Dishwasher

a technology for dishwashing machines and utensils, which is applied in the field of utensils, can solve the problems of user or child scalding, floor wetness, and hot and humid environment that would make a user feel uncomfortable,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

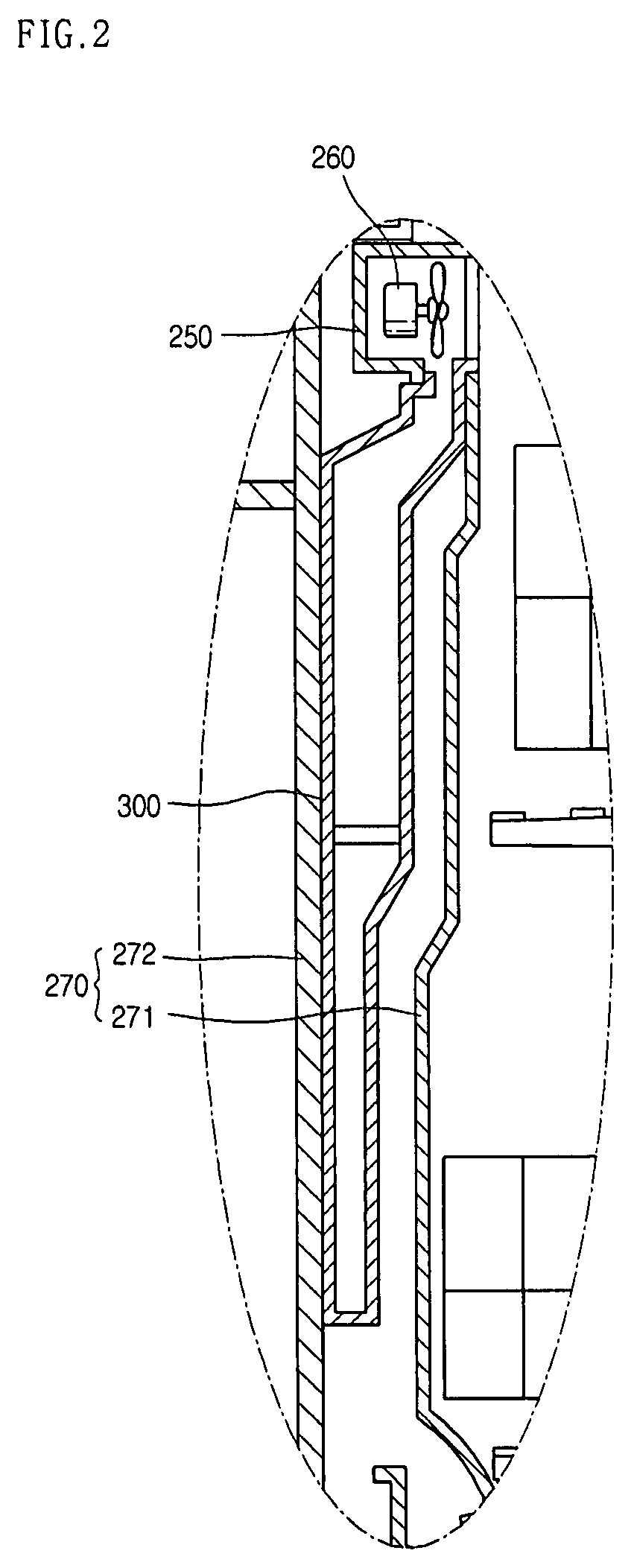

[0071]FIG. 5 is a front view of a door liner of a dishwasher according to the present invention.

[0072]Referring to FIG. 5, the dishwasher includes an outside air guide 280 that is separately provided to suck in outside air.

first embodiment

[0073]In the first embodiment, the steam inside the tub 110 is first condensed and then is mixed with the indoor air sucked in through the outside air guide 280. On the other hand, in this embodiment, the steam inside the tub 110 is mixed with the indoor air sucked in through the outside air guide 280 and then it is condensed.

[0074]In the dishwasher of FIG. 5, a fan assembly is attached to a front side of a door liner 271 to suck in steam from inside the tub 110. A condenser is connected to an outlet 254 of the fan assembly. An outside air guide 280 is connected to one side of the fan assembly to suck in outside air.

[0075]In the first embodiment (FIG. 3), the outside air inlet 255 is formed in a portion of the front surface of the fan housing 250. In this embodiment (FIG. 5), an outside air guide 280 is connected to the outside air inlet 255.

[0076]The outside air guide 280 is separately provided in the front side of the door liner 271, and the outlet is provided under the door 270. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com