Tire sealant dispensing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

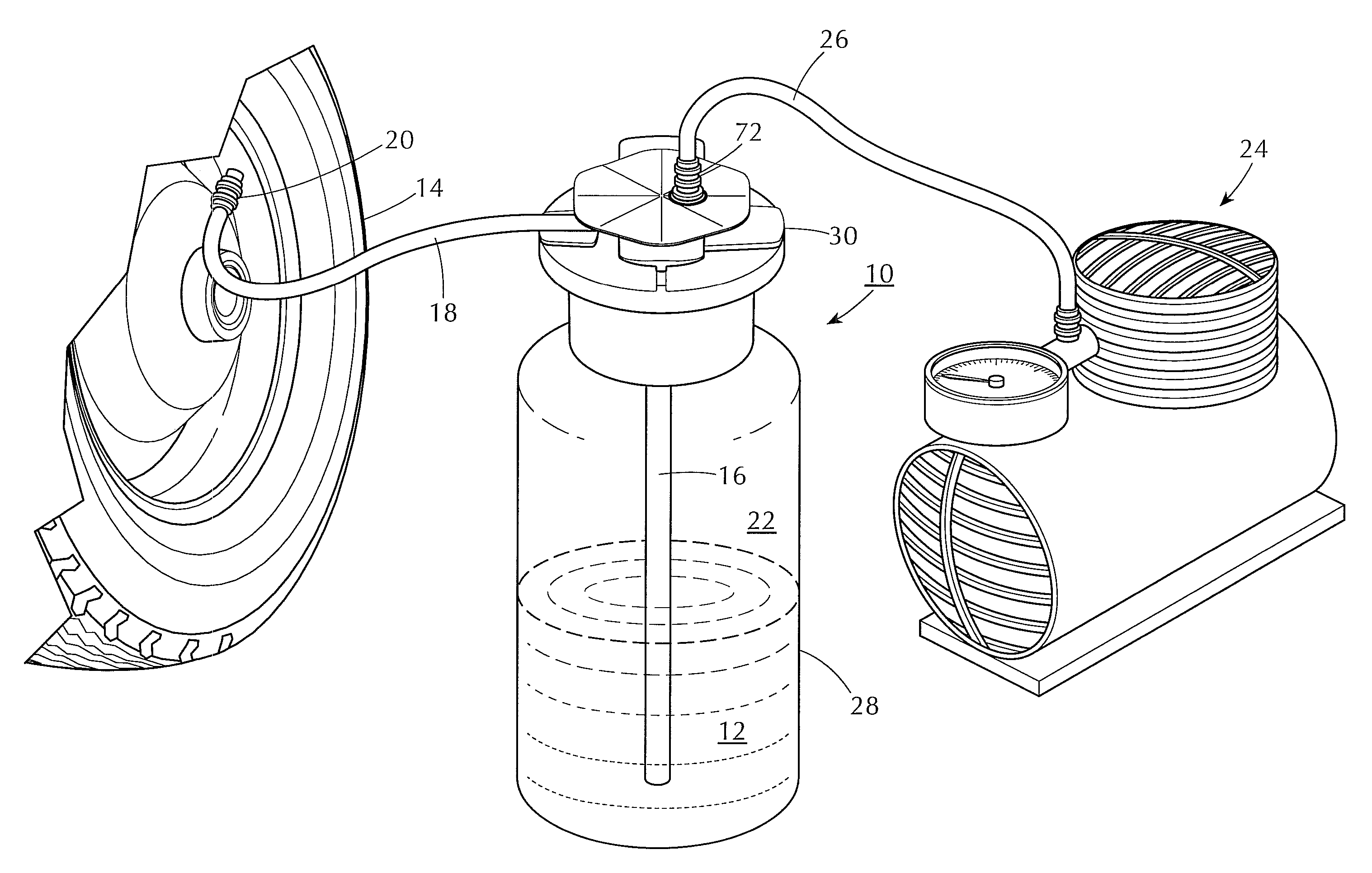

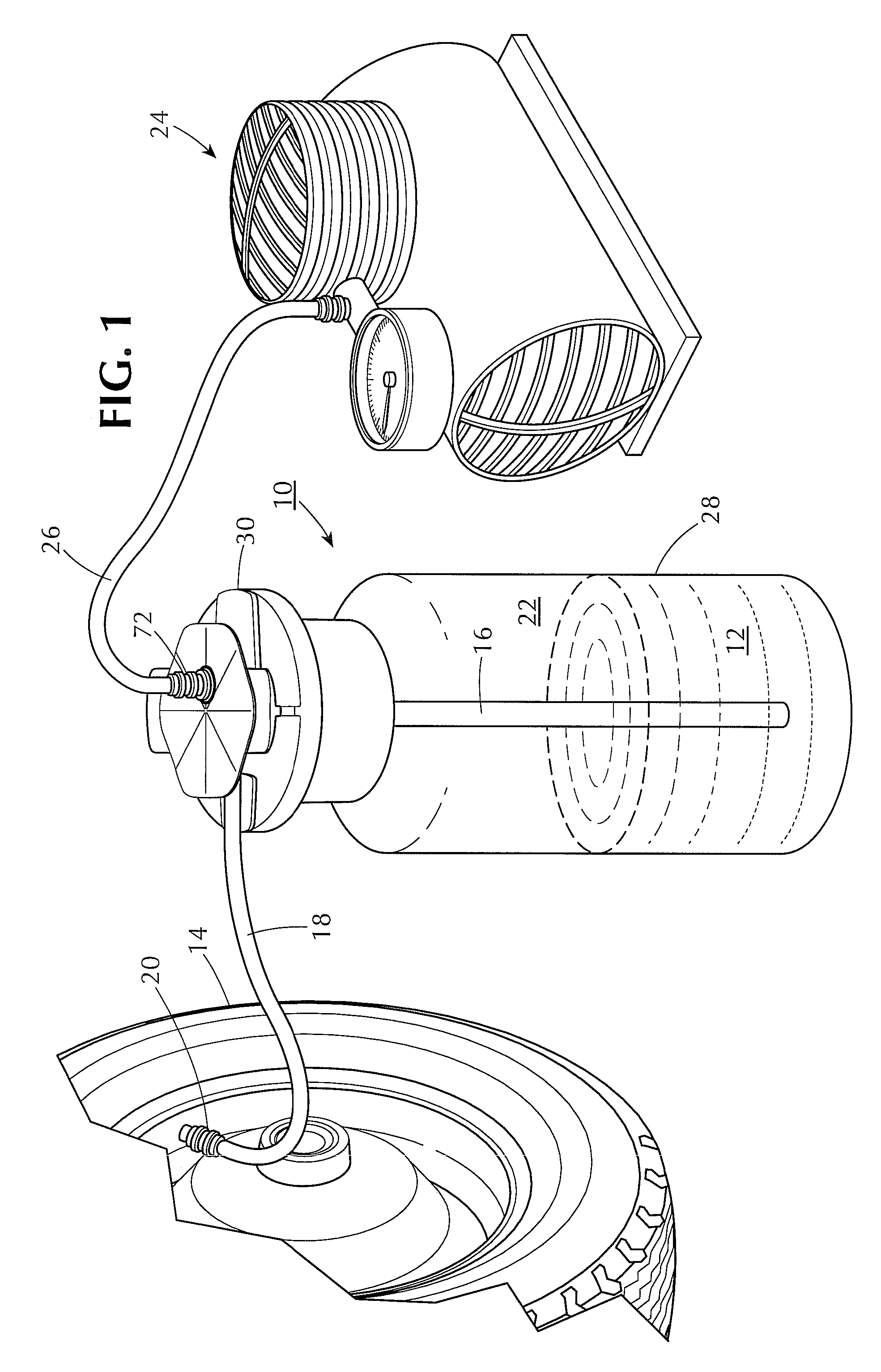

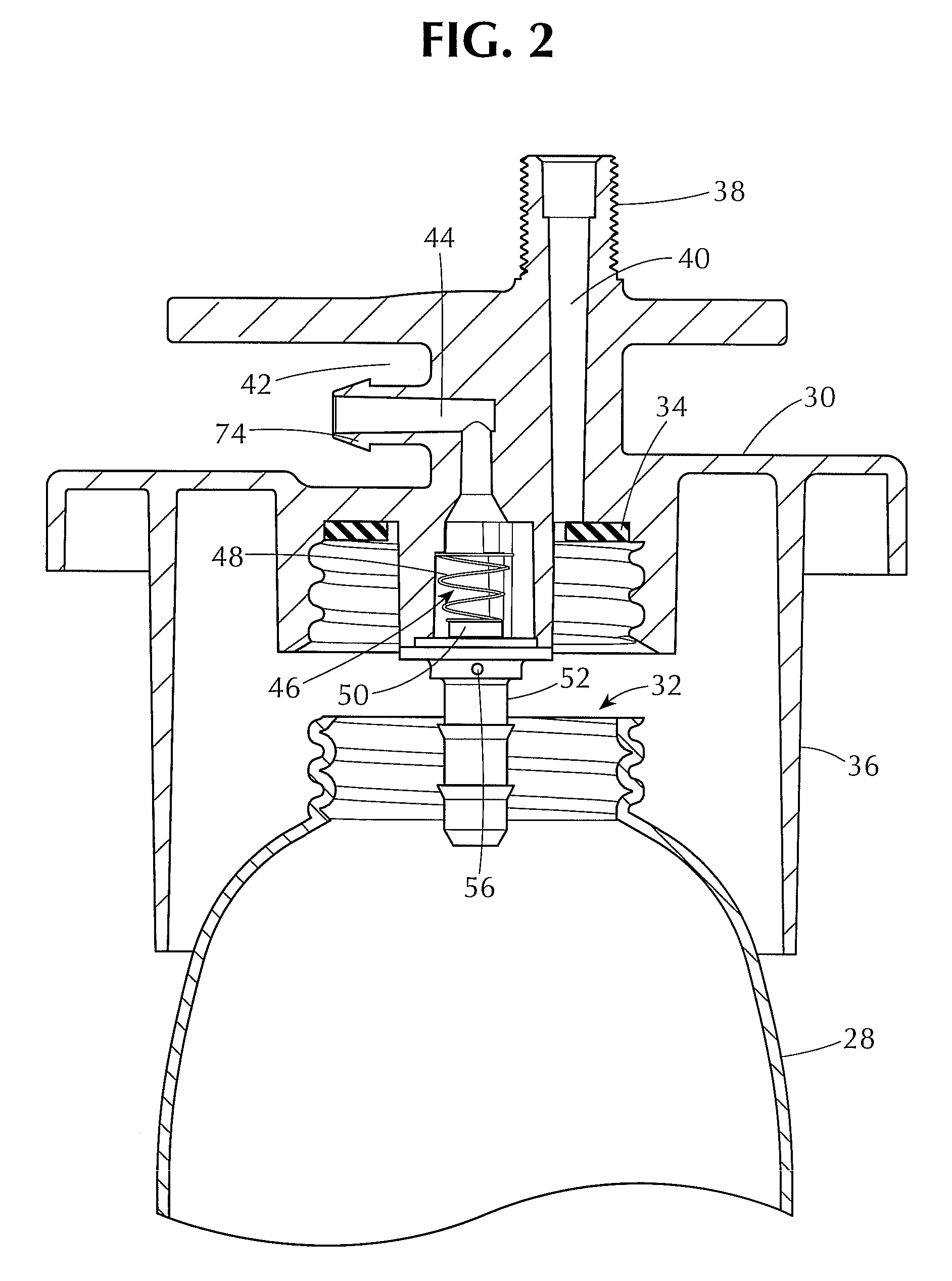

[0014]With initial reference to FIG. 1, the present invention comprises a container assembly 10 for a quantity of sealant fluid 12 intended to be injected into tire 14 to either seal a pre-existing puncture hole or to serve as a prophylactic against loss of air from the tire through a subsequent puncture. The sealant may be of a type generally known in the trade, including vinyl or cellulose-based types, with binders and clotting agents of the general type known in the art. The fluid contents 12 of the container assembly are directed upward through dip tube 16 and delivered to the interior of the tire through outlet tube 18, which terminates in a connector 20 of known construction that attaches to the inflation valve stem of the tire. The air space 22 above the sealant fluid 12 in the container assembly is pressurized to drive the fluid through the dip tube and outlet tube into the tire. The internal container pressure is developed by a suitable source of compressed gas, such as air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com