Solid-state microsecond capacitance charger for high voltage and pulsed power

a capacitance charger and microsecond technology, applied in pulse generators, pulse techniques, pulse manipulation, etc., can solve the problems of high price, large number of transistors summing through transformers, and relatively unreliable thyratrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

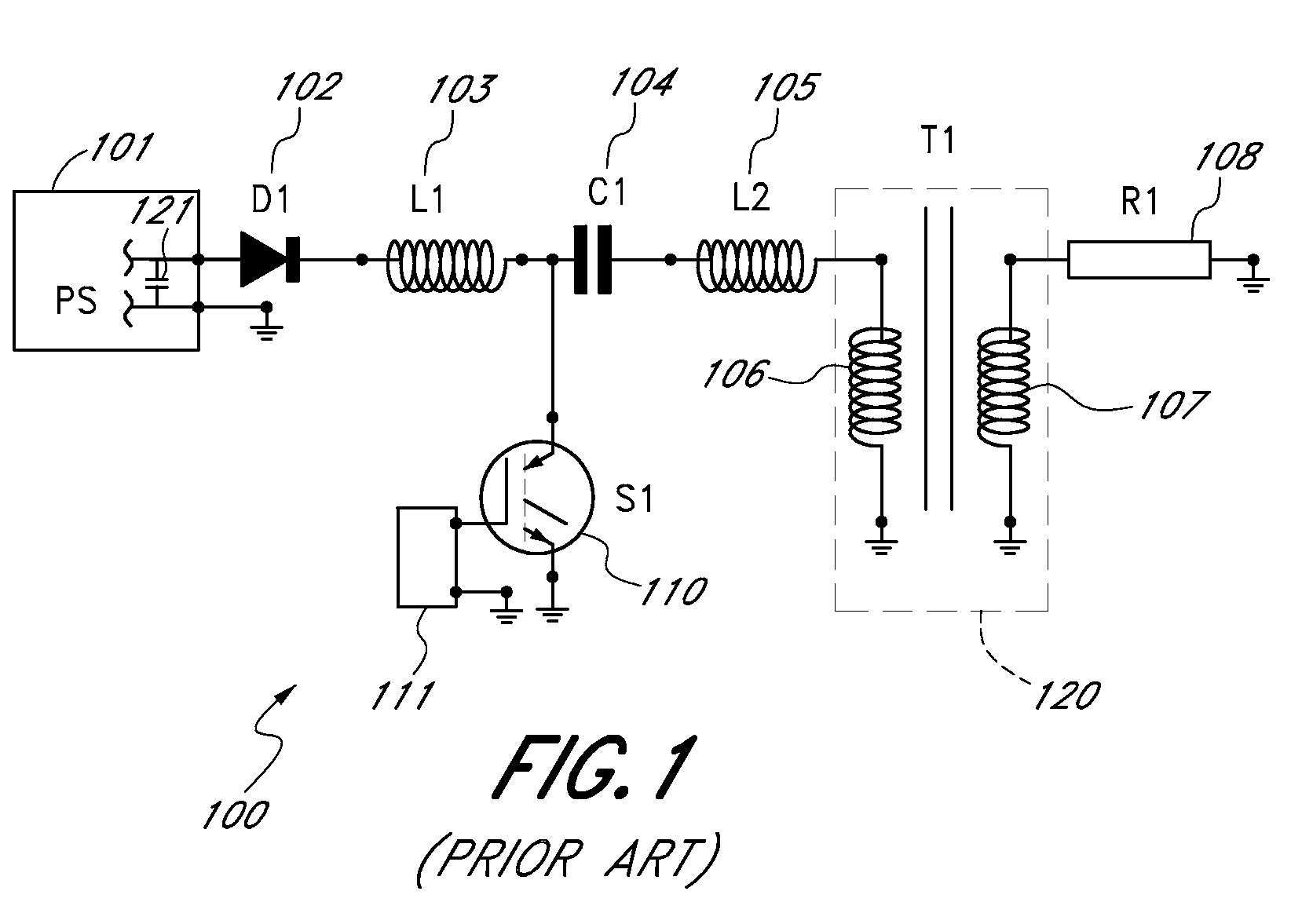

[0030]FIG. 1 shows a simple resonance charging system 100, where a power supply 101 provides a DC output voltage through a diode 102. The power supply 101 includes a filter capacitor 121 to filter the output voltage of the power supply 101. An output of the diode 102 is provided through an inductor 103 to a first terminal of an intermediate capacitor C1104. A second terminal of the capacitor C1104 is provided to ground through a series connection of an inductor 105 and a primary winding 106 of a transformer 120. A solid-state switch 110 is provided between the first terminal of the intermediate capacitor C1104 and ground. A control circuit 111 controls the solid-state switch 110. A secondary 107 of the transformer 120 is provided to a load 108. The charging system 100 doubles the voltage of the filter capacitor 121 by charging the intermediate capacitor.

[0031]In one embodiment, the capacitor C1104 is resonance charged to 320 volts from a 160 volt DC power supply. When the solid-stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com