Embroidery frame support device

a support device and embroidery frame technology, applied in the direction of embroidering machines, automatic machines, textiles and paper, etc., can solve the problems of affecting the operation efficiency of the embroidery frame, the front end portion of the embroidery frame bending, and the harmful influence of the sewing operation, etc., to achieve the effect of easily changing the embroidery frame of a different typ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]One embodiment of the present invention will hereinafter be described with reference to the accompanying drawings.

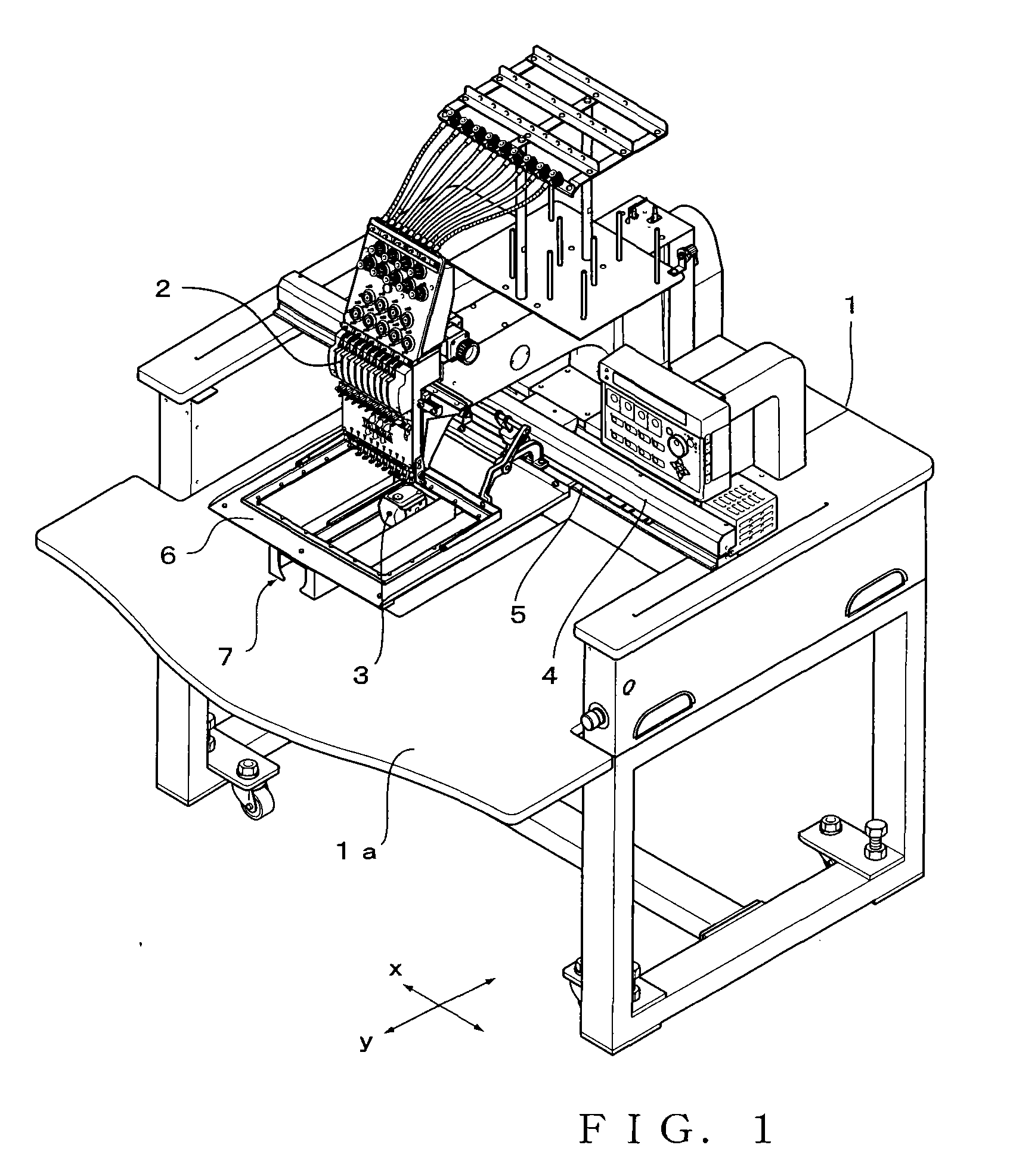

[0025]FIG. 1 is an overall perspective view showing a single-head embroidery sewing machine according to the present embodiment when viewed from a forward oblique upper side thereof. In the present embodiment, when the sewing machine is viewed from the front surface thereof, a right-and-left (horizontal) direction thereof is referred to as an “X direction”, while a front-and-behind direction thereof is referred to as a “Y direction”. In FIG. 1, a reference numeral 1 denotes a sewing machine table, a reference numeral 2 denotes a sewing machine head, and a reference numeral 3 denotes a cylinder bed. A front portion (front table) la of the sewing machine table 1 is configured to be capable of displacing upward and downward in a similar manner to this type of sewing machine known in the prior art. By displacing the front table la toward a lower position, it is possibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com