Refrigerant Dehumidification System with Variable Condenser Unloading

a dehumidification system and variable technology, applied in the field of refrigerant systems, can solve the problems of difficult control, unsatisfactory instabilities in the refrigerant circuit, and the limited range of applications of condenser bypass alone, and achieve the effect of more reheating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

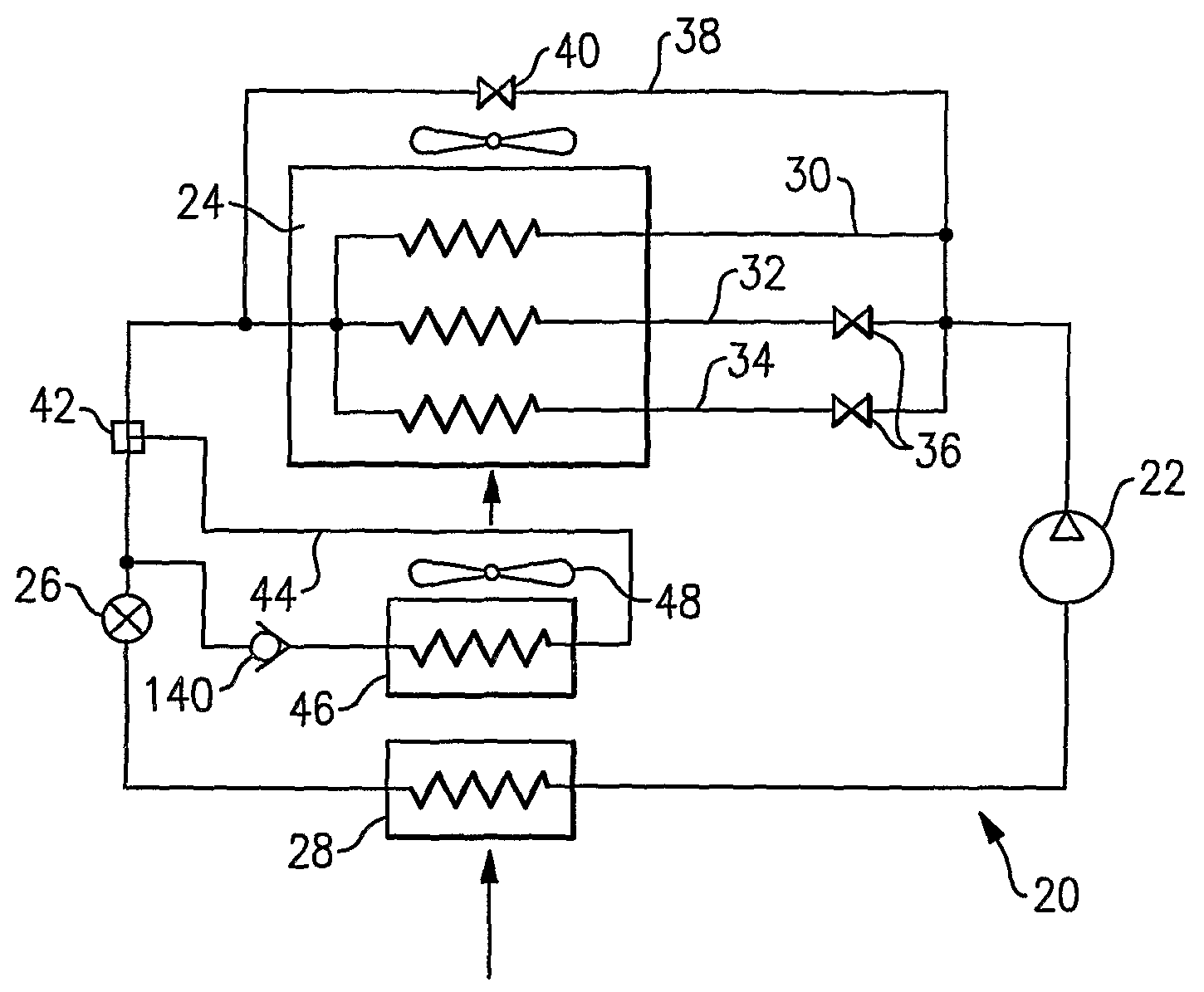

[0012]A refrigerant system 20 is illustrated in FIG. 1 including a compressor 22 compressing refrigerant and delivering it to a downstream condenser 24. An expansion device 26 is located downstream of the condenser 24, and an evaporator 28 is positioned downstream of the expansion device 26. The refrigerant returns from the evaporator 28 to the compressor 22. As shown, a number of parallel refrigerant passages (or circuits) 30, 32 and 34 pass through the condenser 24. Shutoff devices such as valves 36 are placed on two of the three circuits 32 and 34. A control operates to open or close the shutoff valves 36, as will be explained below. A bypass line 38 includes a valve 40 for selectively allowing bypass at least a portion of refrigerant around the condenser 24.

[0013]A three-way valve 42 selectively routes refrigerant into a line 44 and through a reheat heat exchanger 46. A fan 48 pulls air over the evaporator 28 and then over the reheat heat exchanger 46. Also, a check valve 140 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com