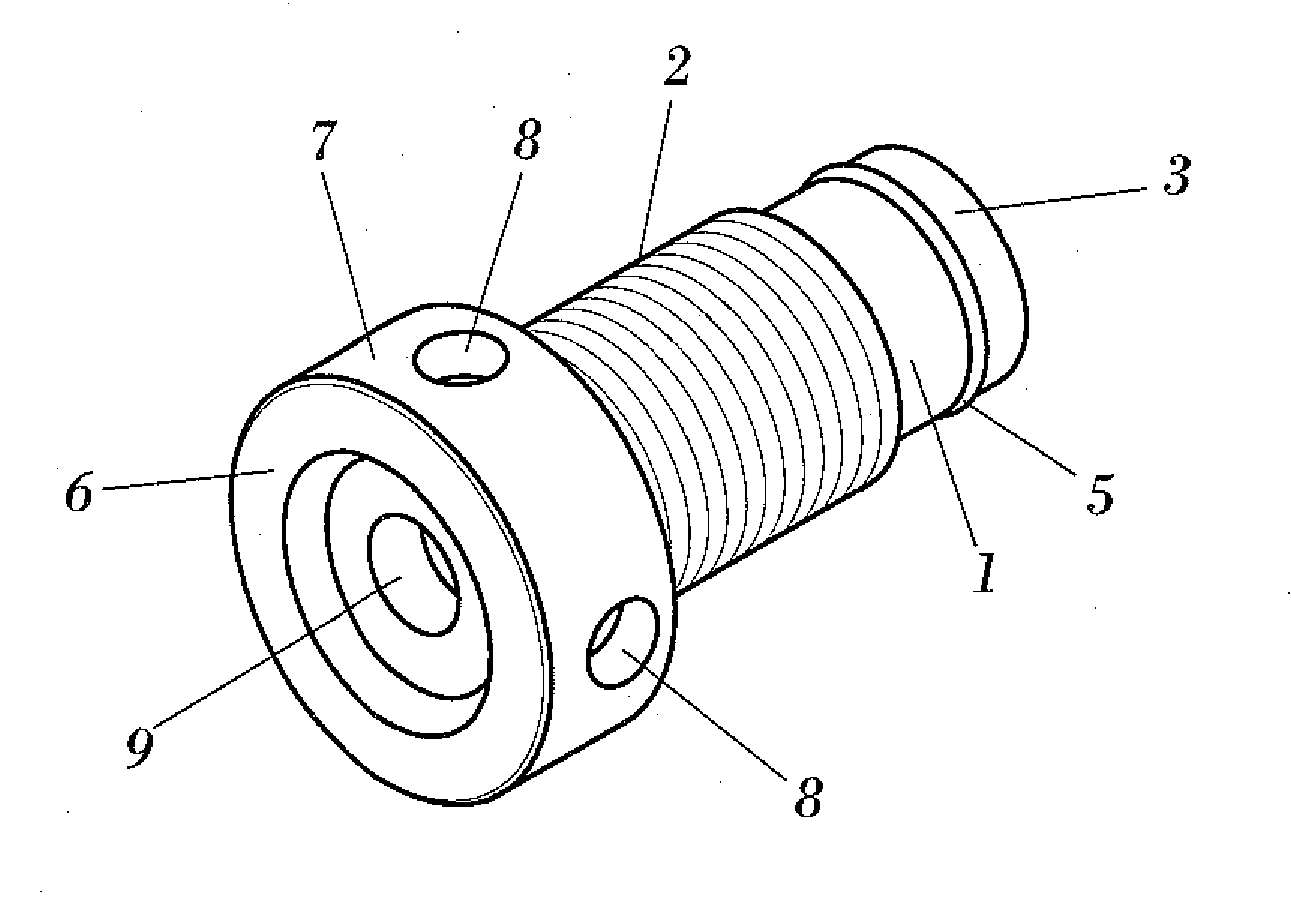

Quick-assembly breech plug for muzzleloader firearms

a breech plug and firearm technology, applied in the field of quick-assembly breech plugs for muzzleloader firearms, can solve the problems of complex and expensive manufacture of such plugs, and it is extremely difficult to prevent the gas from escaping through said clearances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

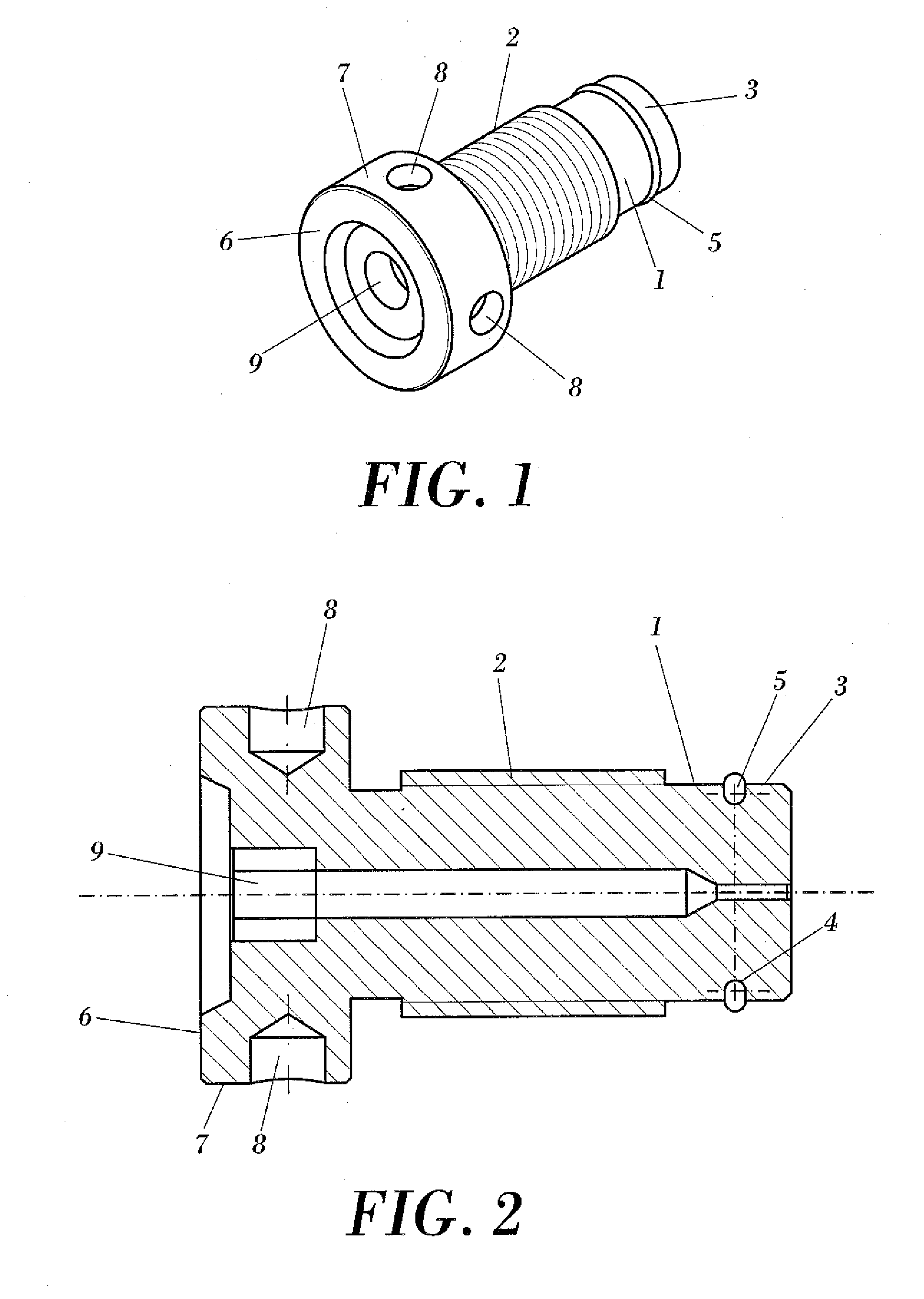

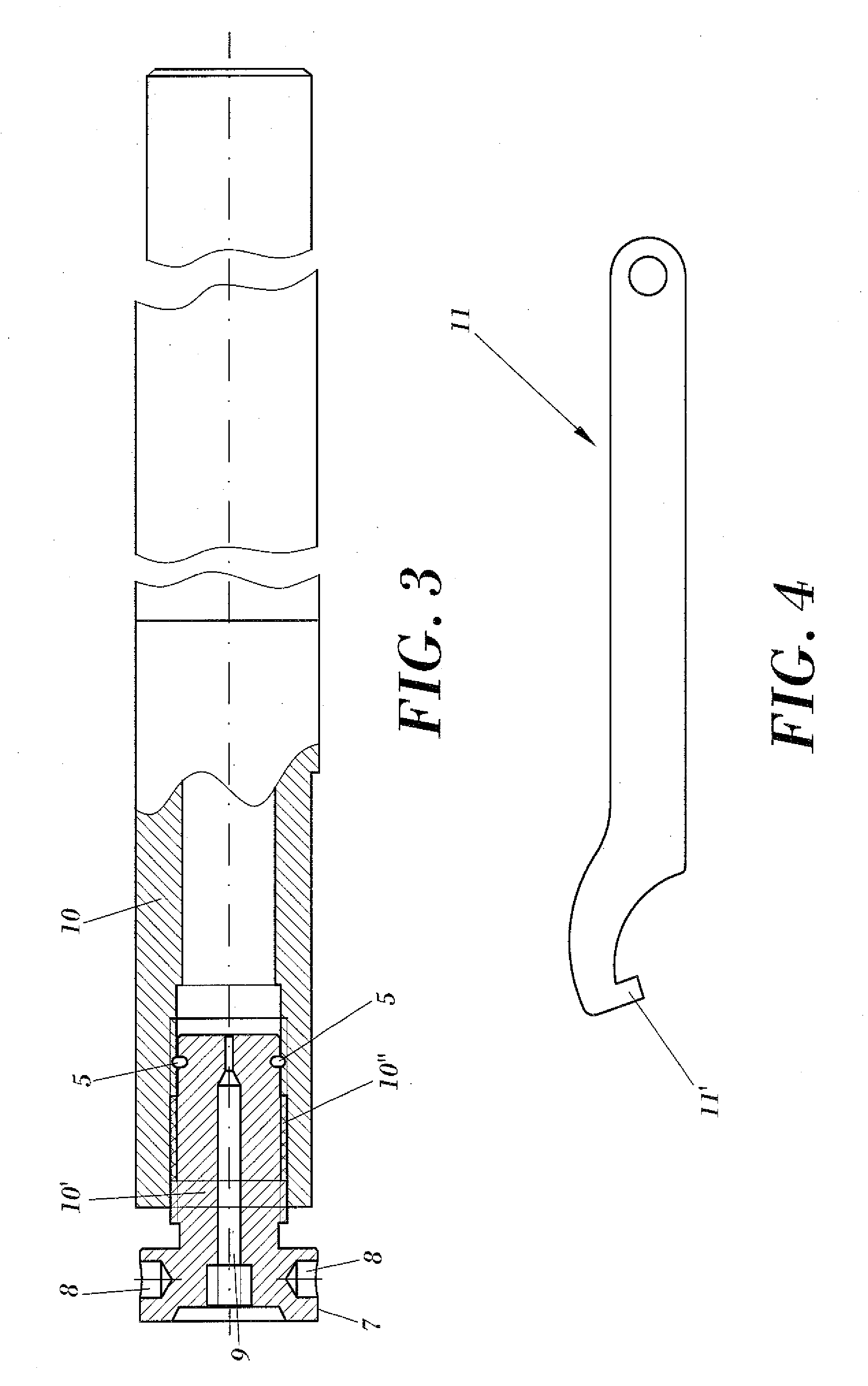

[0007]The present invention relates to a quick-assembly breech plug for muzzleloader firearms, which allows both assembling and disassembling the breech plug in the barrel in an extremely quick and effective manner, for the purpose of removing the breech plug to clean the loader or to remove a charge housed in the barrel. Said quickness and effectiveness are based on the breech plug of the invention requiring for its assembly and / or disassembly a smaller number of rotations in comparison with the currently existing breech plugs, the thread of which has a single start. The breech plug of the invention is simple, practical and inexpensive to manufacture, not requiring complex means for coupling to the barrel, as in the case of bayonet-type couplings, and allowing its introduction from any angular position, without having to be in a certain angular position for its introduction.

[0008]The quick-assembly breech plug for muzzleloader firearms proposed by the invention comprises a cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com