Underground irrigation system

a technology of irrigation system and irrigation system, which is applied in the direction of watering devices, soil drainage, construction, etc., can solve the problems of prone to breakdown of sprinkler heads, nozzles that are somewhat expensive, and conventional underground sprinkler systems incorporating sprinkler nozzles exhibit a number of problems, and achieve the effect of simple and inexpensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

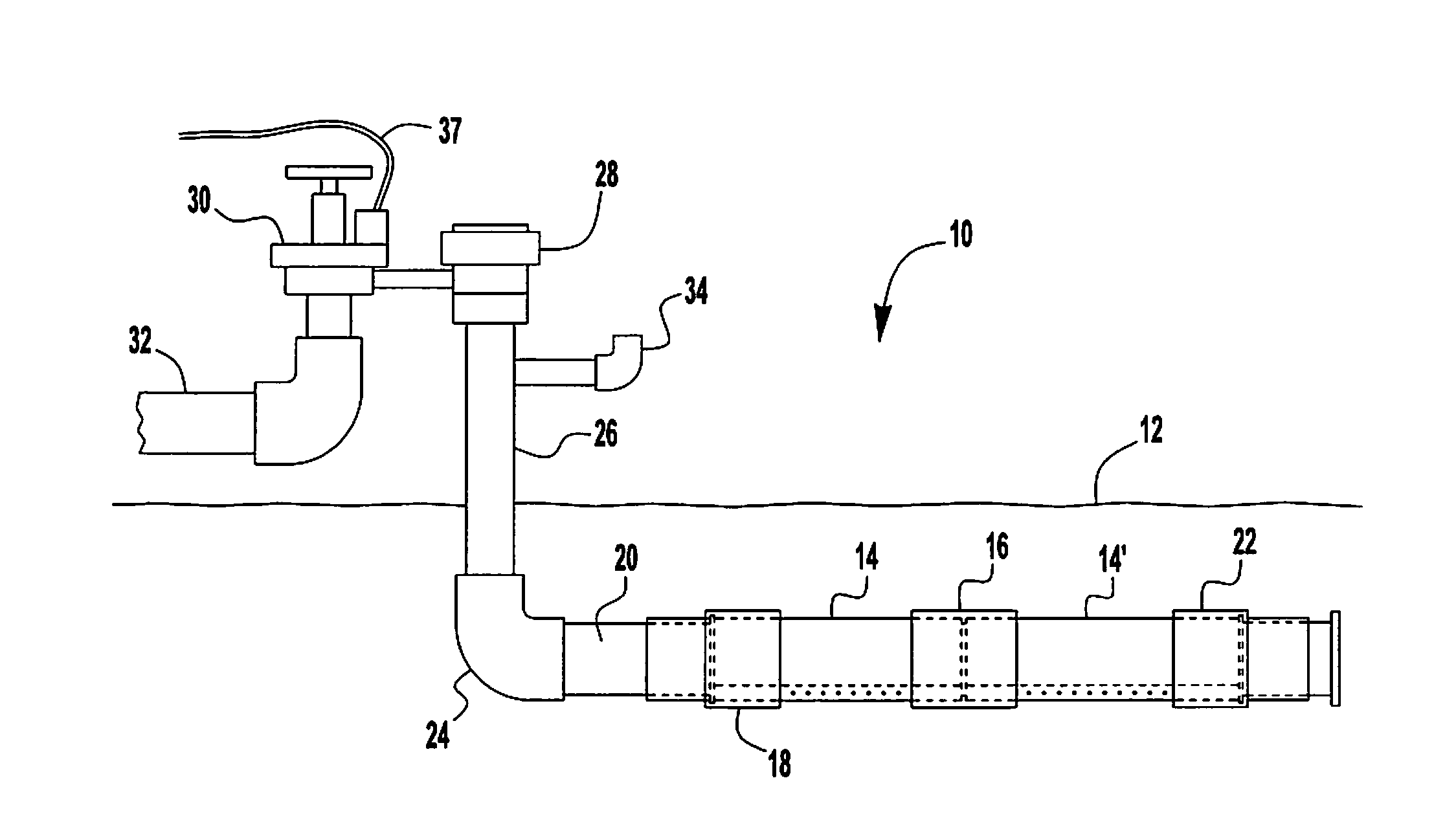

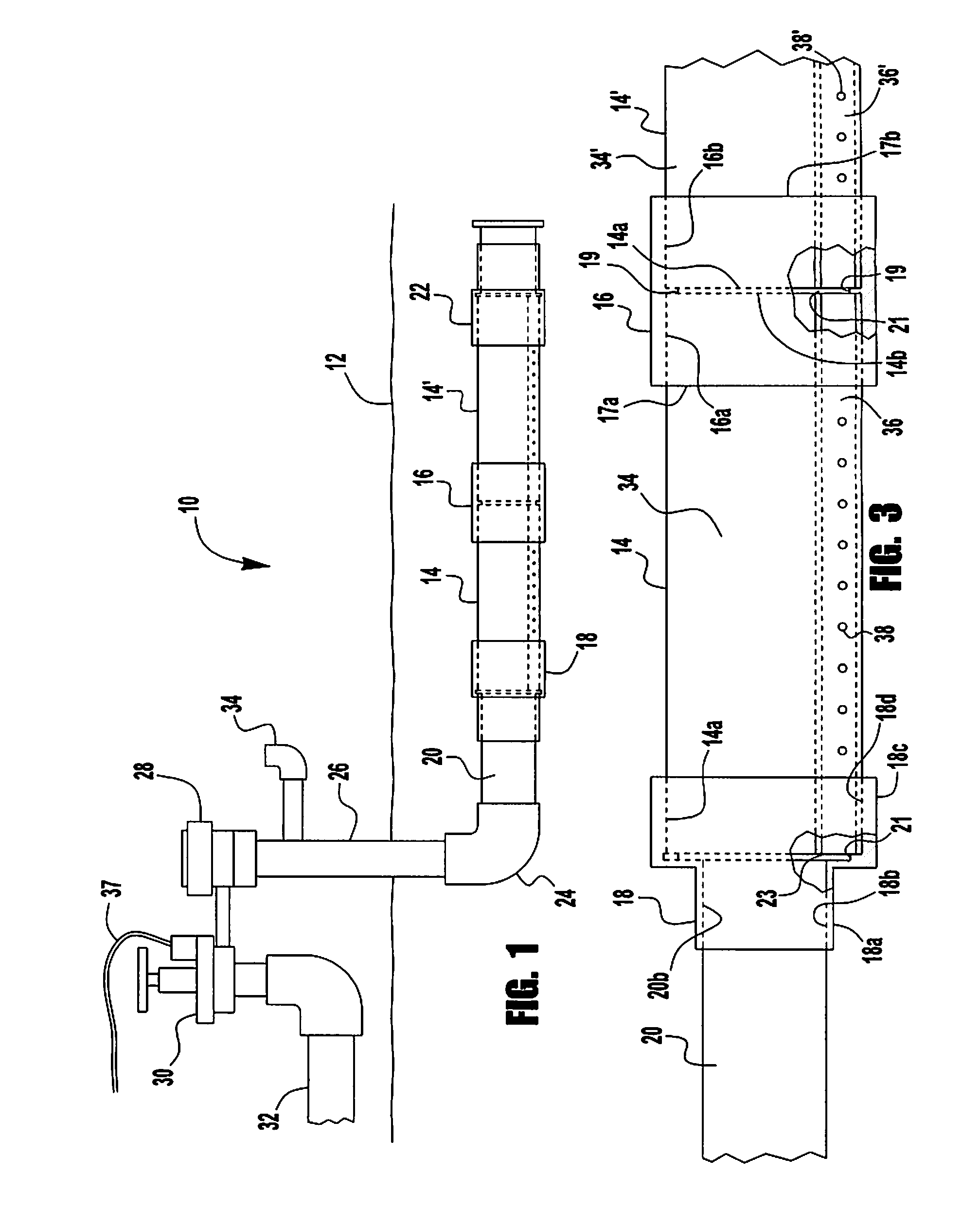

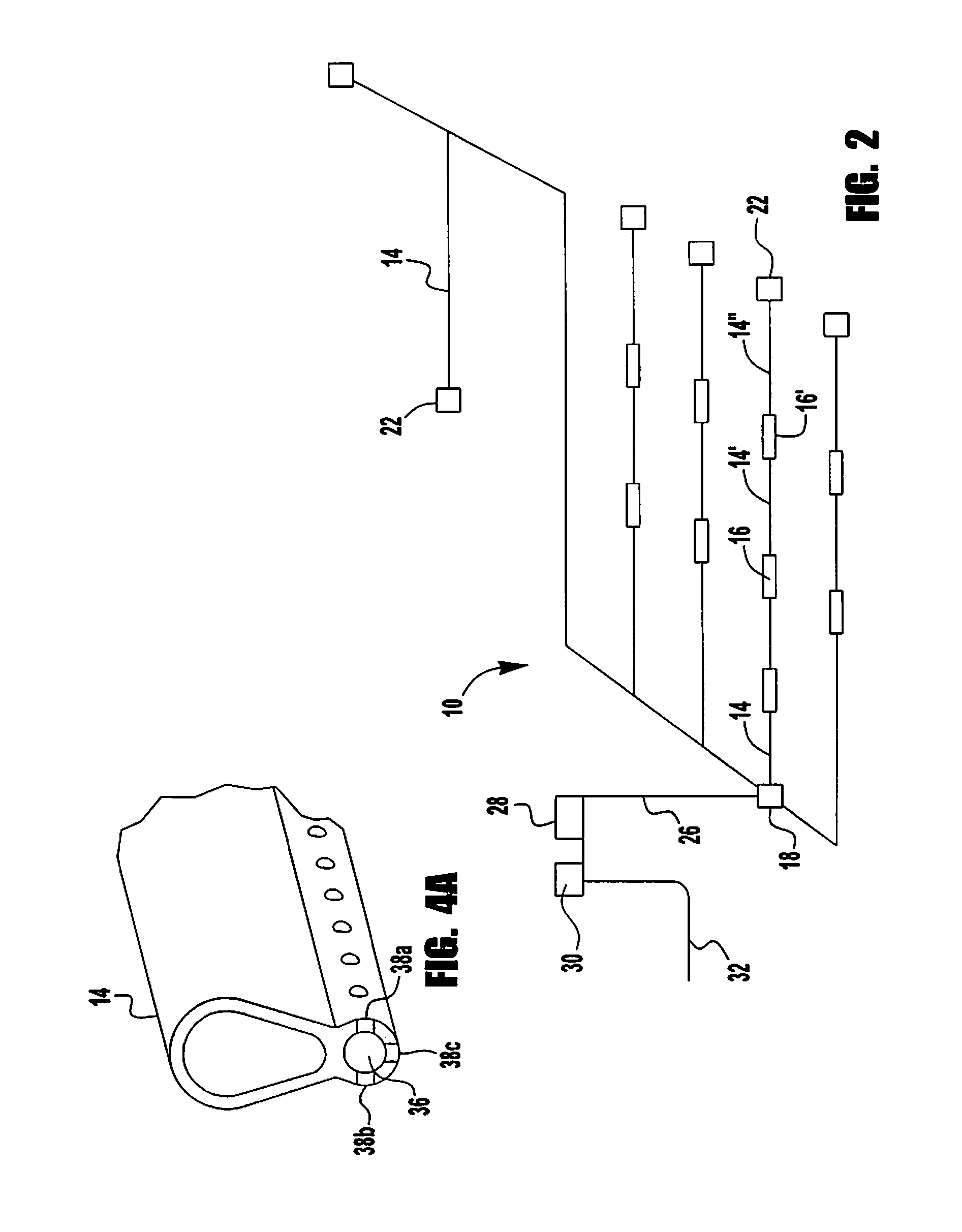

[0043]FIG. 1 illustrates the basic components of an irrigation pipe system 10 which is preferably buried below ground surface 12 to any desired depth such as for example, 5 cm to 50 cm. The depth of the irrigation pipe system 10 preferably corresponds to the depth of the roots of the agricultural growth which is being irrigated. As shown in FIG. 2, the irrigation pipe system 10 can be laid out in any desired configuration as discussed in more detail herein after.

[0044]The primary components of the irrigation pipe system 10, as shown in FIG. 1, can include an irrigation pipe section 14, an irrigation pipe section coupling 16 adapted for connecting two irrigation pipe sections 14 and 14′ together as shown in FIGS. 1 and 3, an irrigation pipe section inlet end coupling 18 adapted for connecting an irrigation pipe section 14 to a conventional inlet pipe 20, and an irrigation pipe section outlet end coupling 22 adapted for closing an end of a length of interconnected irrigation pipe sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com