Recyclable and compostable eating utensils and other products made from crop-based resin & method of manufacture

a technology of crop-based resin and eating utensils, which is applied in sustainable manufacturing/processing, packaging foodstuffs, tableware, etc., can solve the problems of reducing the rigidity of products made from resins that are biodegradable frequently, unable to convert into compost, and ordinarily not biodegradable petroleum-based plastic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

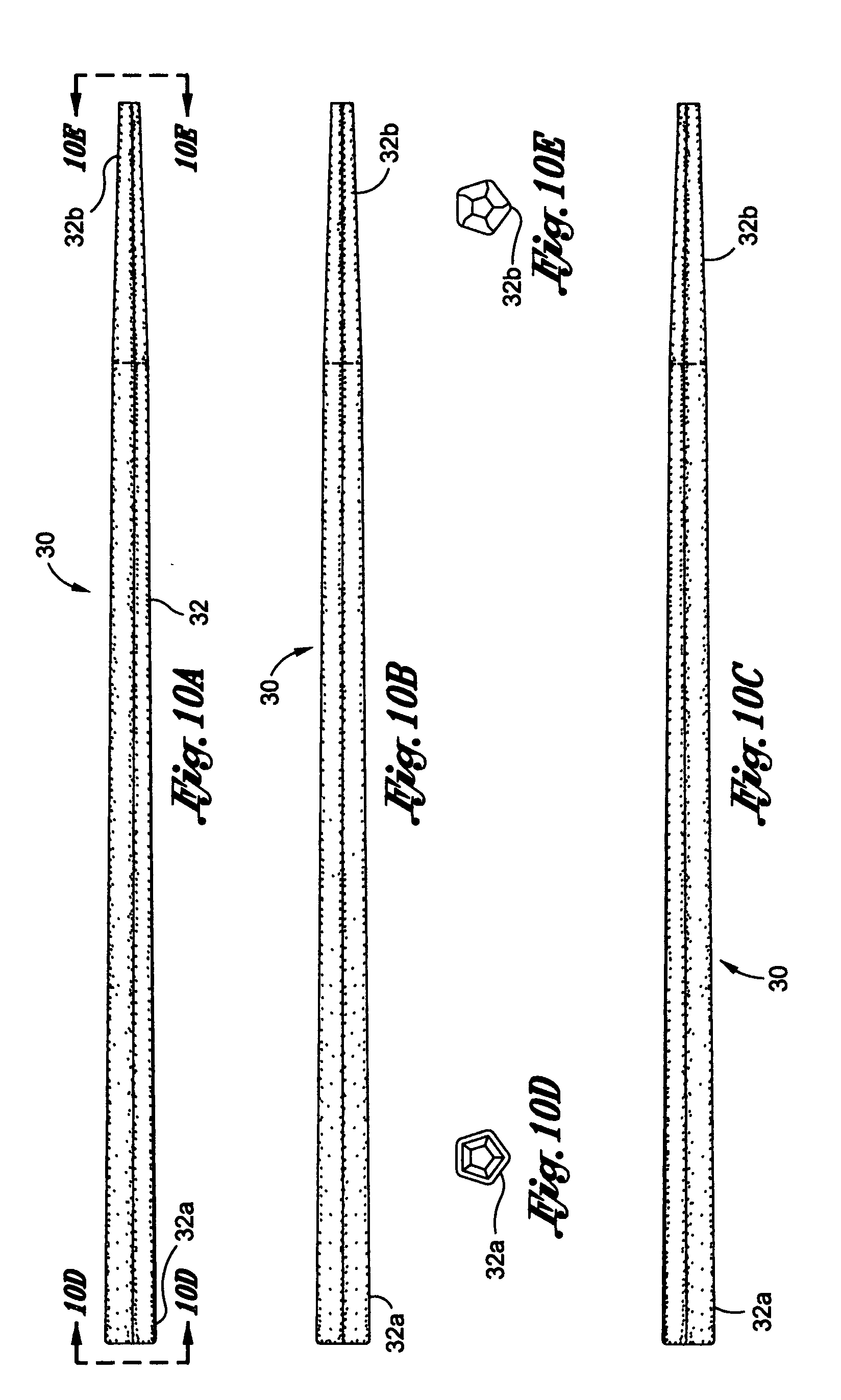

[0038]FIGS. 10A through 10E show the chopstick of this invention where:

[0039]FIG. 10A is a top plan view of the chopstick;

[0040]FIG. 10B is a side view of the chopstick;

[0041]FIG. 10C is a bottom plan view of the chopstick;

[0042]FIG. 10D is an end view of the chopstick taken along line 10D-10D of FIG. 10A; and

[0043]FIG. 10E is an end view of the chopstick taken along line 10E-10E of FIG. 10A.

fourth embodiment

[0044]FIGS. 11A through 11E show the chopstick of this invention where:

[0045]FIG. 11A is a top plan view of the chopstick;

[0046]FIG. 11B is a side view of the chopstick;

[0047]FIG. 11C is a bottom plan view of the chopstick;

[0048]FIG. 11D is an end view of the chopstick taken along line 11D-11D of FIG. 11A; and

[0049]FIG. 11E is an end view of the chopstick taken along line 11E-11E of FIG. 11A;

[0050]FIG. 12 shows a knife of this invention wherein (a) is a perspective view, (b) is a side edge view, and (c) is a top view.

[0051]FIG. 13 shows a fork of this invention wherein (a) is a perspective view, (b) is a side edge view, and (c) is a top view.

[0052]FIG. 14 shows a spoon of this invention wherein (a) is a perspective view, (b) is a side edge view, and (c) is a top view.

[0053]FIG. 15 shows a spork of this invention wherein (a) is a perspective view, (b) is a side edge view, and (c) is a top view.

fifth embodiment

[0054]FIGS. 16A through 16E show the chopstick of this invention having six sides where:

[0055]FIG. 16A is a perspective view of the six-sided chopstick of this invention looking at the rear end of the chopstick.

[0056]FIG. 16B is a perspective view of the six-sided chopstick of this invention looking at the front end of the chopstick.

[0057]FIG. 16C is a top view of the six-sided chopstick of this invention.

[0058]FIG. 16D is a side view of the six-sided chopstick of this invention.

[0059]FIG. 16E is a rear view of the six-sided chopstick of this invention.

[0060]FIG. 16F is a front view of the six-sided chopstick of this invention.

[0061]FIGS. 17A and 17B depict another embodiment of the six-sided chopstick of this invention differing from the embodiment shown in FIGS. 16A through 16D in length where:

[0062]FIG. 17A is a top view of the six-sided chopstick of this invention.

[0063]FIG. 17B is a side view of six-sided chopstick of this invention.

[0064]FIG. 18 is a perspective view of a dog ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com