Particle sensor with wide linear range

a particle sensor and linear range technology, applied in the field of biomass and growth rate monitoring, can solve the problems of inability to conduct non-invasive measurements in many applications, the range of linearity achieved is still too limited for many applications, and the effect of adding more particles is non-additive, so as to reduce the sensitivity to the thickness of the container wall and rapid measurement of particle concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0134]The following are examples of methods and use of devices of the invention (e.g., for determination of particle concentration). It will be appreciated that such descriptions and examples are not necessarily limiting upon the current systems, methods, etc. and their use unless specifically stated to be so.

[0135]Example of Algorithm Applied to Reflectance Measurement of Biomass

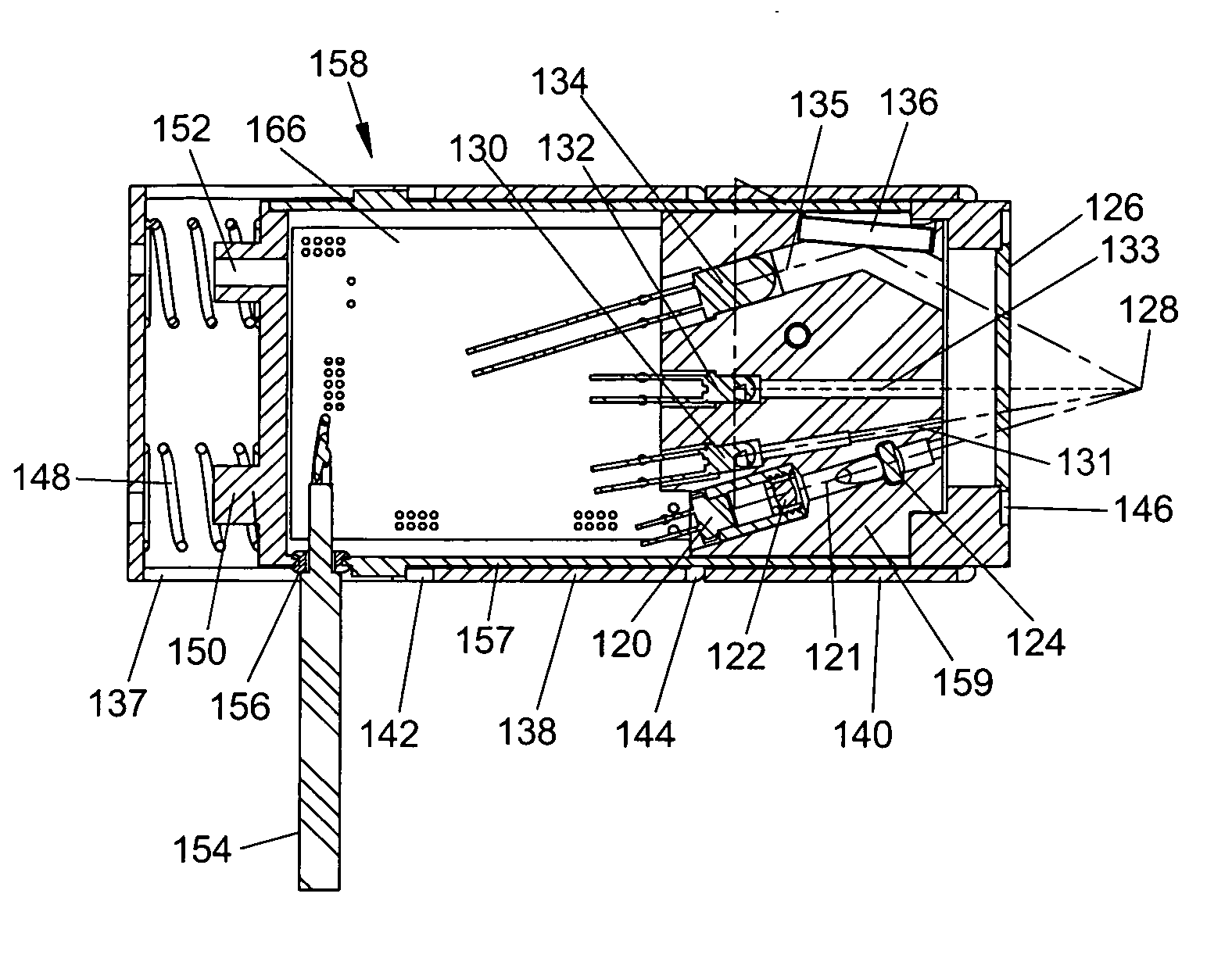

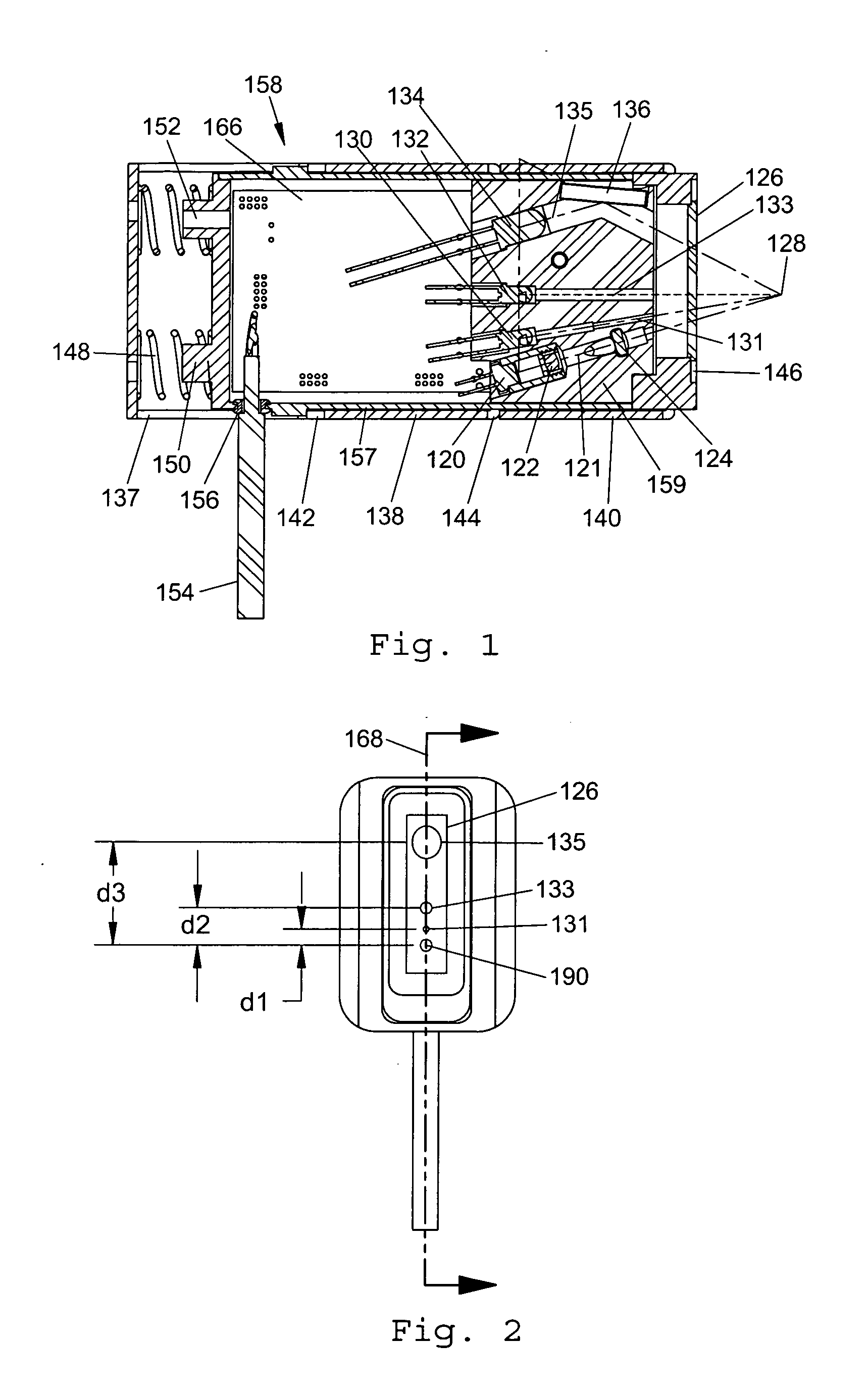

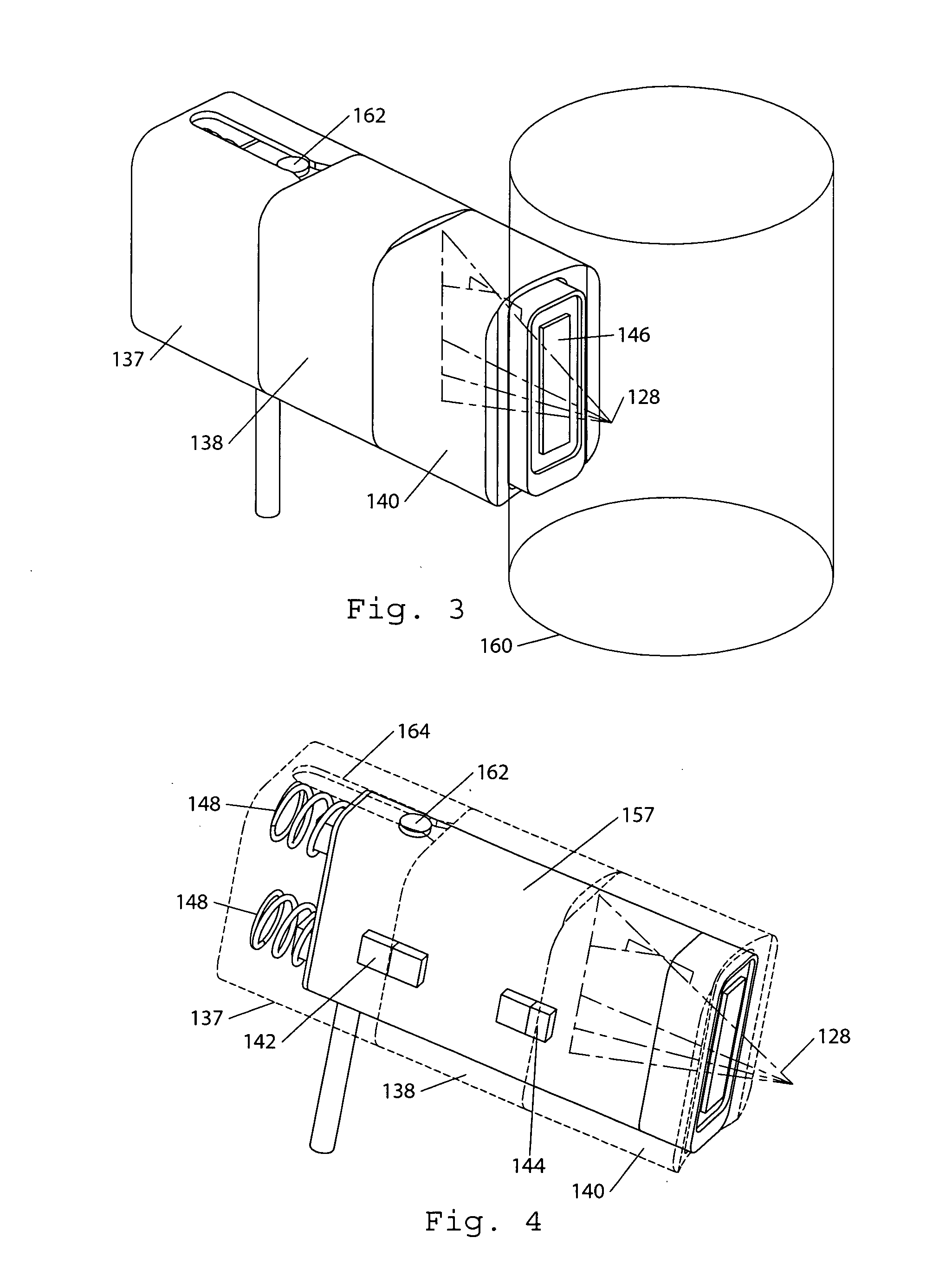

[0136]In this example, some of the algorithms of the present invention are applied to experimentally measured reflectance data. Measurements were made through the glass wall of a vessel containing a wide range of concentrations of Saccharomyces cerevisiae suspended in isotonic (0.9% w / v) saline. Such measurements can thus be used to determine offsets / multiplication factors to apply to measurement of unknown samples. See above. In the sensor used for this example, the source was a Vertical Cavity Surface Emitting Laser (VCSEL) emitting approximately 3 mW of power at 850 nm with a 3 degree divergence (Part No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com