Preventive maintenance system and method for fiberglass boats

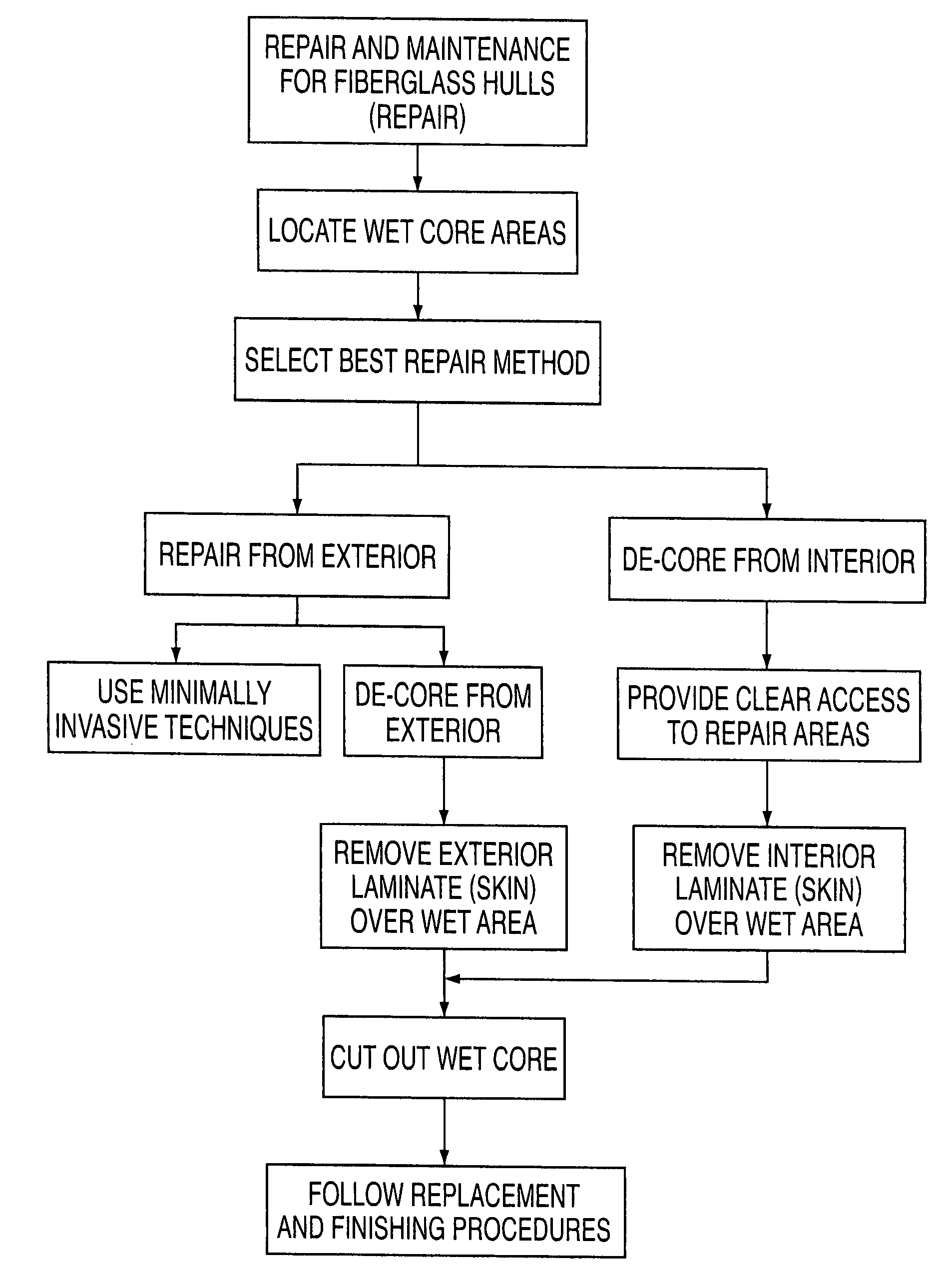

a maintenance system and fiberglass boat technology, applied in the field of preventive maintenance system and method of fiberglass boats, can solve the problems of sporadic regions and spots on the boat, and achieve the effects of reducing the damage to the outer fiberglass skin, preventing further damage, and limiting the labor content of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention has broad applications to many technical fields for a variety of articles. For illustrative purposes only, a preferred mode for carrying out the invention is described herein, wherein a repair system for treating boat hulls with rotted balsa wood cores utilizes a minimally invasive incision and treatment technique of the fiberglass boat hull.

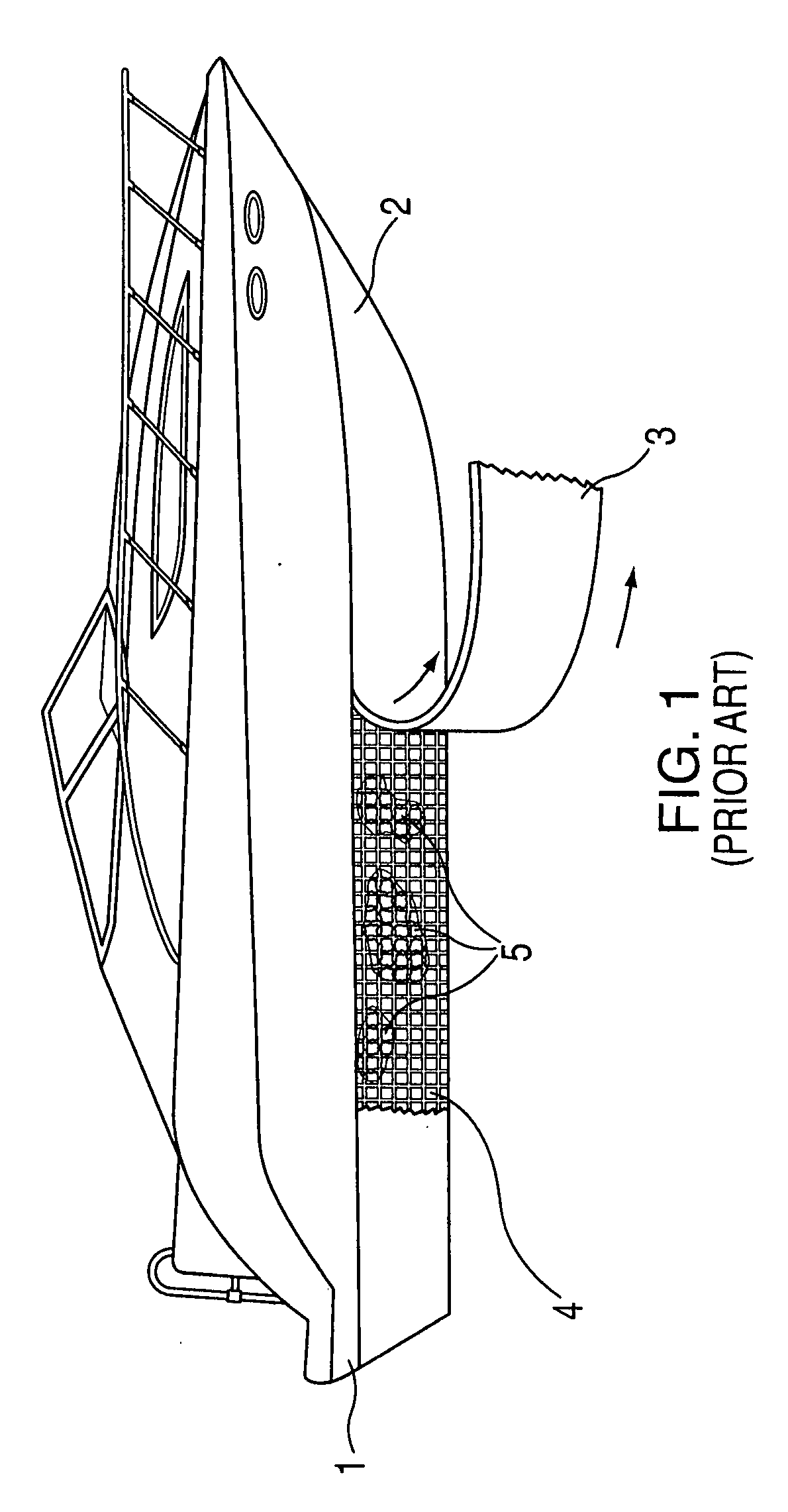

[0089] As shown in FIG. 1, in a prior art boat hull repair method, a major portion of boat hull 1 with a large part of the fiberglass skin 3 is peeled away from fiberglass skin 2, revealing the damaged areas 5 of the balsa wood core of hull portion 4 to be treated and removed.

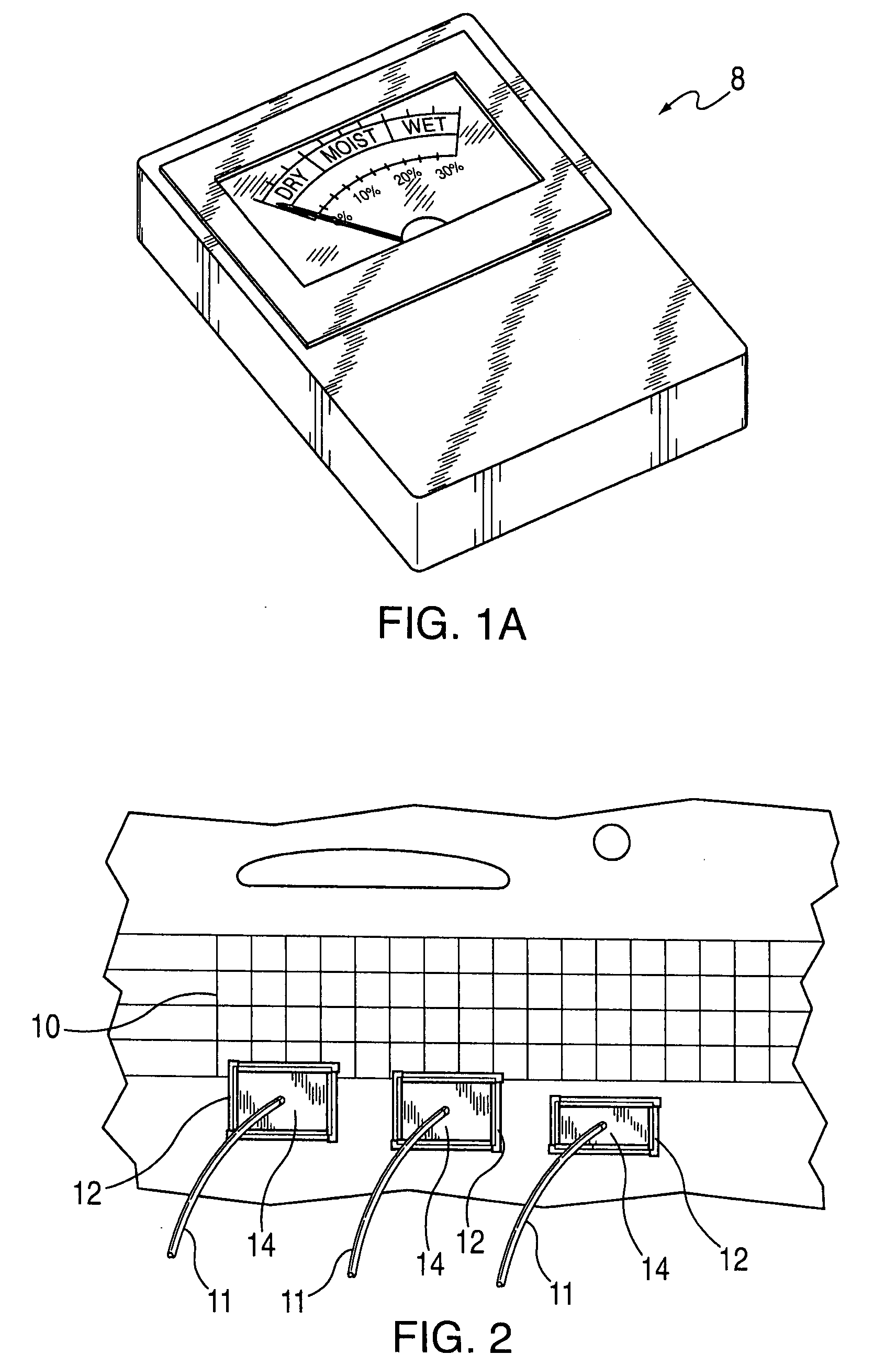

[0090] In contrast, in the present invention, general areas 5 of moisture damage to a boat hull 1 are determined by exposing the exterior surface of a boat hull 1 to a moisture detector 8, such as a moisture meter as shown in FIG. 1A, or by other moisture sensing equipment, such as a thermal or infra-red camera. A typical moisture meter 8 has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com