Method and apparatus in a paper or board machine for confining pulp flow from the headbox

a technology of confining pulp flow and paper or board machine, which is applied in the field of method and apparatus in paper or board machine for confining pulp flow from the headbox, can solve the problems of deckle sealing effect and deckle lubrication deficiency in practice, and achieve the effect of reducing or even completely preventing the formation of edge undulation, reducing the range of basis weight variation in the edge area of the machine, and ensuring the integrity of the machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

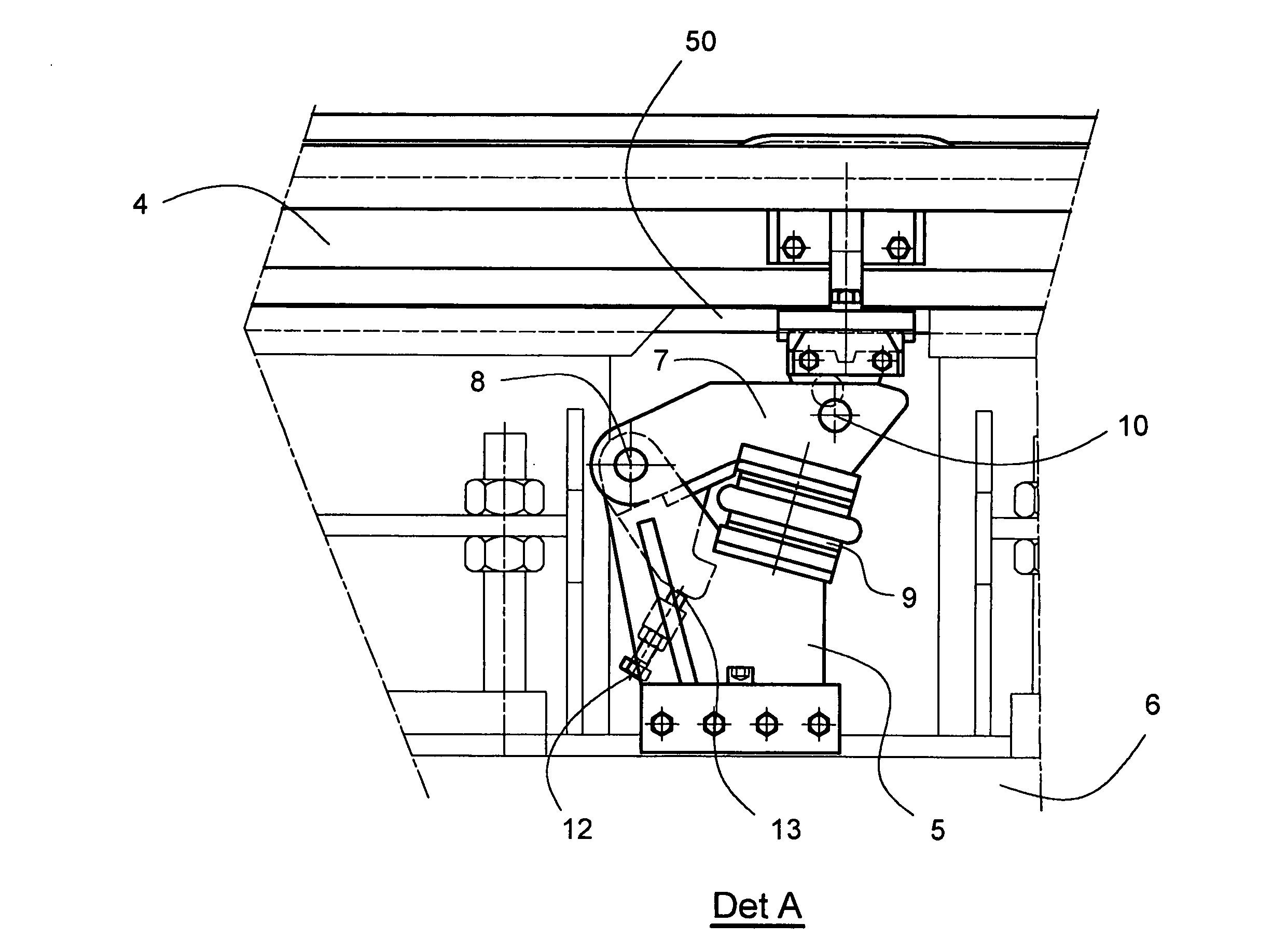

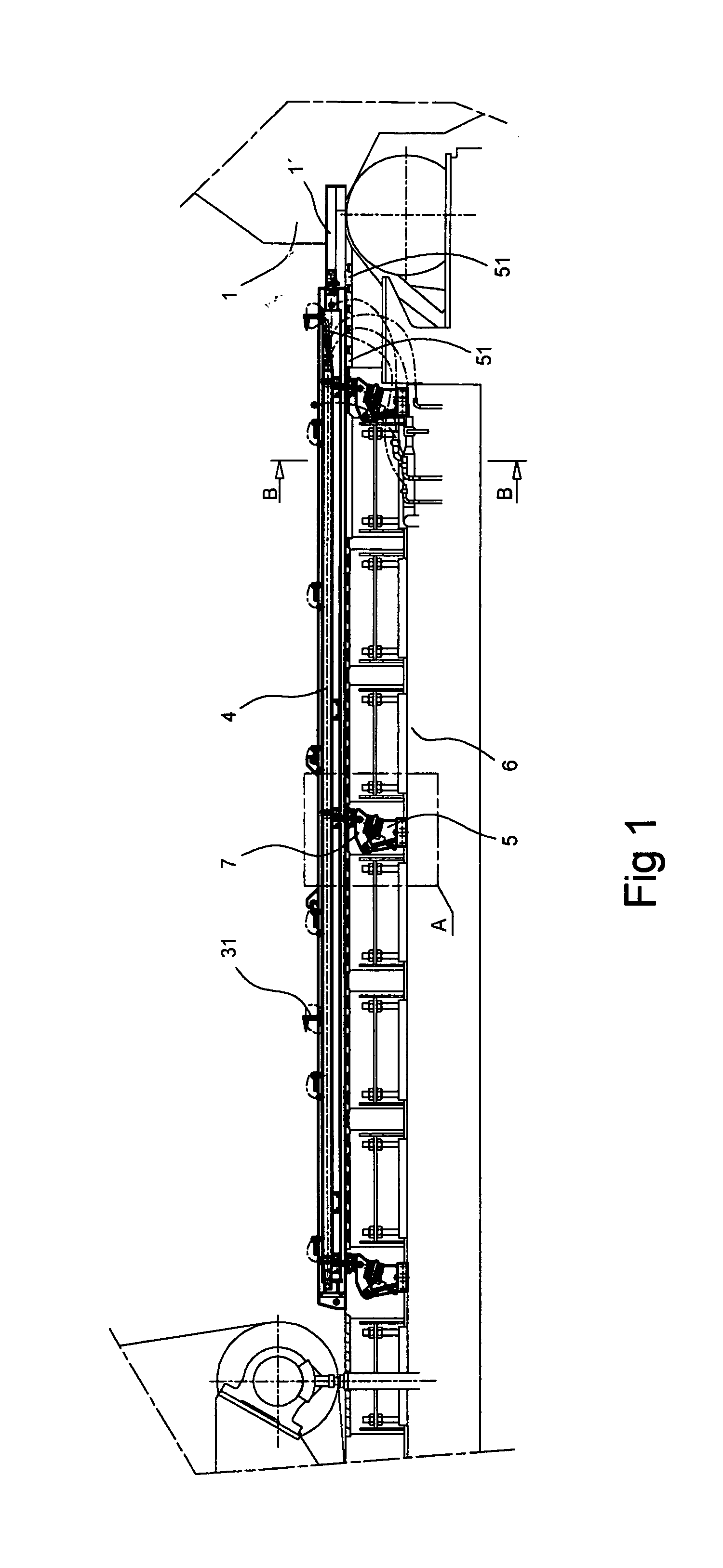

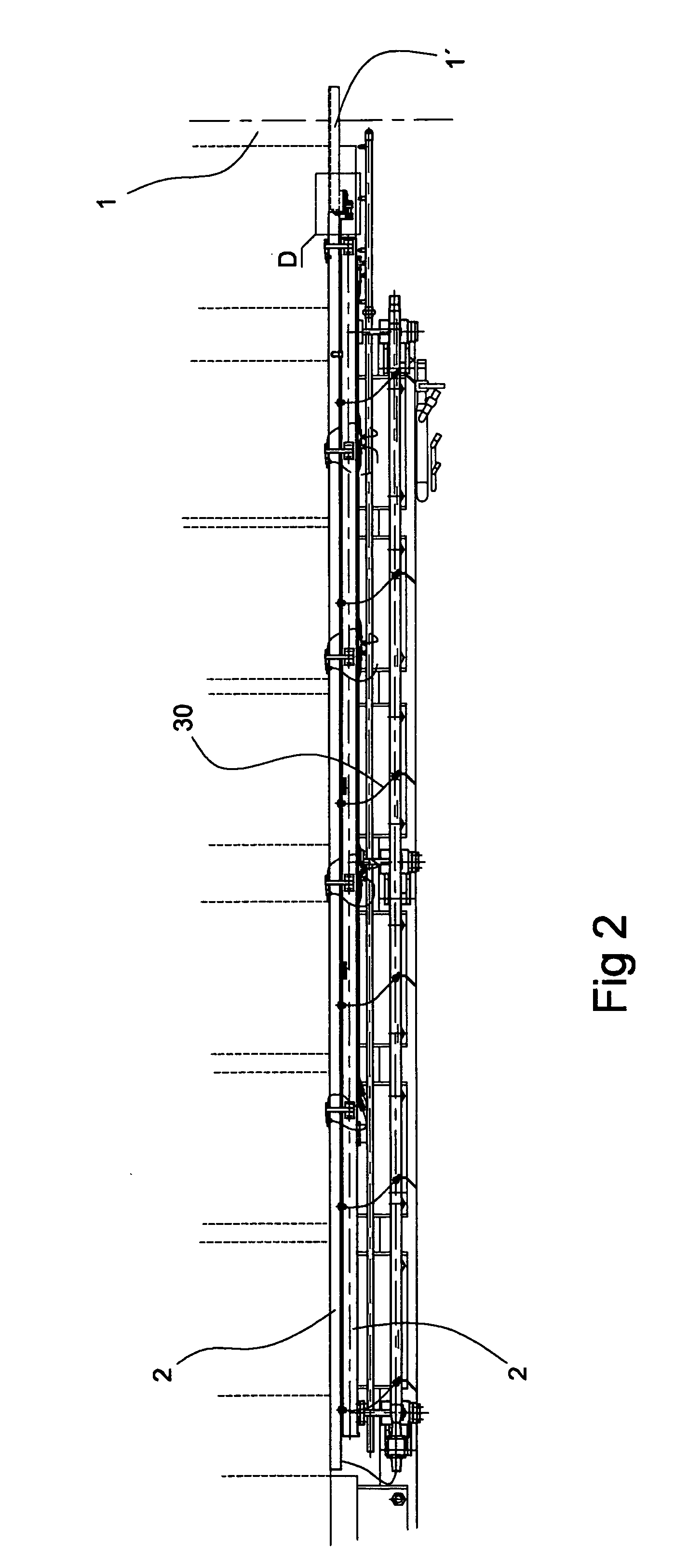

[0017]FIGS. 1 and 2 show an apparatus according to the invention in connection with the forming section of a paper machine. The figure shows only one deckle. Typically, the forming section is provided with two deckles, one in or in the vicinity of each edge area of the wire of the forming section. FIG. 6 illustrates the invention in more detail.

[0018]The invention thus relates to a method and an apparatus in a paper or board machine for confining a pulp flow coming from the headbox 1, which apparatus comprises at least one deckle part 2 being above the wire which in the operating position is arranged to confine the pulp flow coming from the headbox in the lateral direction in the edge area of the wire 3. The invention is characterised by a combination which comprises a support part 50 impervious to liquid being below the wire 3 and a deckle part 2 into connection with which liquid is brought such that a pressure effect is provided which furthers the sealing between the deckle board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com