Sealing device for joint section of robot and articulated robot having the same

a joint section and sealing device technology, applied in mechanical control devices, process and machine control, instruments, etc., can solve the problems of difficulty in preventing foreign matter from penetrating through the labyrinth seal into the wrist housing, and the sealing device may not sufficiently seal in the lubricant,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The embodiments of the present invention are described below in detail, with reference to the accompanying drawings. In the drawings, same or similar components are denoted by common reference numerals.

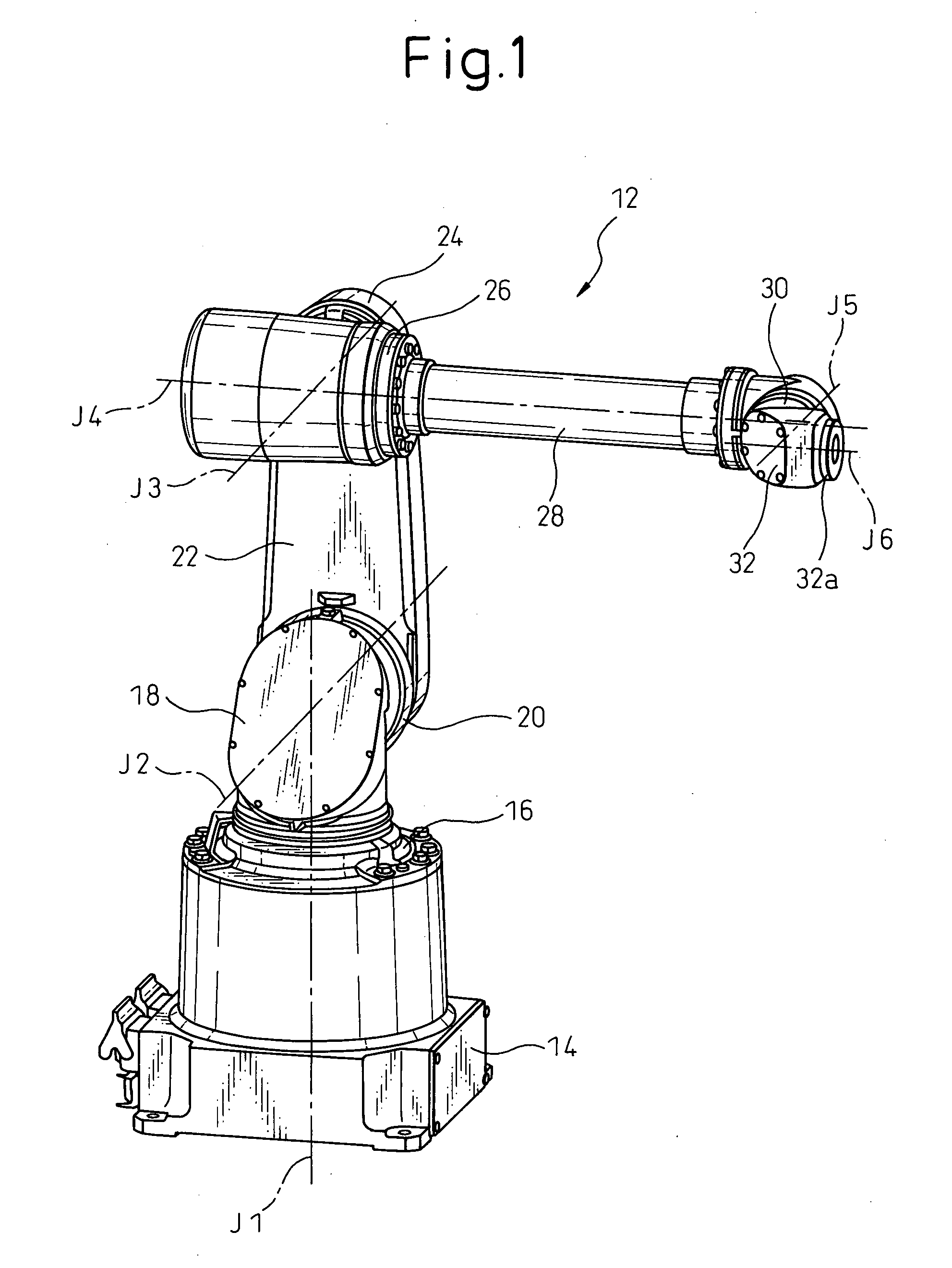

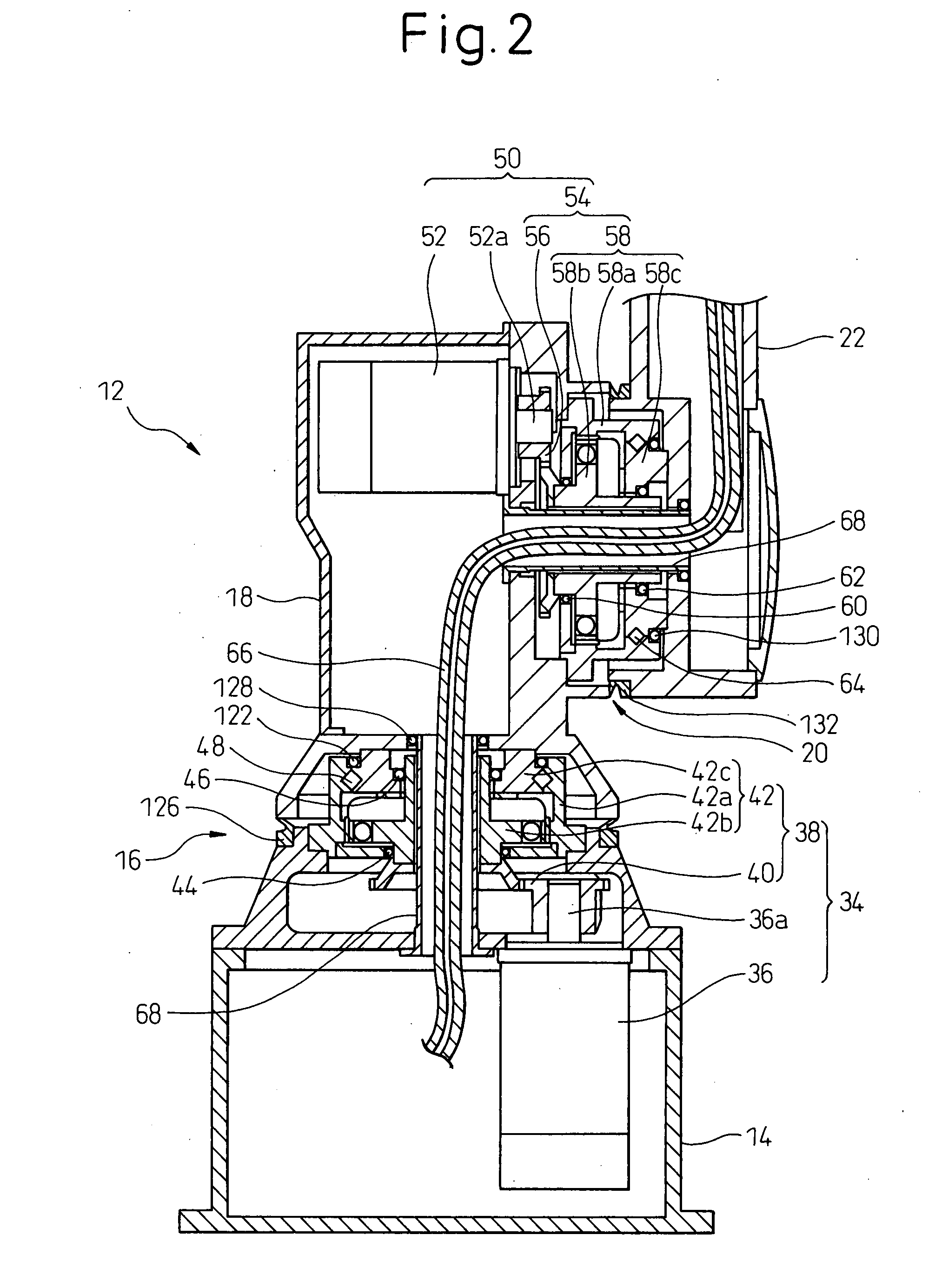

[0023]Referring to the drawings, FIG. 1 shows an articulated robot 12 (hereinafter simply referred to as a robot 12) according to an embodiment of the present invention and provided, in each joint section thereof, with a sealing device 10 according to an embodiment of the present invention; FIGS. 2 and 3 show the internal structures of joint sections of the robot 12; and FIGS. 4 and 5 show an enlarged view of the configurations of the sealing devices 10 provided to the joint sections of the robot 12. The robot 12 is shown to have a mechanical configuration of a 6-axis vertical articulated robot provided mainly with joint sections having a direct drive structure. However, the robot according to the present invention is not limited to this mechanical configuration.

[0024]As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com