Enhanced evaporative cooling system

a technology of evaporative cooling and enhanced cooling, which is applied in chemical protection, nuclear engineering, nuclear elements, etc., can solve the problems of reducing cooling, waste of evaporative cooling potential of sweat, and less surface area, and achieves enhanced evaporative cooling of the body and better use of water. the effect of the expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

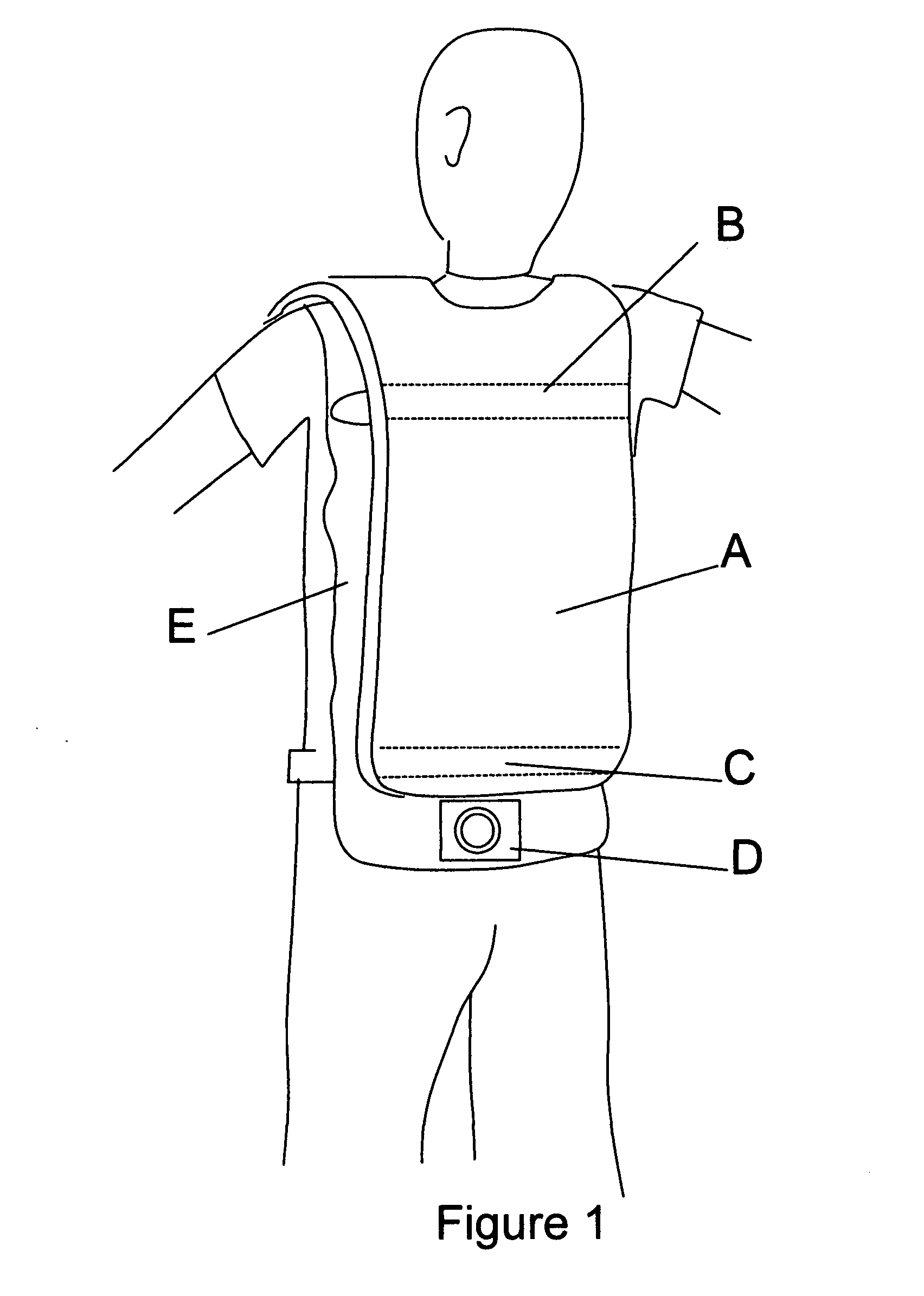

[0017]FIG. 1A sheet 1 is a protective vest such as the Interceptor vest. The protective vest is supported from the body by structures B and C in FIG. 1 sheet 1. FIG. 1E sheet 1 is an absorbent material such as cotton cloth however any material that will transfer moisture will work. Even plastic will blot water from a surface. FIG. 1E sheet 1 is separate from the Interceptor vest in this embodiment but it could be an integral part of the protective vest. D in FIG. 1 sheet 1 is a blower that blows air under the absorbent layer FIG. 1E sheet 1. The air from the blower will remove moisture through evaporation and cool the wearer. Humid conditions require more air but still cools the individual. The volume of the air necessary is proportional to the relative humidity until the air being pumped in is one hundred percent saturated.

[0018]FIG. 1 sheet 2 shows a cross section of the sectional side view of the torso with absorbent material and protective vest and shows the absorption of envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com