Gas sensor, air-fuel ratio controller, and transportation apparatus

a technology of air-fuel ratio and gas sensor, which is applied in the field of gas sensors, can solve the problems of adding to production costs, difficult to control the air-fuel ratio with a high precision, and inability to control the temperature of the sensor, etc., and achieves the effect of accurate and simple manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. Although an oxygen sensor for detecting oxygen preferably is exemplified below, the present invention is not limited to an oxygen sensor, but can be suitably used for gas sensors including a heater.

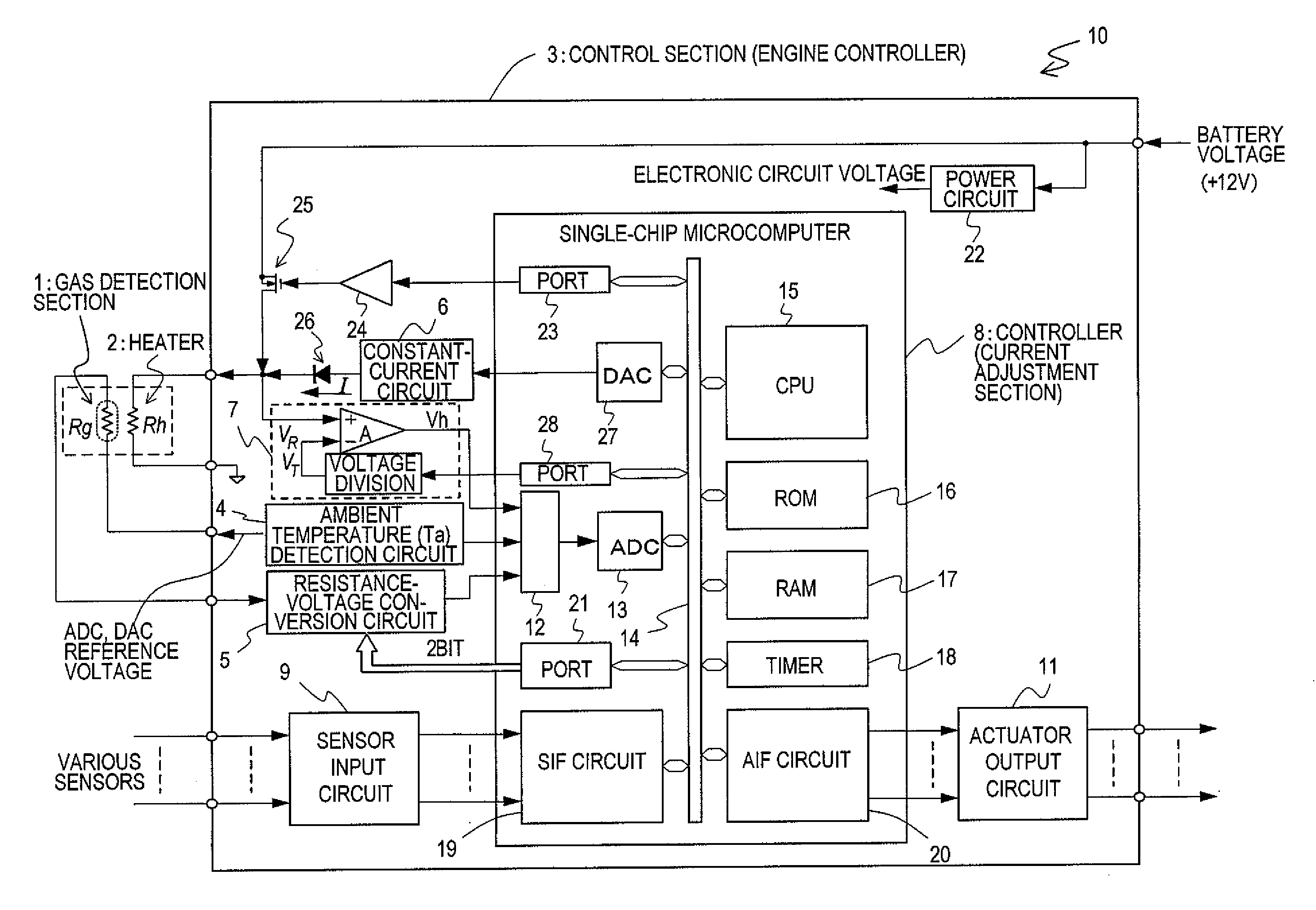

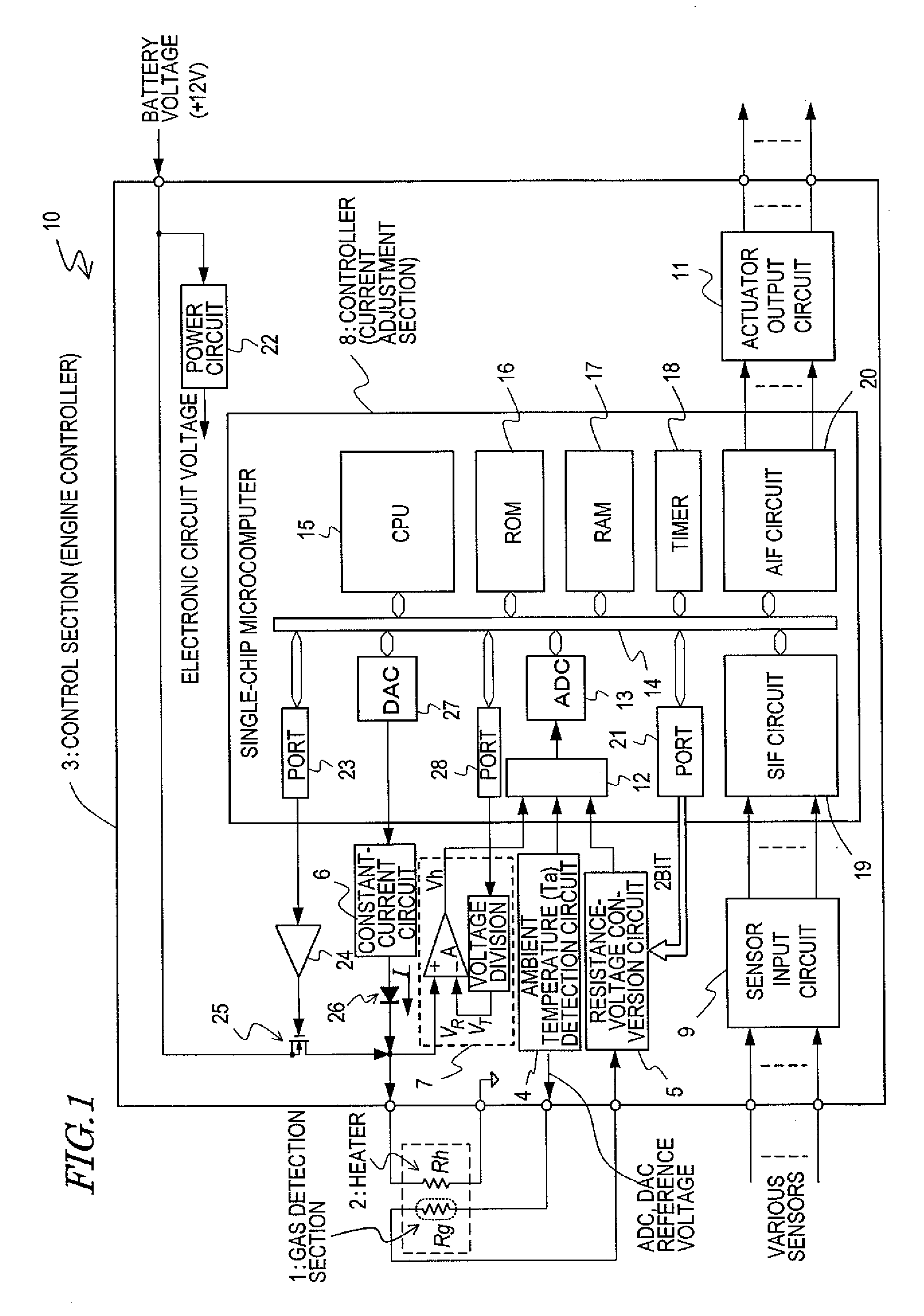

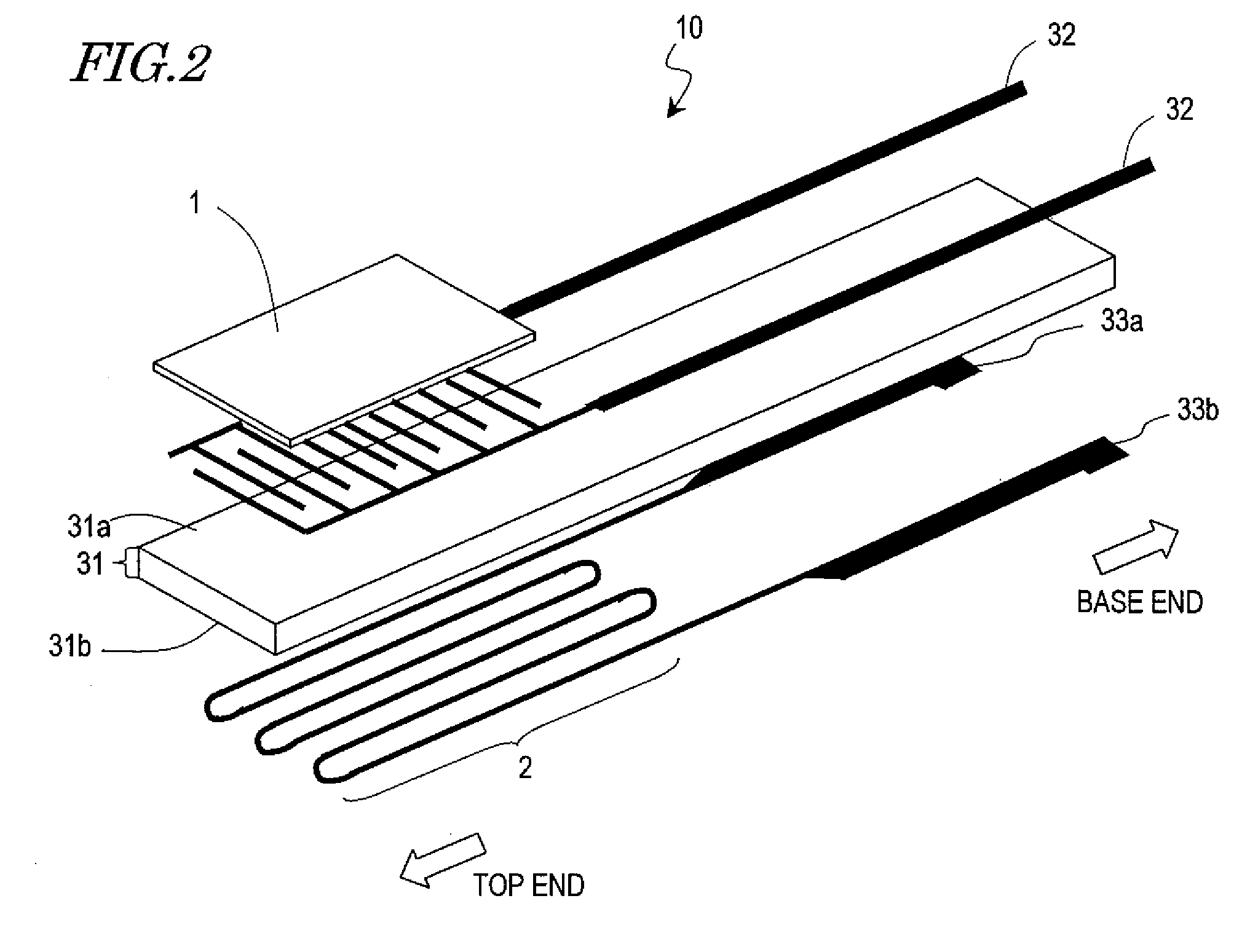

[0058]FIG. 1 is a circuit diagram showing the construction of an oxygen sensor 10 according to a preferred embodiment of the present embodiment. As shown in FIG. 1, the oxygen sensor 10 includes a gas detection section 1, a heater 2 for elevating the temperature of the gas detection section 1, and a control section 3 for controlling the operation of the heater 2.

[0059]The gas detection section 1 detects the concentration and / or amount of a predetermined gas that is contained in an atmosphere which is in contact with the gas detection section 1. The gas detection section 1 of the present preferred embodiment is a so-called resistance type, whose resistance value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com