Chinstrap assembly

a chinstrap and assembly technology, applied in the direction of headwear fastening, protective garments, helmets, etc., can solve the problems of not being particularly comfortable to wear for a prolonged period, helmets equipped with conventional chinstrap assemblies, helmets that cannot be fitted ergonomically to the head using those straps, etc., and achieve the effect of high drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

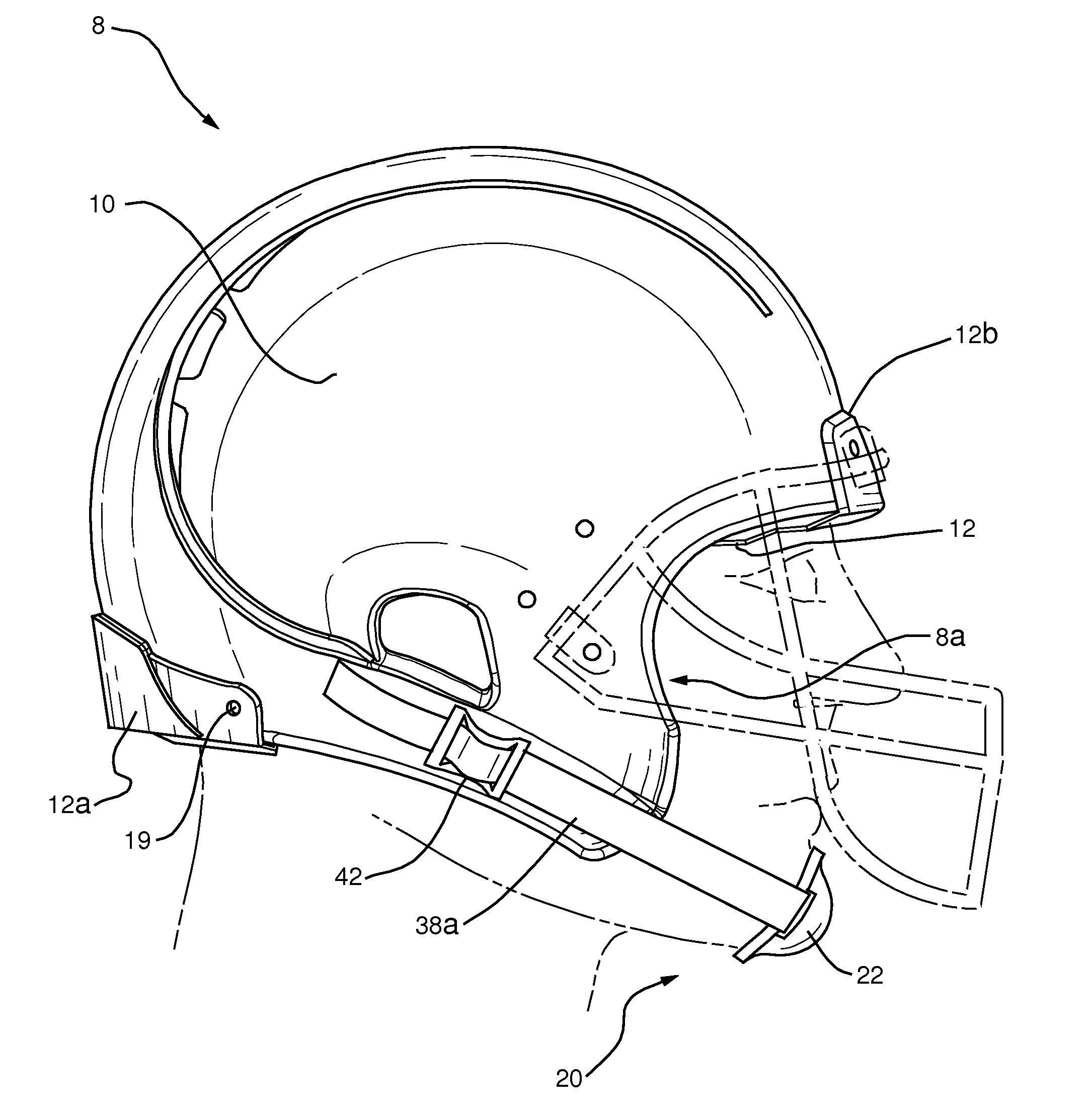

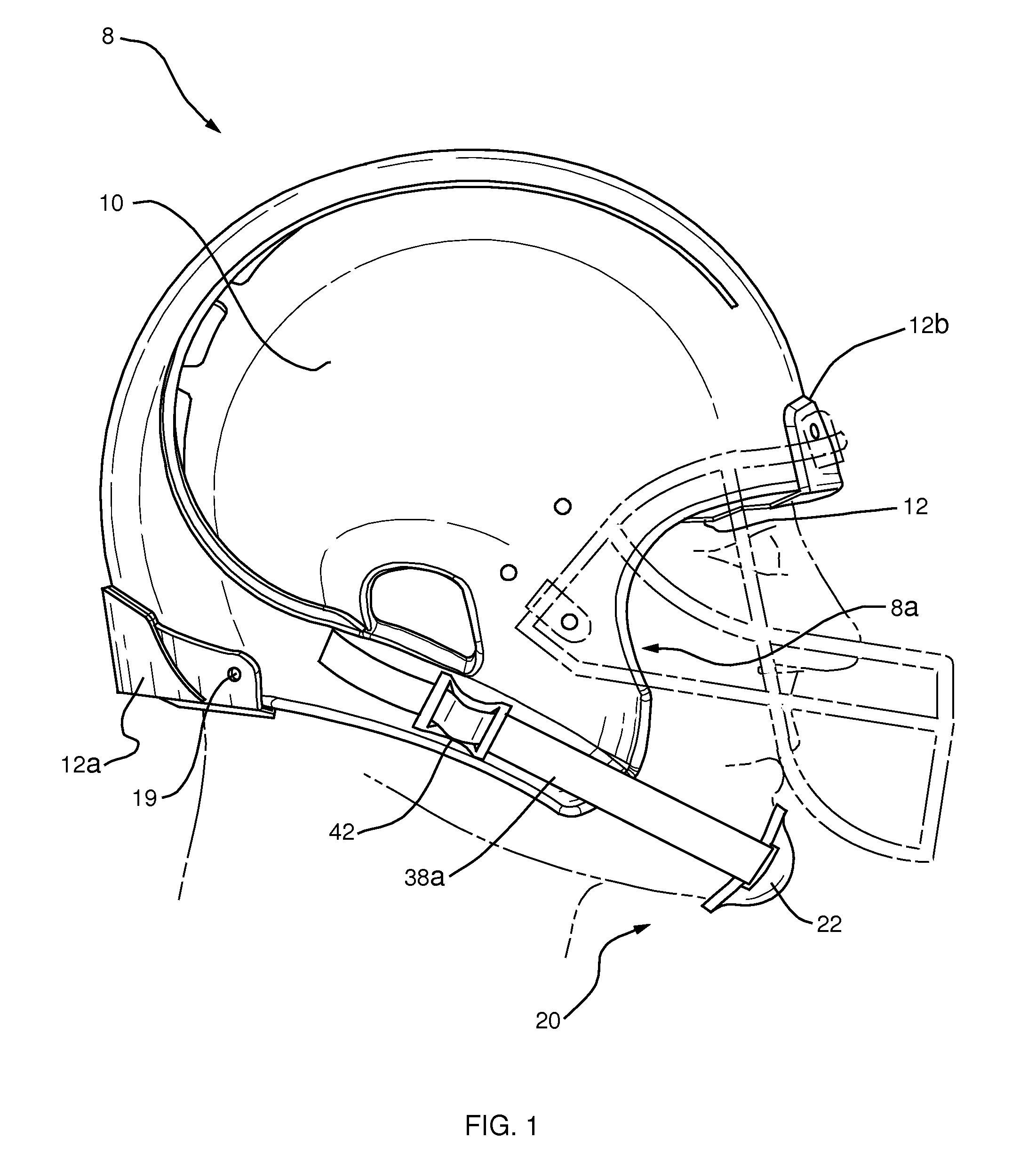

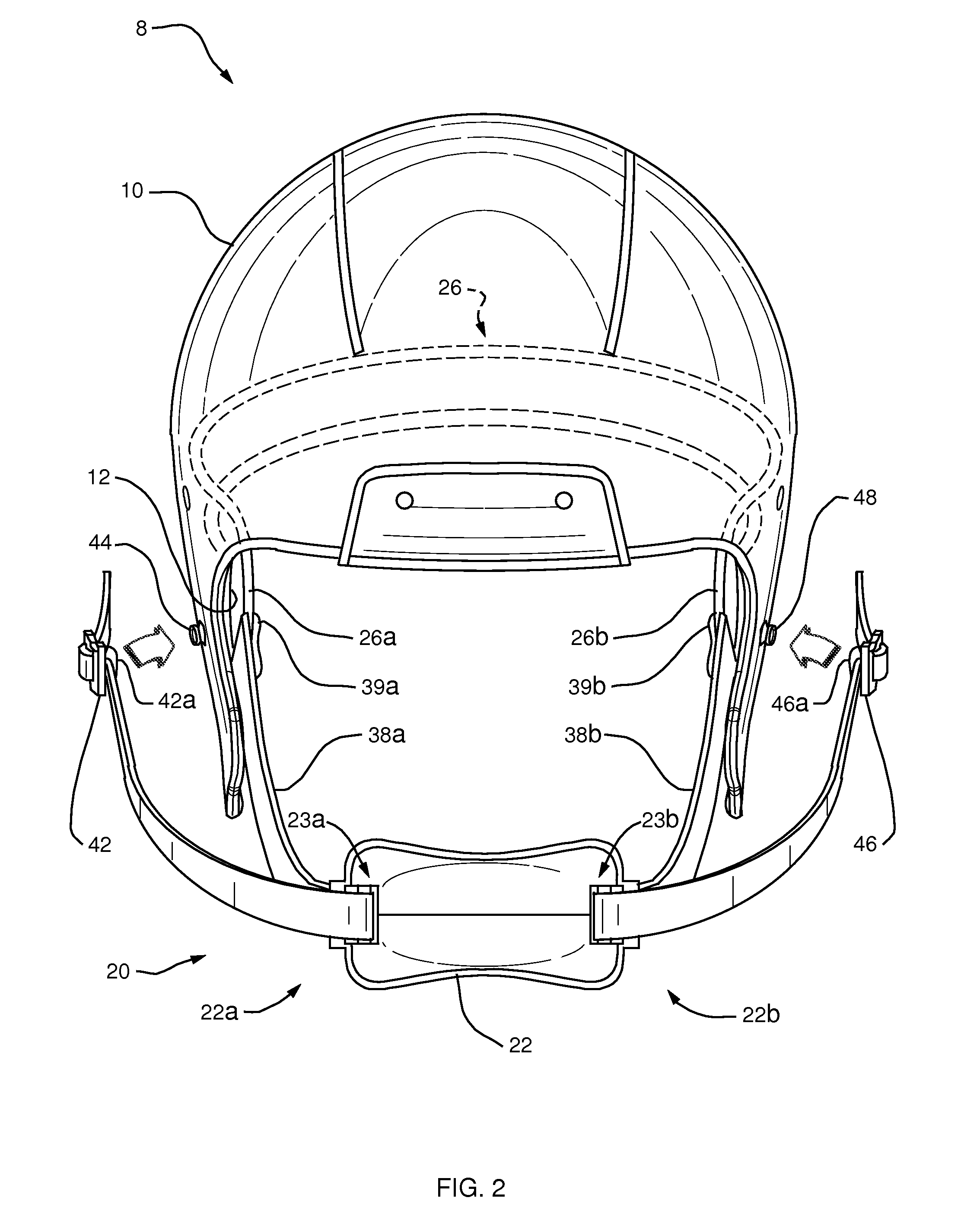

[0030]Referring to FIGS. 1 and 2 of the drawings, shown there is a helmet 8 having a semi-rigid outer layer 10 which may be a relatively hard plastic shell that deforms locally and radially in response to an impact, and an inner layer 12 which may be of a softer, less rigid material.

[0031]The helmet 8 preferably also includes a third, middle, layer between the outer and inner layers 10 and 12 and which comprises a plurality of compressible cells (not shown) which extend between the inner and outer layers, as well as a dynamic inner liner composed of a plurality of resilient pads or capsules (not shown) which are connected to the cells and project from the interior surface of the inner layer 12. In the illustrated helmet, the inner layer 12 is a flexible, molded plastic structure which includes a rear flange 12a which extends up around the outside of shell 10 and is secured thereto by fasteners 19. A comparable flange 12b at the front of layer 12 is similarly fastened to the shell 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com