Cigar cutting apparatus

a cutting device and cigar technology, applied in cigar manufacture, tobacco, food science, etc., can solve the problems of high cost and complicated manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

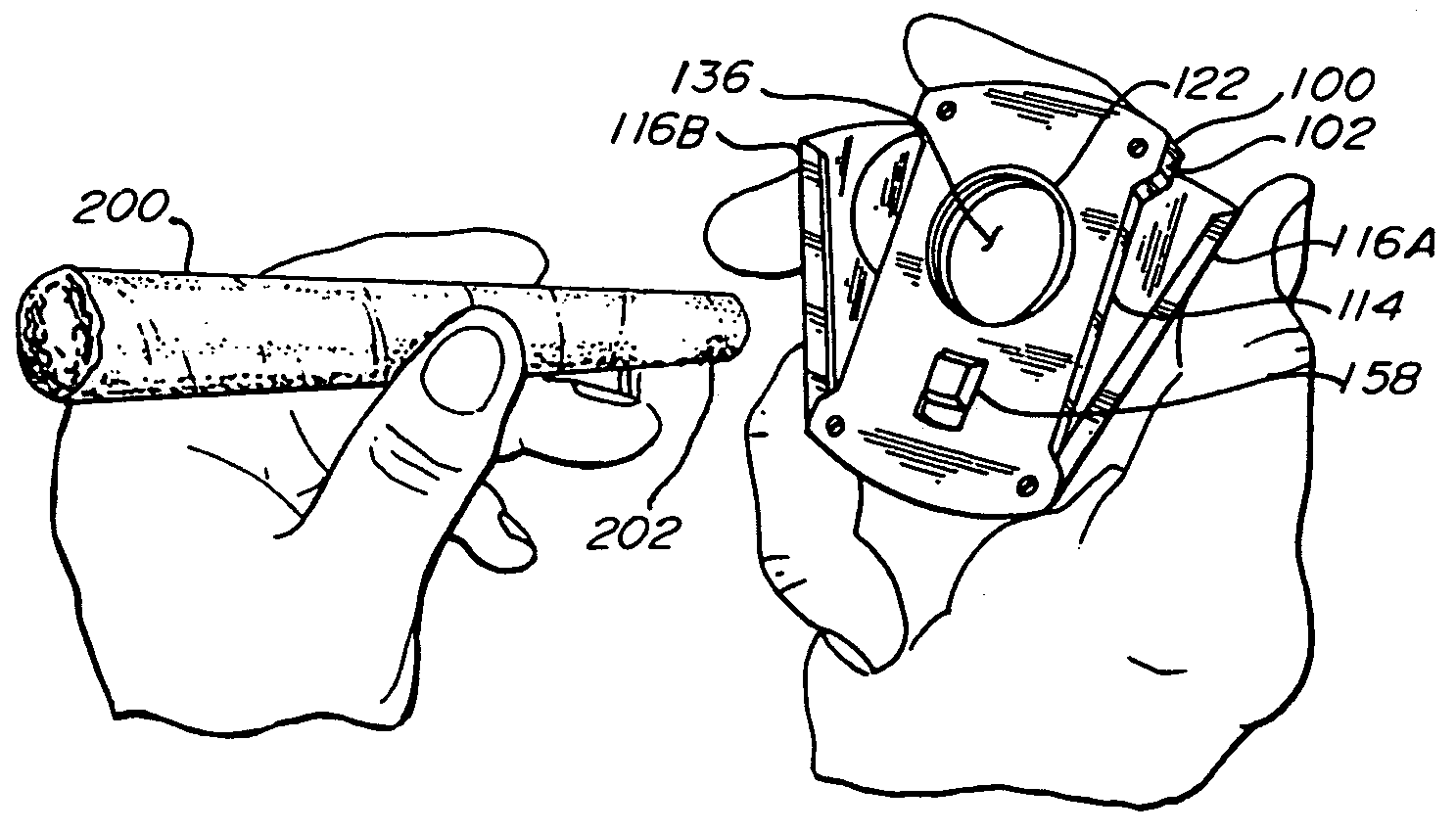

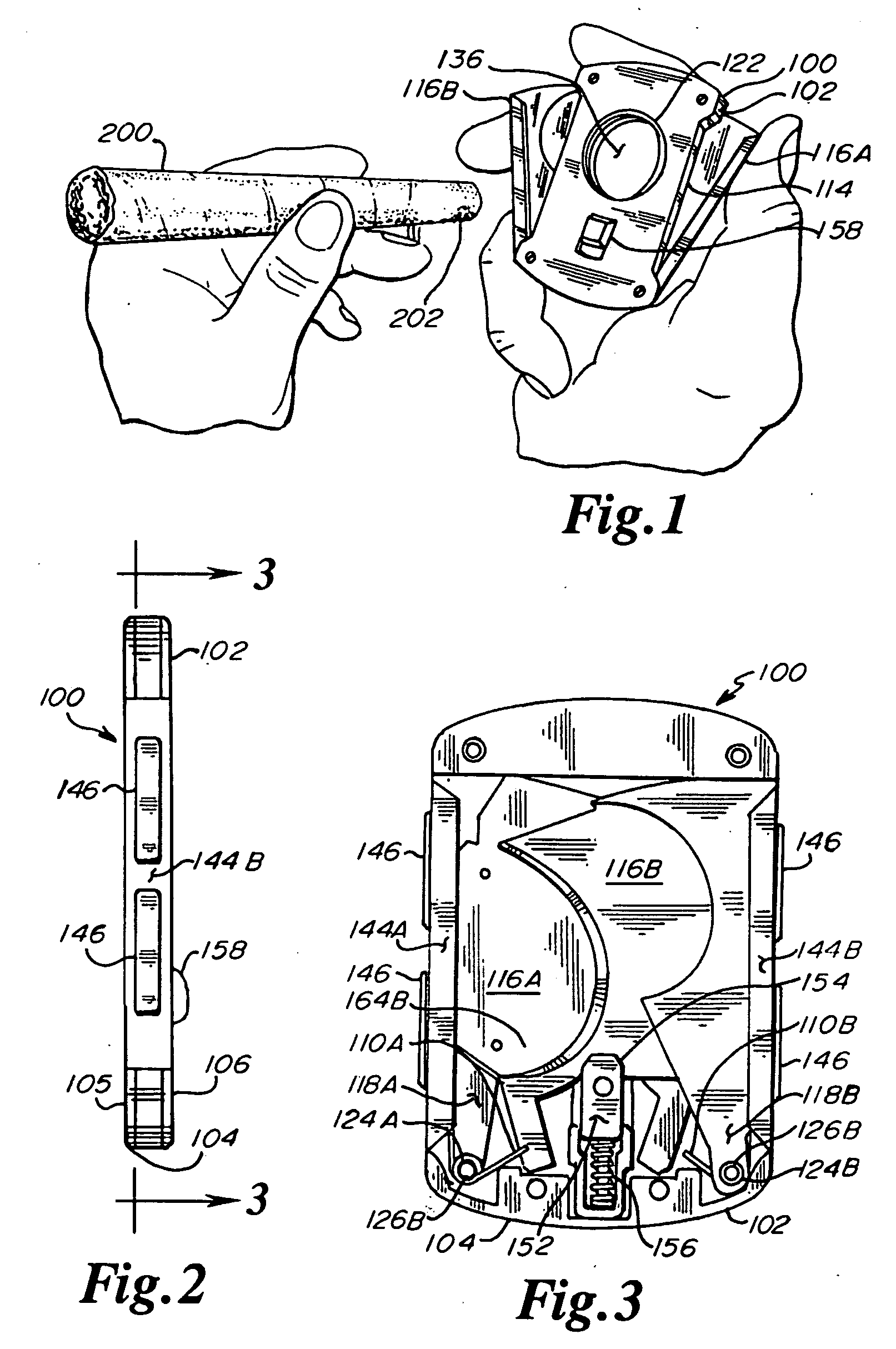

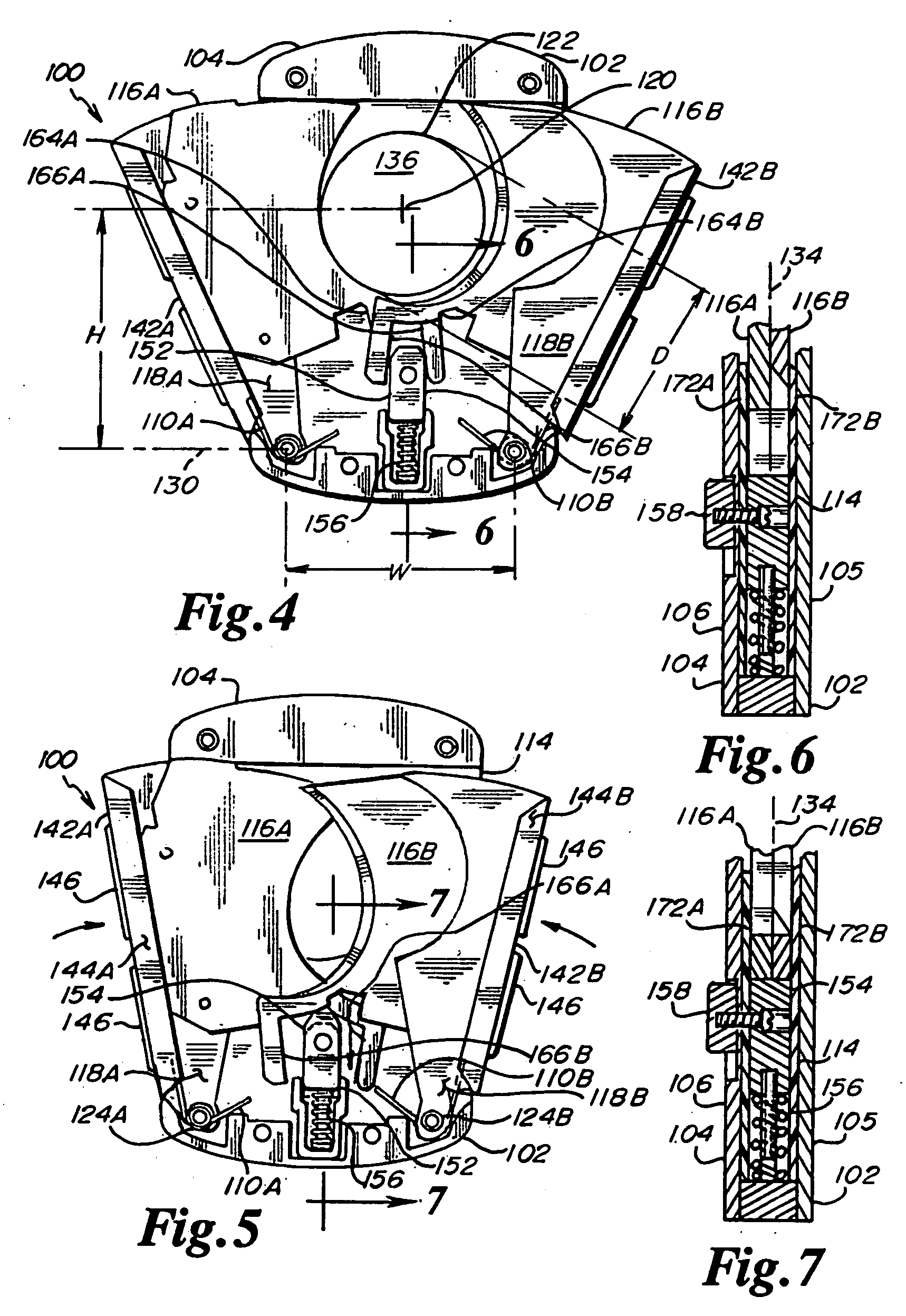

[0036]Reference is now made to FIGS. 1 through 8, where there is shown an exemplary cigar cutter 100 according to just one of the infinite number of possible cigar cutters within the scope of the invention.

[0037]Cutter 100 has a housing 102 formed of base 104 and rear plate 105. Base 104 includes front plate 106, top frame 108 and bottom frame 112. The front plate is permanently affixed to or may be integrally formed with the top and bottom frames to form the base, and the rear plate is screwed to the top and bottom frames, and thereby to the base, to form the housing.

[0038]The plates and frames of the housing form and surround a generally rectangular internal slot 114 which traverses the housing from side to side, open at both sides, and contains front cutting blade 116A and rear cutting blade 116B, which may be identical to and positionally reversed from each other. A circular hole 122 passes through the two plates of the housing perpendicular to slot 114 and has a diameter D that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com