Finishing Material Standoff Member For A Structural Support and Installation Method Therefor

a technology of structural supports and finish materials, applied in the direction of walls, covering/linings, building repairs, etc., can solve the problems of unprotected structural supports, which are composed mainly of metals, may be subject to corrosion, labor-intensive and expensive operations, etc., and achieve the effect of efficient, safe and cost-effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

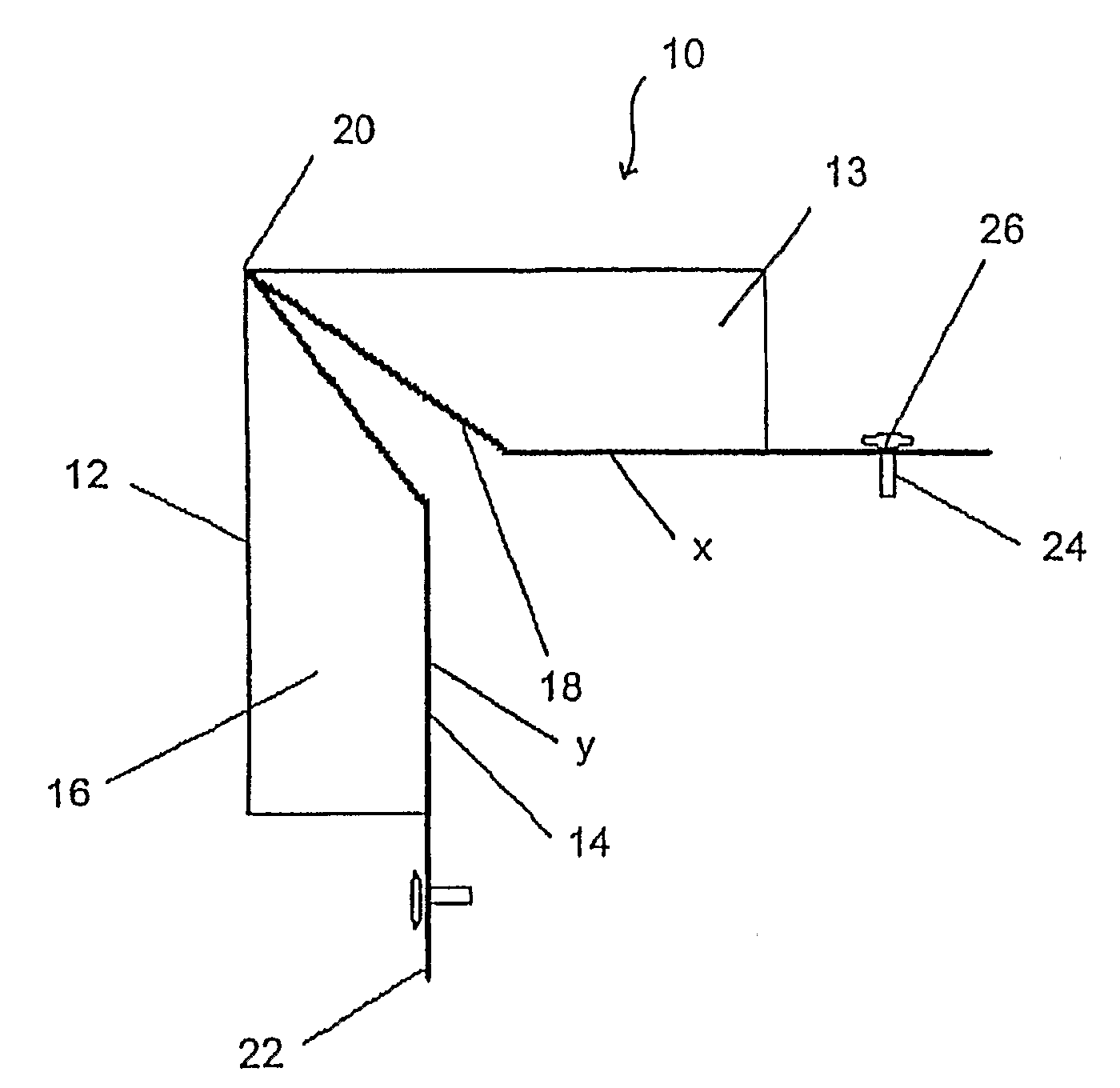

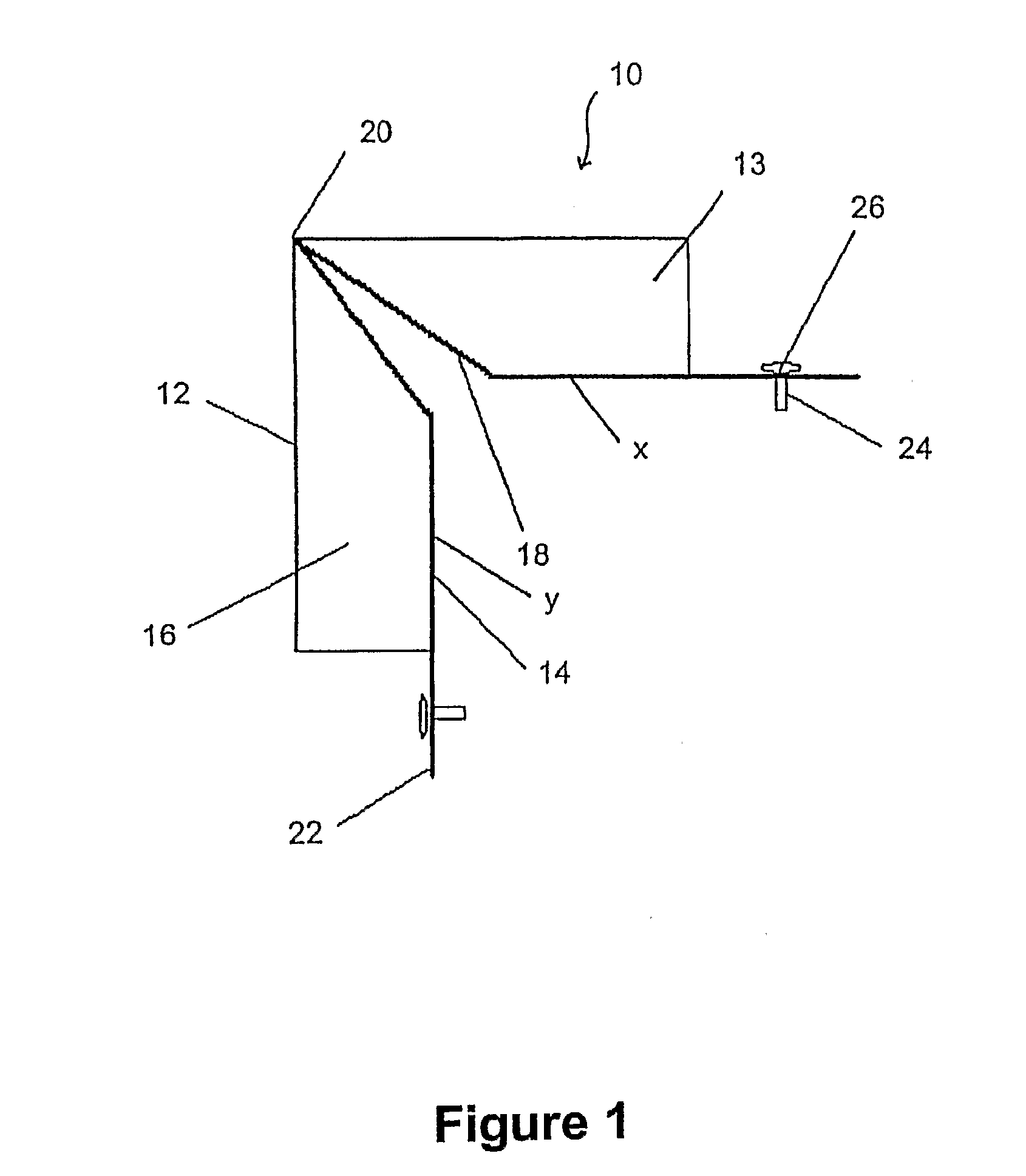

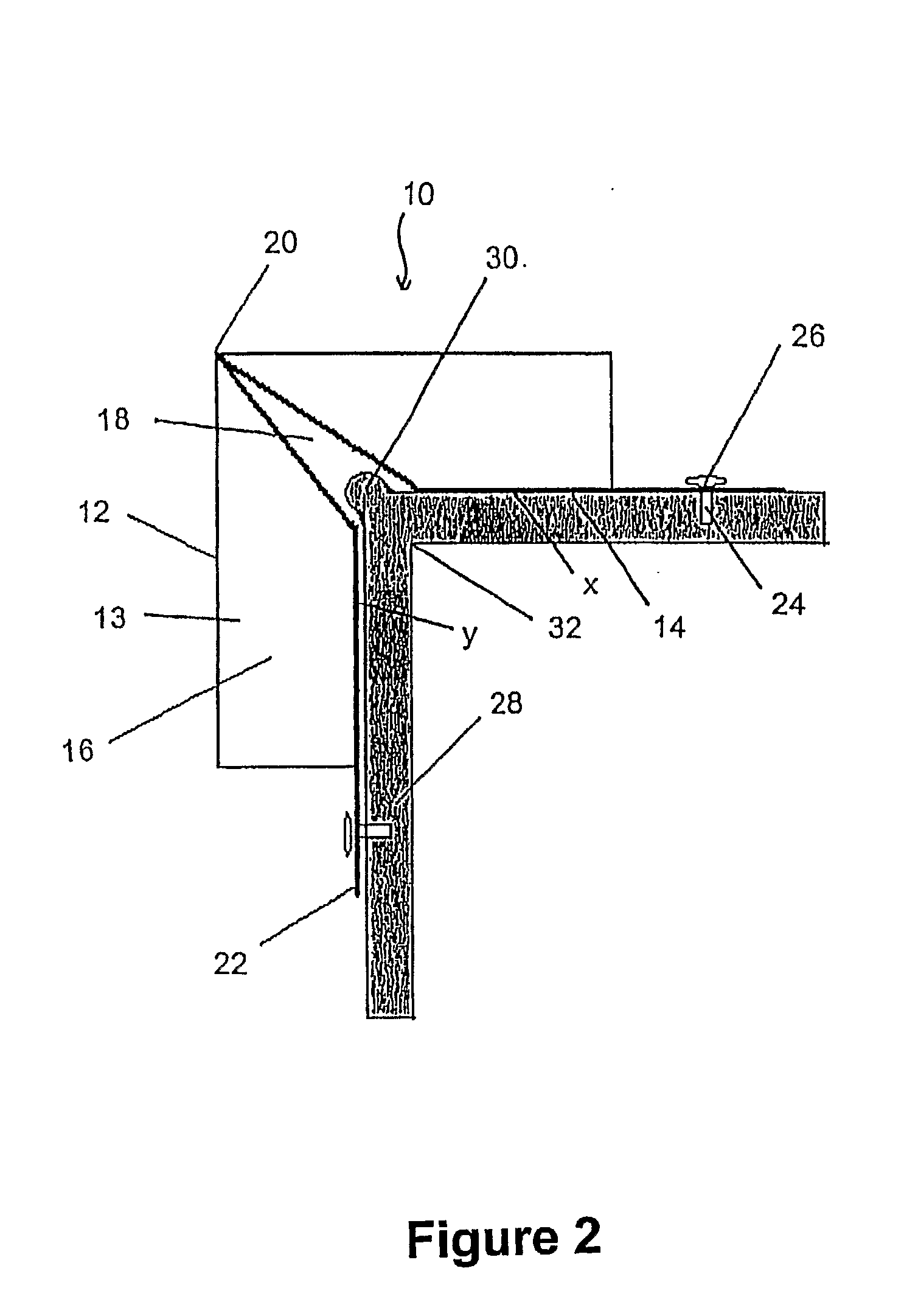

[0028]With reference to the drawings wherein like numerals represent like parts throughout the several Figures, a fastenable standoff member or framing bracket in accordance with the present invention is generally designated by the numeral 10. The fastenable standoff member 10, as shown in FIGS. 1 and 5, includes a finishing material mating surface 12. The finishing material mating surface 12 is transversely spaced apart from a structural support mating surface 14. Between the finishing material mating surface 12 and the structural support mating surface 14 is a finishing material fastener intrusion zone 16. The fastenable standoff member 10 may be formed from sheet metal such as galvanized or stainless steel sheets, and / or from plastic such as glass filled fiber reinforced plastics. In one embodiment, the standoff member 10 is manufactured from 25 gauge galvanized steel. The fastenable standoff member 10 may also be cast, milled, or extruded using materials such as ferrous and non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com