Fuels for Homogeneous Charge Compression Ignition Combustion Engine

a technology of homogeneous charge and combustion engine, which is applied in the direction of fuels, liquid carbonaceous fuels, petroleum industry, etc., can solve the problems of engine operation restrictions, and achieve the effects of enhancing engine output, quiet engine combustion, and lowering the maximum pressure rise ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0075](Engine Operation Conditions)

[0076]The engine was operated at an engine speed of 1000 rpm, an absolute boost pressure of 155 kPa and an intake manifold temperature of 58° C. The experiment described below was carried out for each fuel under the same engine conditions such as compression ratio, engine speed, boost pressure, intake manifold temperature, air flow rate, intake-exhaust valve timing and EGR rate except that the fuel injection quantity was varied.

[0077](Fuels)

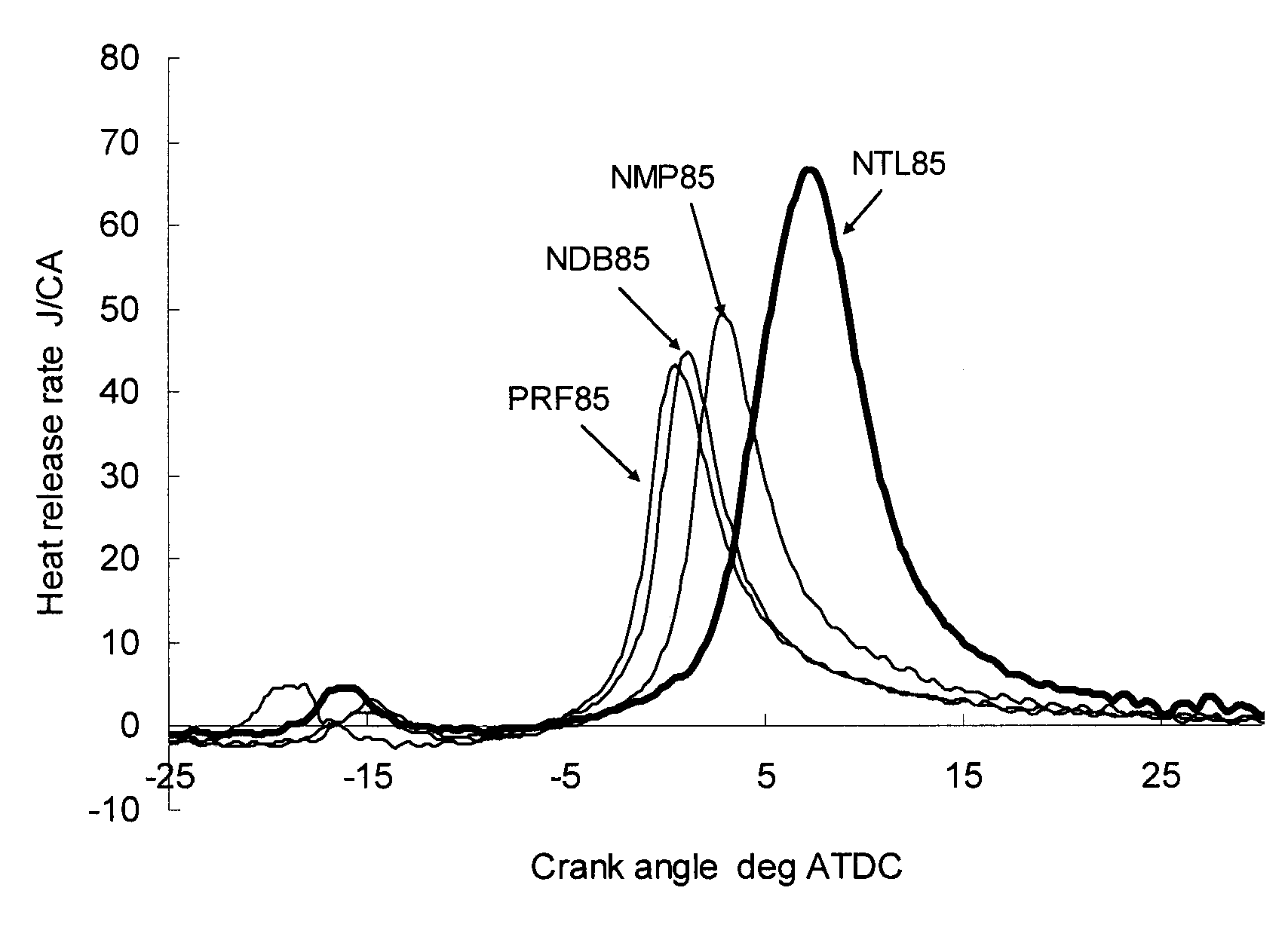

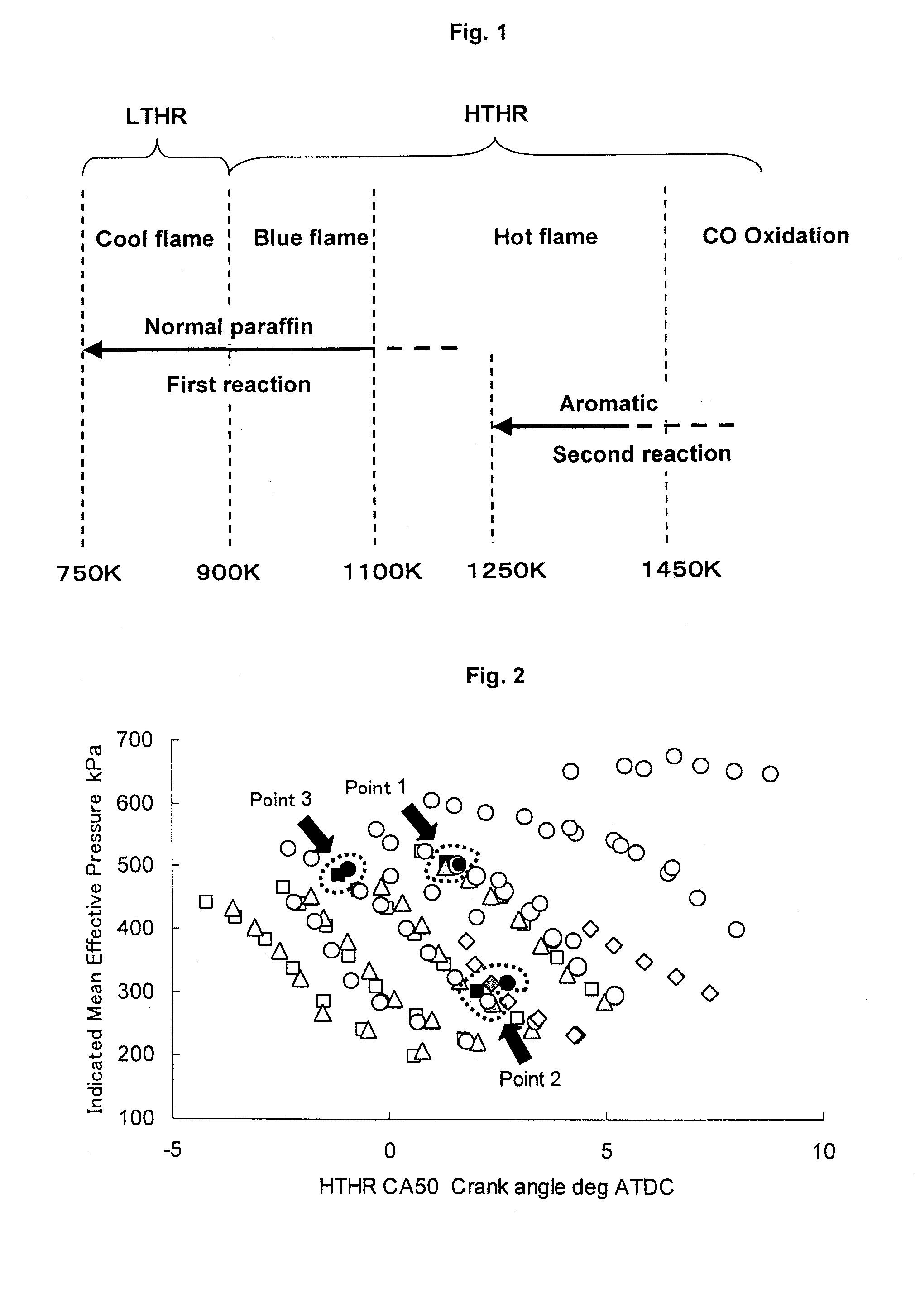

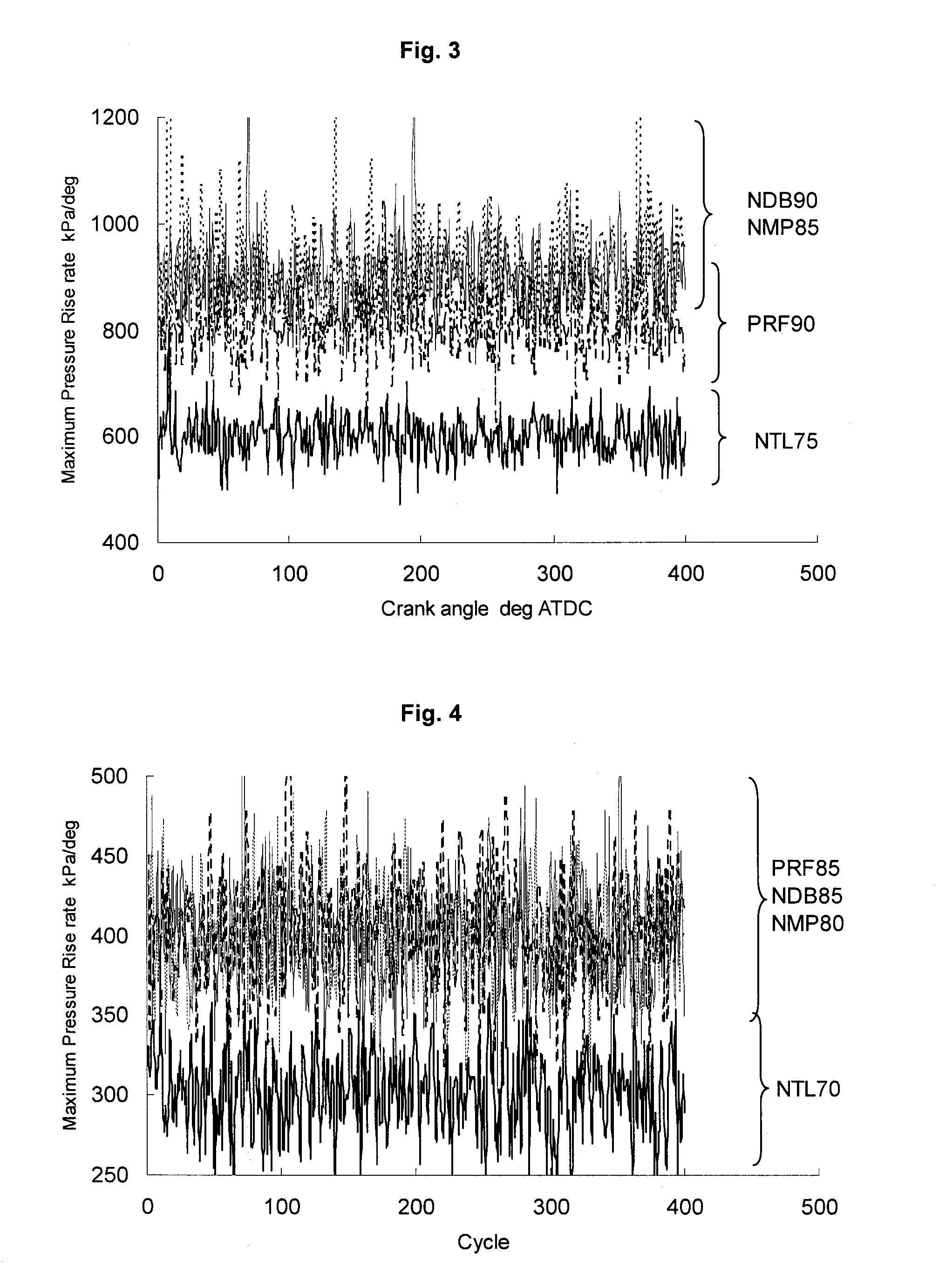

[0078]FIG. 2 shows the chart of 400 cycle averaged crank angle of 50% burn of high temperature heat release (HTHR CA50) and indicated mean effective pressure (IMEP) obtained by driving the engine using various fuels. Where fuels with the substantially same IMEP and HTHR gathered were selected as Points 1, 2 and 3, and the change in maximum pressure rise rate over 400 cycles in each of the points were measured (the detail of this experiment should be referred to “SAE2008-01-0007” published in April, 2008).

[0079]F...

example 2

[0081](Fuel)

[0082]The following fuels with the same research octane number were prepared (when the difference in the research octane number between PRF series fuels and NTL series fuels measured on a CFR (Cooperative Fuel Research) engine in accordance with JIS K 2280 is within 3, it was regarded as inaccuracy).

[0083](1) Fuels with a research octane number of 75

Comparative Examples

PRF75, NDB75, NMP75, NCP75

Example NTL75

[0084](2) Fuels with a research octane number of 80

Comparative Examples

PRF80, NDB80, NMP80, NCP80

Example NTL80

[0085](3) Fuels with a research octane number of 85

PUM

| Property | Measurement | Unit |

|---|---|---|

| octane number | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com