Knockdown modular mattress

a mattress and modular technology, applied in the field of mattresses, can solve the problems of not being accepted commercially, not being able to disclose the combination of elements that can not only be assembled, and all lack an acceptable finished mattress look to the end user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

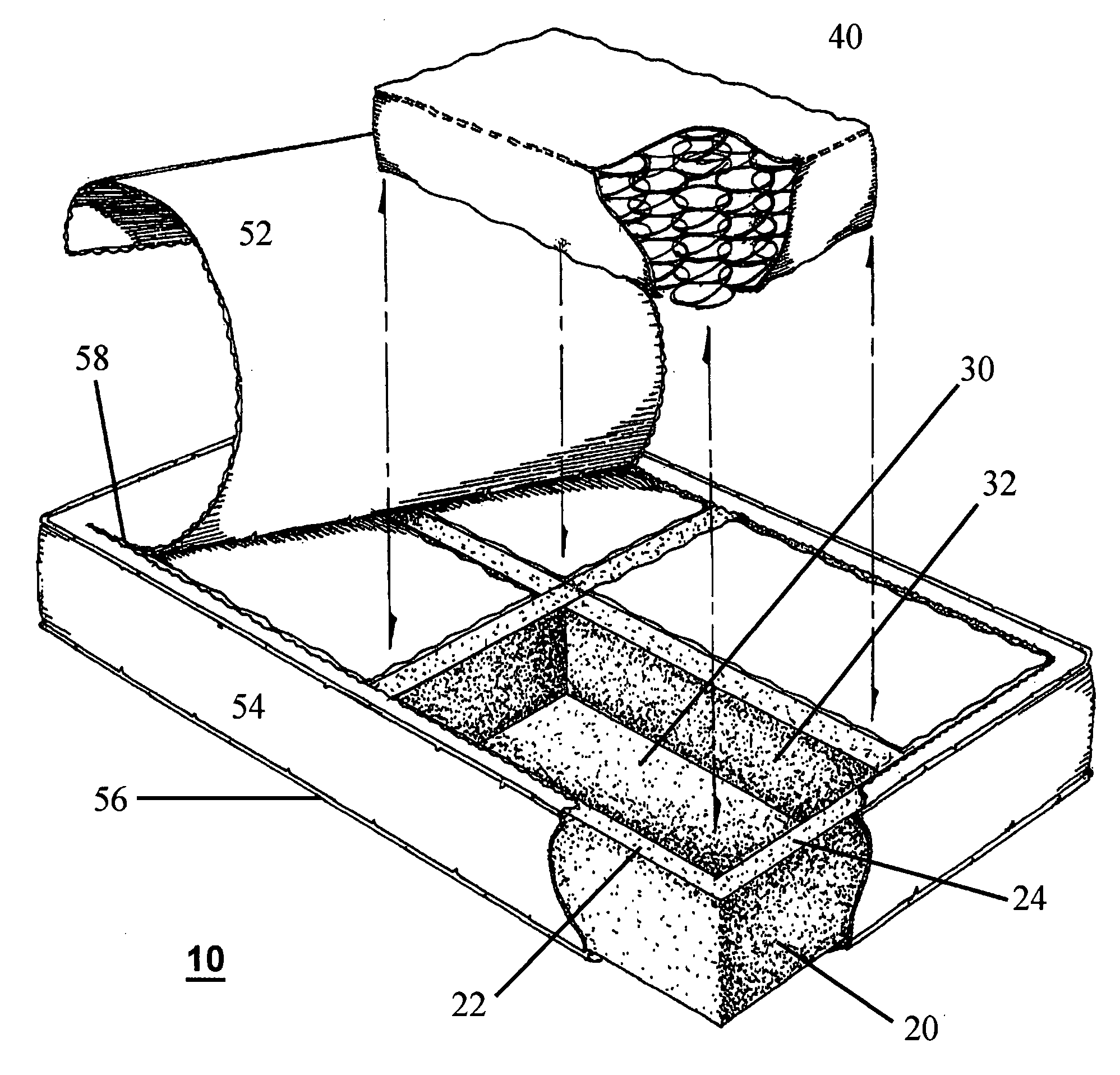

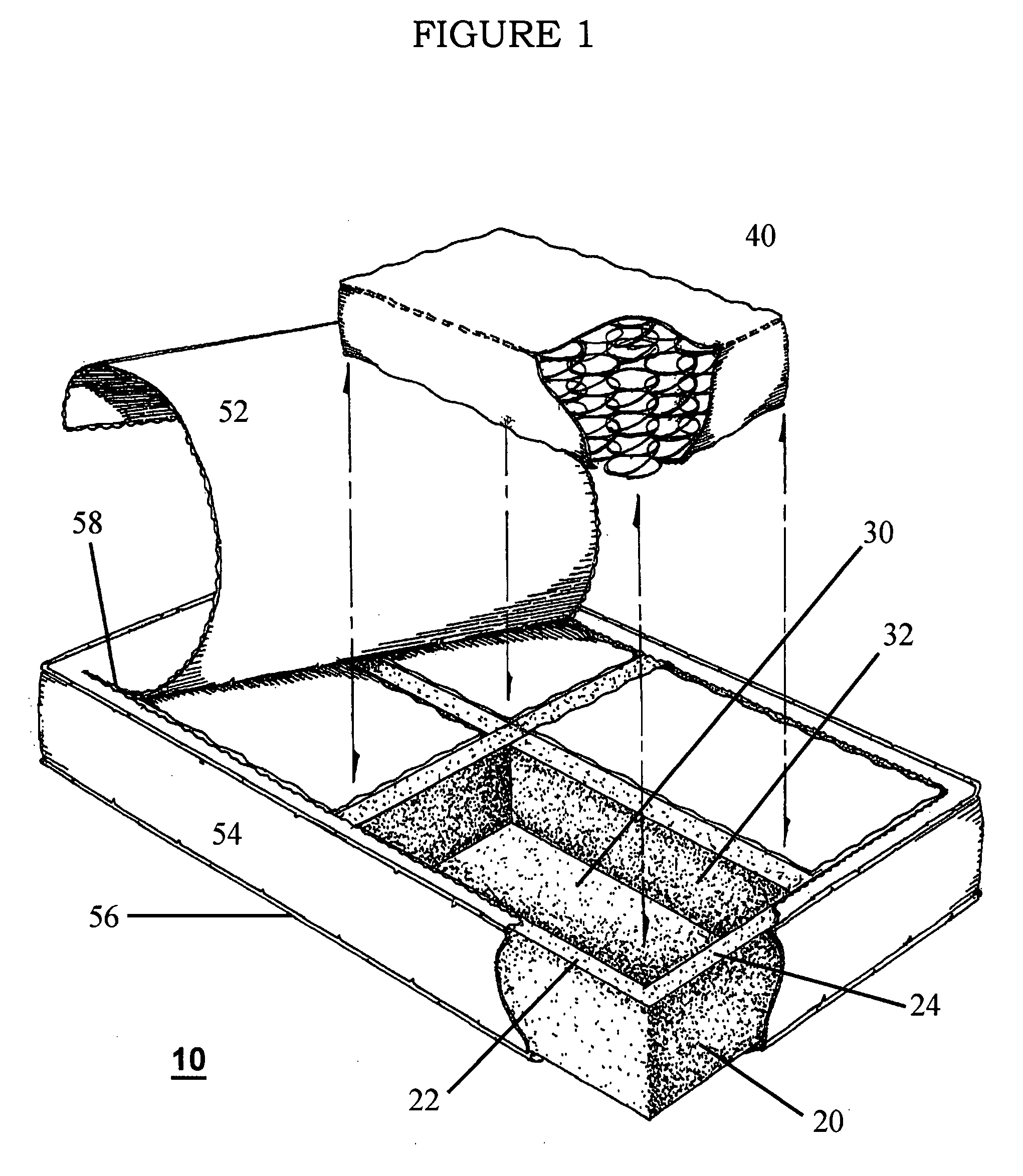

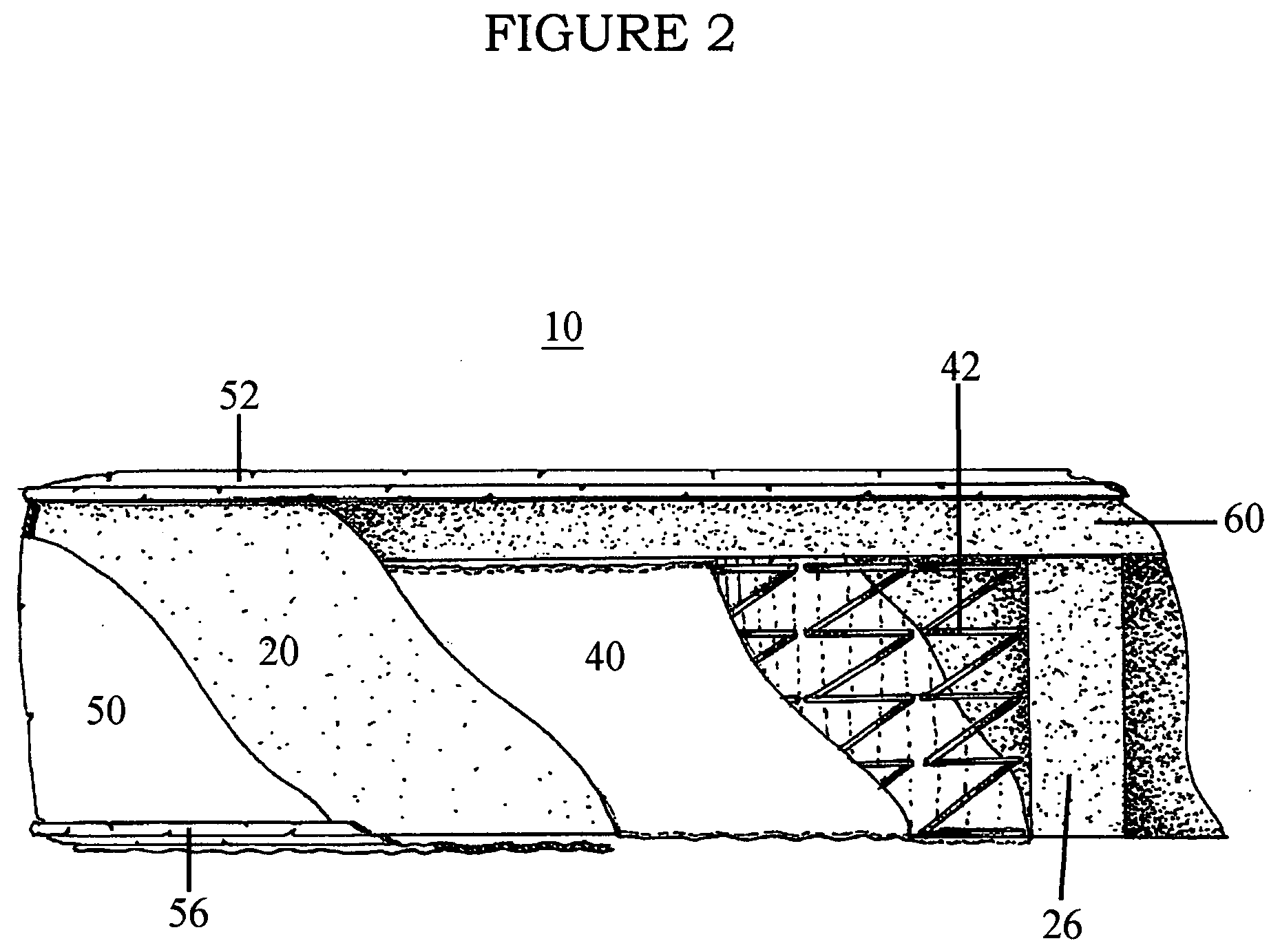

[0023]A preferred modular mattress embodiment is shown in the FIGUREs. As seen in FIG. 1, the combination of elements for this mattress includes the following: a peripheral support module (20), at least two mattress chambers (30), a plurality of internal support modules (40), and a mattress cover (50).

[0024]The peripheral support module can be constructed in several ways. It can be molded as one piece. It can be fabricated by cutting a single piece of foam. Or it can be made by gluing pieces of foam that make up the individual lengths and widths of the peripheral support module. The peripheral support module is comprised of a supportive and compressible bedding foam such as high density polyurethane. As shown in the FIGUREs, the perimeter or bolster rails of the peripheral support module extend inward about one foot, enabling a typical user to sit on the edge of the assembled mattress. The bolster firmness is greater than that of the internal support module. Preferably, a longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com