bent to having another three-dimensional form, shown in FIG. 2. The lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com