Use of soy kefir powder for reducing pain, blood pressure and inflammation

a technology of soy kefir and kefir powder, which is applied in the field of kefir, can solve the problems of not showing strong results in pain relief, one cannot predict if a derived soymilk product would have a significant effect on pain relief and treatment or reduction, and the recent human trial involving soy intake did not show strong results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Soy Kefir Powder According to a Preferred Method of the Invention

[0097]Hundred (100) cases of sterile (UHT) SO NICE Natural soymilk (Soyaworld Inc.), each case consisting of twelve 946 mL Tetrapaks, were obtained (three production lots). Soymilk was stored at 4° C. in a walk-in cold room.

[0098]A 150 L Chemap fermentor was used for all production fermentations.

[0099]Prior to the first fermentation, the fermentor was cleaned using standard protocols known to one skilled in the art and then steam sterilized at 121° C. using a computer controlled sterilization cycle. The fermentor was equipped for on-line control of temperature and continuous monitoring of pH. The fermentations were run without air addition (anaerobic) and without agitation, except for brief periods during startup and harvesting.

[0100]The fermentation substrate consisted of soymilk and dextrose. Except for batches designated K0830A and K0830B, each batch used 9 cases of milk (102 L) plus 2 kg of dextrose....

example 2

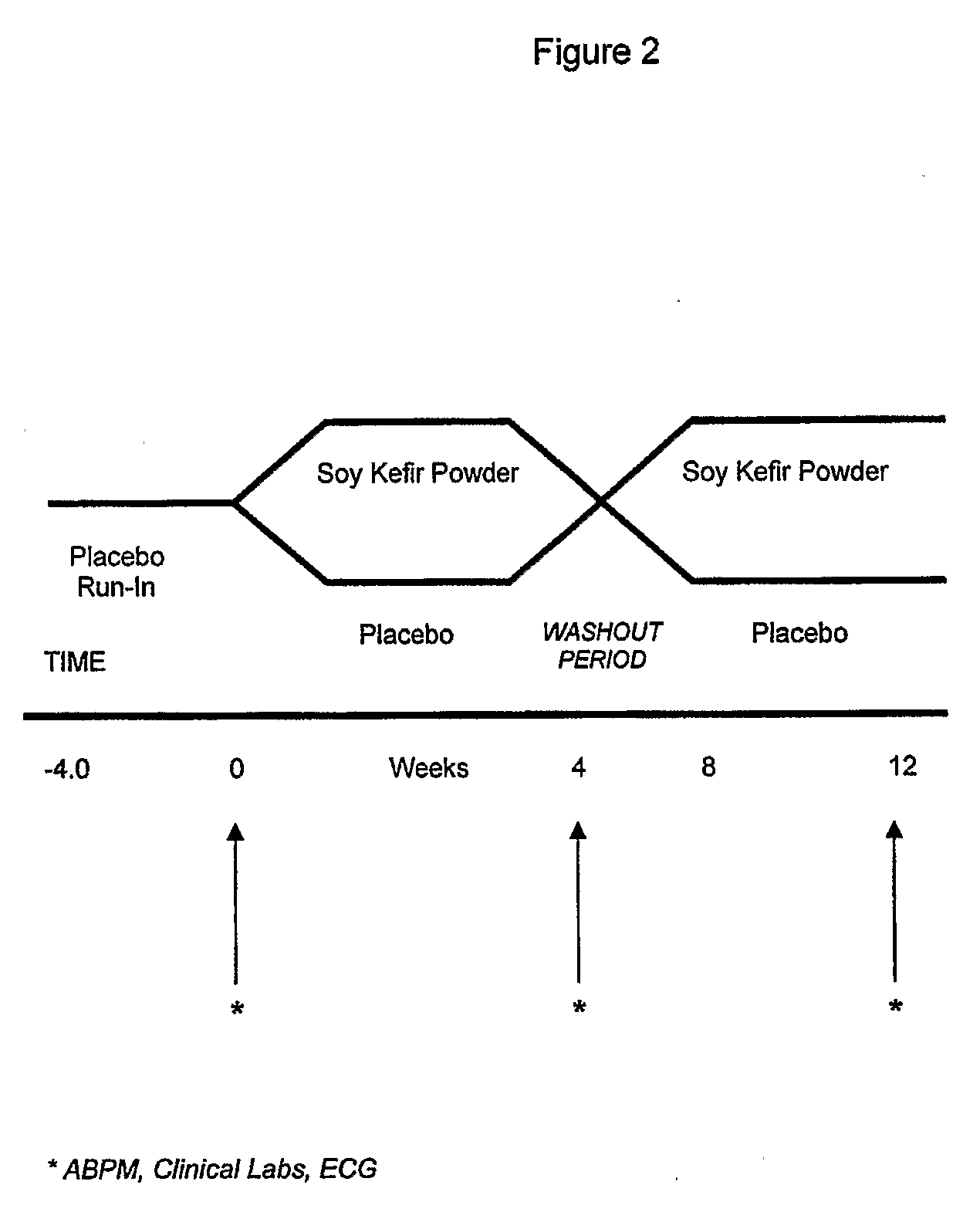

Use of the Soy Kefir Powder of the Invention for Reducing Pain, Blood Pressure and Inflammation

Raw Materials Used in Manufacturing

Source of Soymilk

[0108]Soyaworld Inc., Burnaby, BC, Canada.

Source of Kefir Grains

[0109]The All-Russia Dairy Institute (ARDI), 35 Lyusinovskaya Street, Moscow, Russia.

[0110]Fermentation was done as described in Example 1.

[0111]As kefir grains increase in volume during fermentation, a portion of grains are removed to maintain constant grain-to-milk ratio. When fermentation is completed, grains are removed by coarse sieving and used as the inoculum for fermenting a subsequent batch of soymilk.5 Alternatively, grains can be lyophilized for long-term storage.1

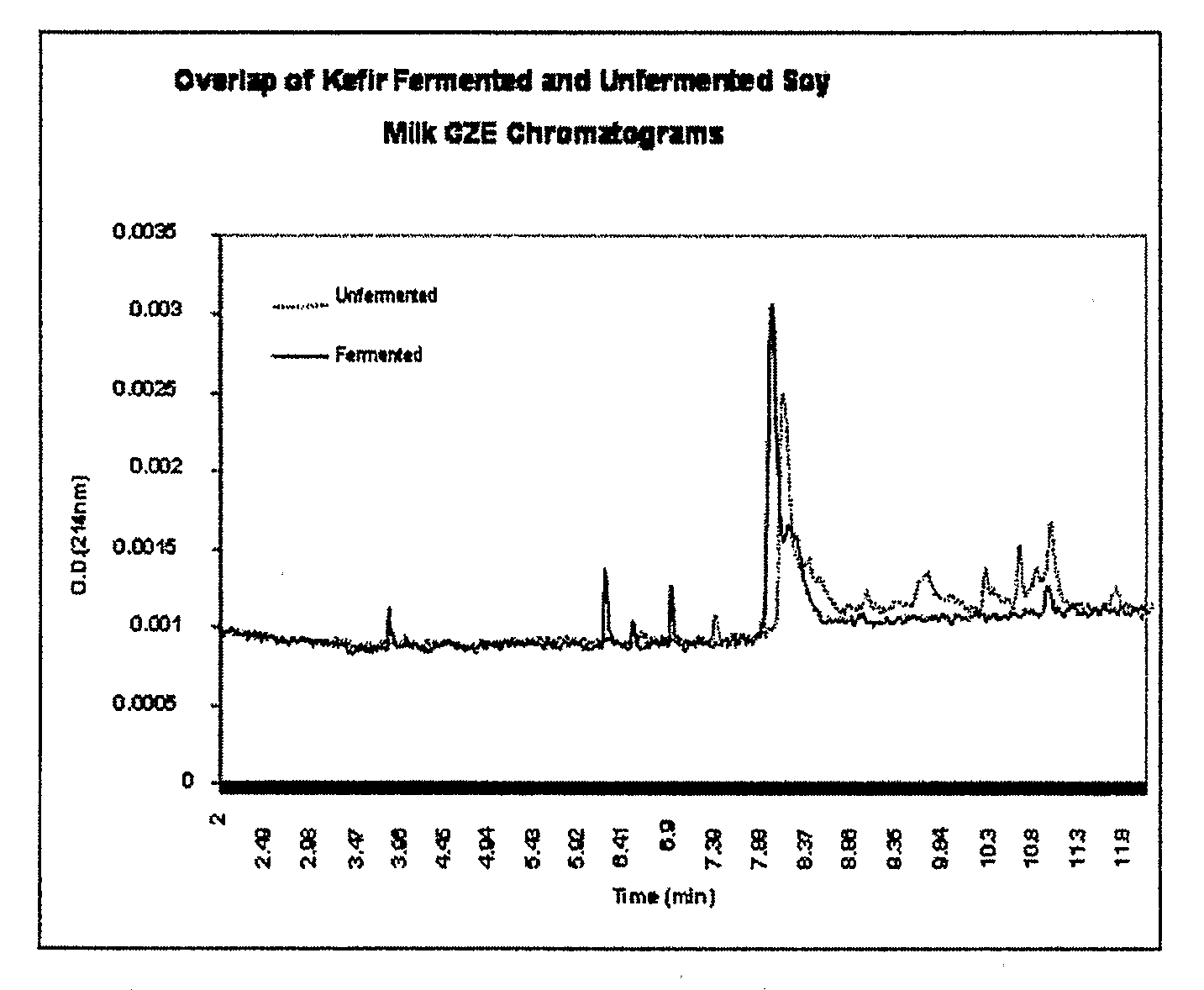

[0112]Following removal of the grains, liquid kefir is approximately 8% total solids. It is then converted to powder by spray-drying, thus removing any significant amount of alcohol.

[0113]There are no significant variations of vitamin and mineral content following kefir ferment...

example 3

Use of the Soy Kefir Powder of the Invention for Relieving Pain

[0122]Case Study Trials with Soy Kefir Powder of the Invention Related to Pain Relief

[0123]Overall, 14 human volunteers have consumed soy kefir powder of the present invention (up to 35 g / day). They experienced no significant adverse events. The human volunteers followed no specific diets. The subjects received 35 g of the soy kefir powder of the present invention every day. The soy kefir power was taken by the subjects once a day for periods ranging from 2 to 4 weeks. The soy kefir powder of the present invention was used in a liquid vehicle such as water or juice (around 200 ml) or in a dry vehicle such as cereals. The volunteers also answered a questionnaire daily on the following symptoms: cough, phlegm, joint pain, digestive disturbance, fatigue, stress, depression, bowel irregularity, sleep disturbances and agitation. The answers of the volunteers were collected starting three days before the starting point of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com