Package handle

a packaging handle and handle technology, applied in the field of flexible packaging, can solve the problem of relative easy to punch or cut defined apertures in packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]A purpose of the present invention is to allow for a package, such as a flexible package, to be carried or otherwise manipulated with a handle punched or cut into a portion of the package. The various embodiments and teachings provided herein can also be employed with a rigid or semi-rigid package.

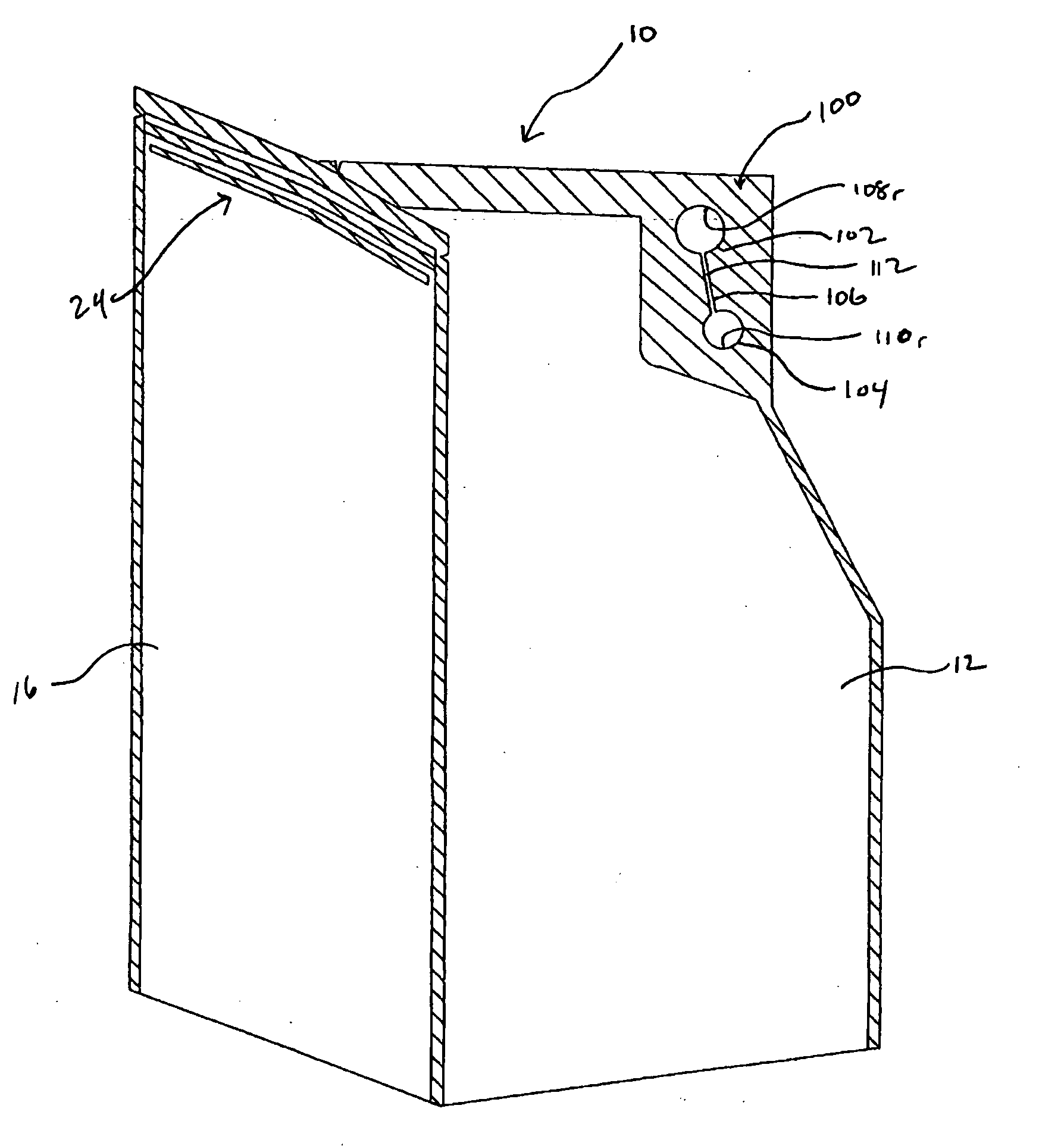

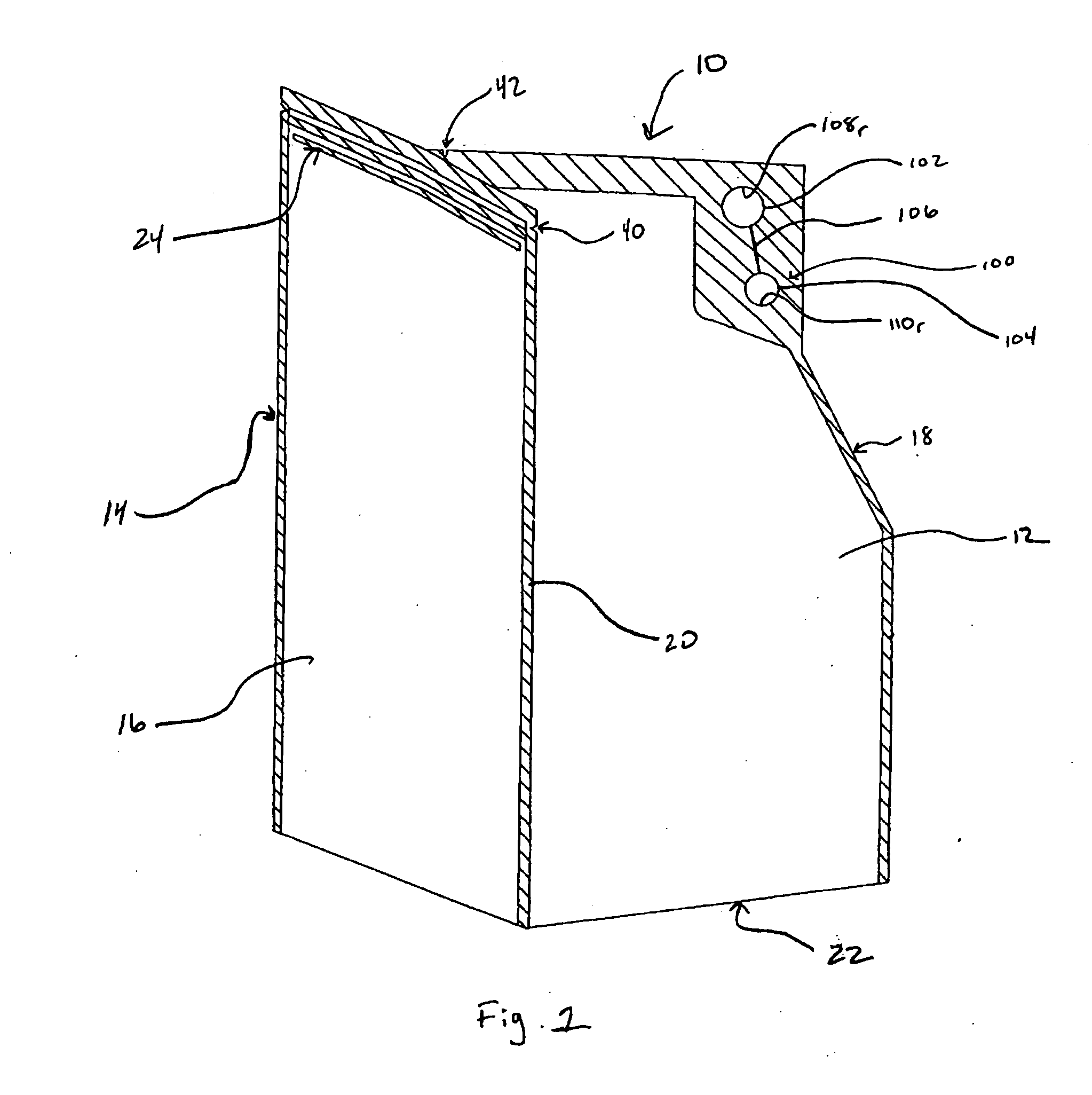

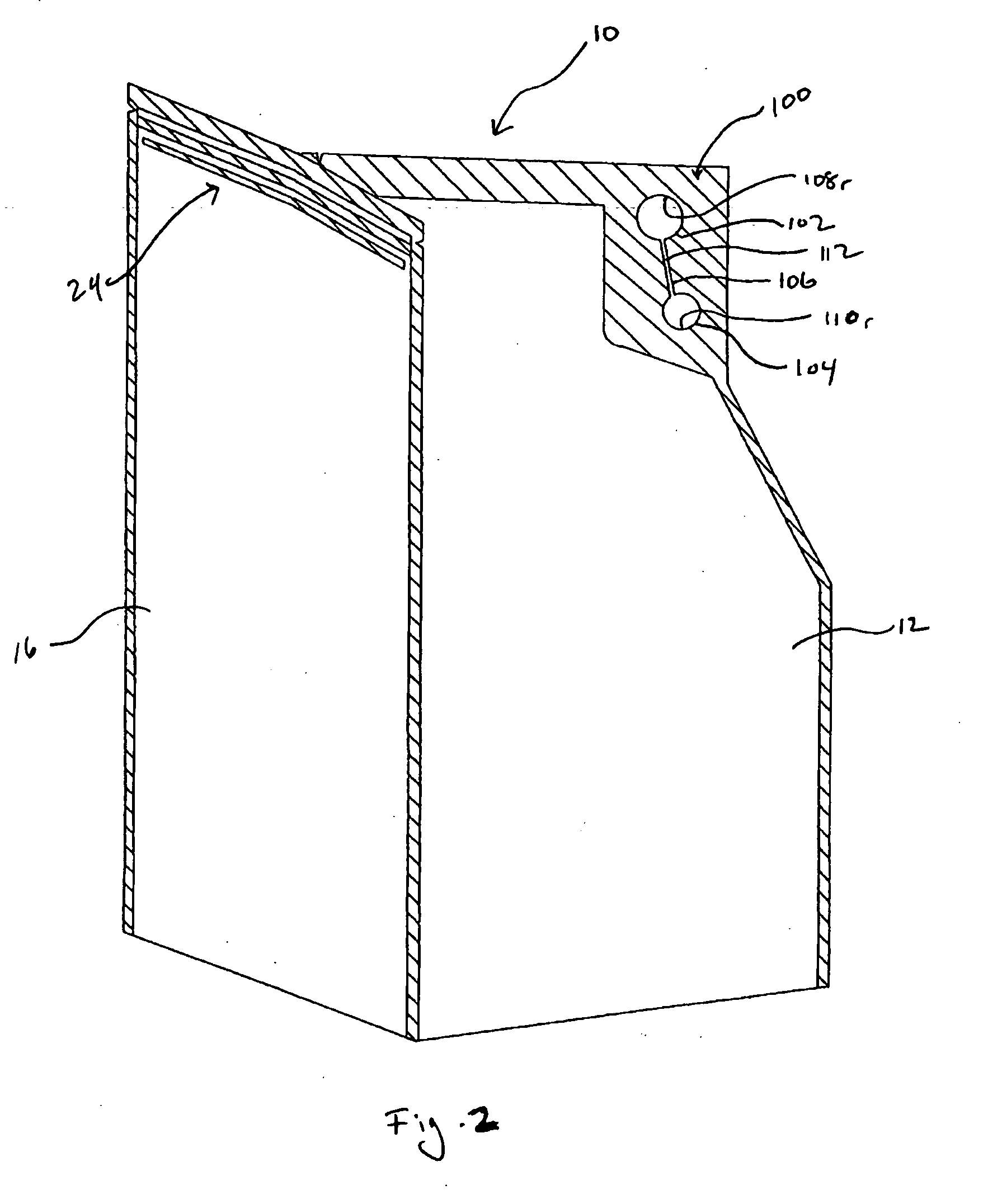

[0037]Referring to FIGS. 1-3, a flexible package 10 and components and configurations in accordance with embodiments of the present invention are shown. The package 10 generally includes a front panel portion 12, a back panel portion 14, and could include an access device 24. In addition, the package 10 can include side panels 16, 18, a top panel portion 20, and a bottom panel portion 22. In the depicted embodiments, the joining and / or shaping of the above-referenced panels define the package 10 with an internal cavity 25, generally having an adjustable internal volume capacity. The panels 12-22 are often referred to as “webs” or films. Each panel can be formed from an individual web...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com