Portable drill pipe handling apparatus for use with oil and gas well drilling rigs

a technology for drilling rigs and handling equipment, applied in drilling pipes, drilling rods, drilling casings, etc., can solve the problems of occupying more space and typically stacked pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

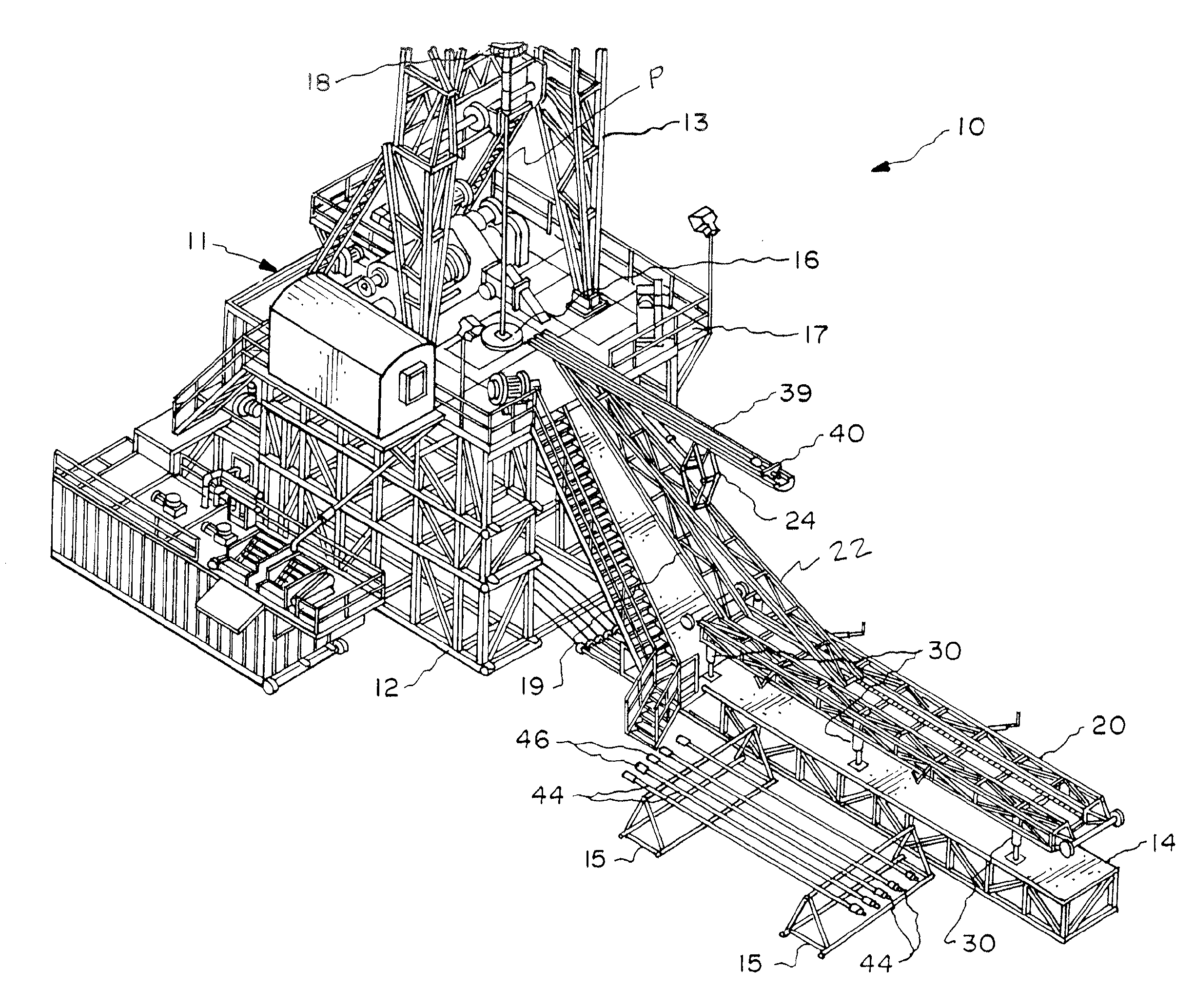

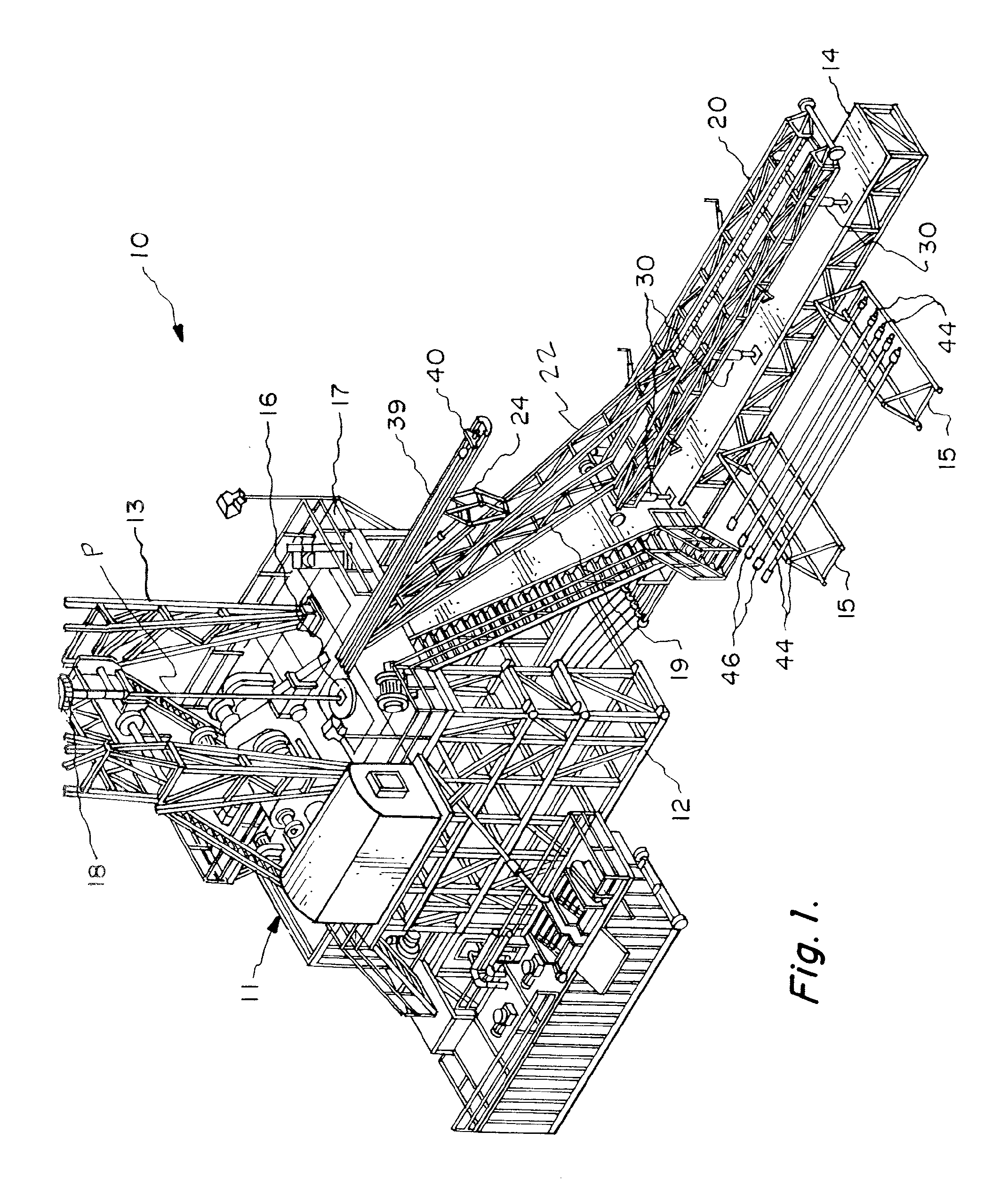

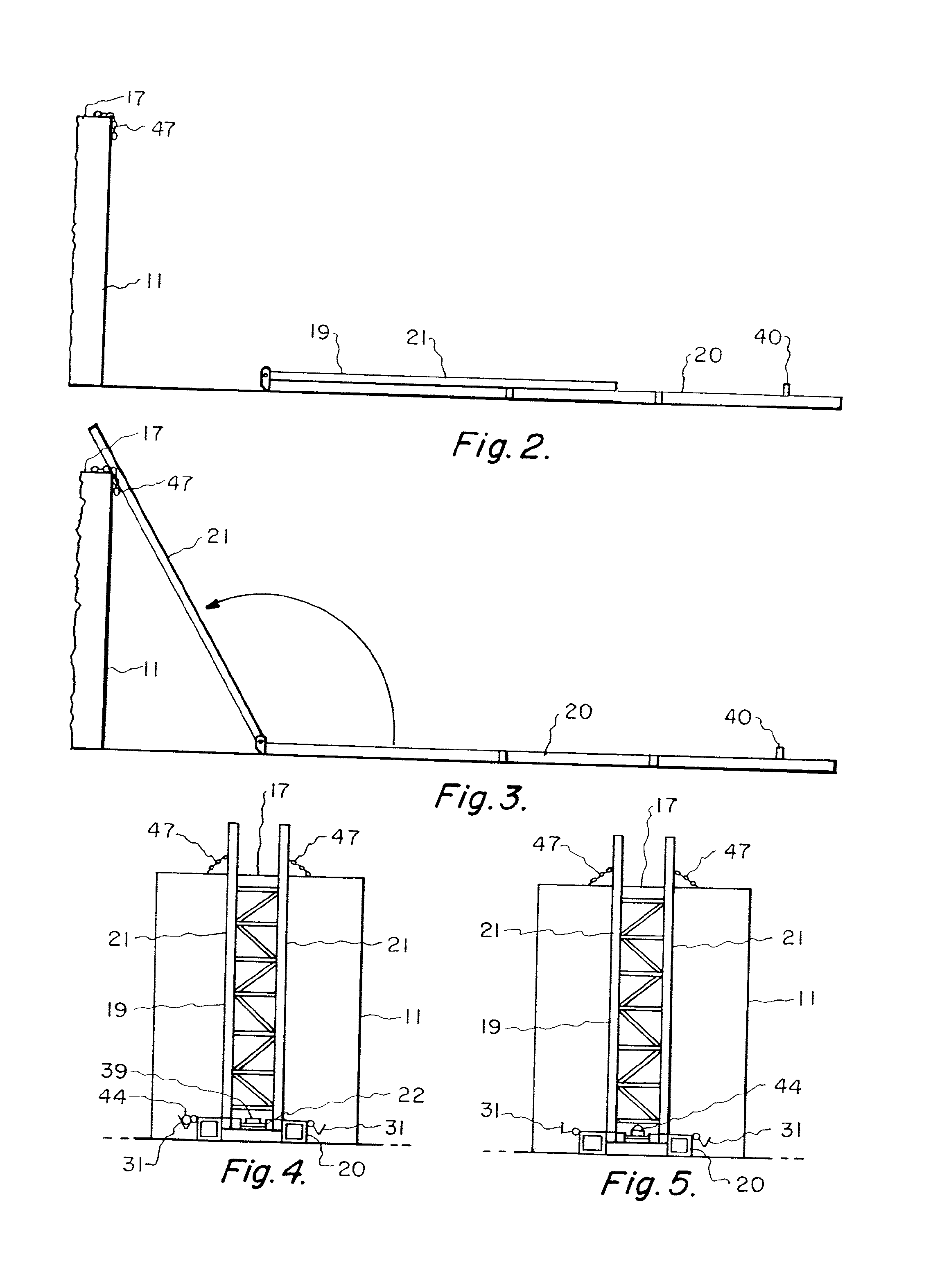

[0048]FIGS. 1-20 show the preferred embodiment of the apparatus of the present invention, designated generally by the numeral 10 in FIG. 1. Drill pipe transfer apparatus or “pipe skate: 10 is used with drilling rig 11, enabling the transfer of successive lengths or joints 44 of drill pipe that are stacked and stored in a generally horizontal position on a pipe rack 15, to an elevated deck or floor 17 of an oil and gas well drilling rig 11 having a base 12 (see FIG. 1).

[0049]The apparatus 10 of the present invention provides an optionally portable pipe skate for the safe transportation of the pipe joint members 44 from a horizontal position on pipe rack 15 and then diagonally to the drilling rig floor 17 and / or to a pipe elevator for vertical positioning (see pipe string P, FIG. 1) before transport into the well bore.

[0050]The apparatus 10 of the present invention includes a main frame 20 that can be positioned on the top of a drill rig catwalk 14. The apparatus 10 includes folding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com