Combination Silencer

a silencer and combination technology, applied in the field of silencers, can solve the problems of gradual obstructing of the desired sound absorption effect, affecting the acoustic function of the silencer, etc., and achieve the effect of less accumulation of soot and enhanced spark arresting function

Inactive Publication Date: 2008-01-31

SILENTOR HLDG AS

View PDF22 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0037] It will be demonstrated below how the invention makes it possible to attain a significant spark-arresting effect without resorting to design elements that would cause a significant increase of pressure drop across the silencer.

[0038] It will also be demonstrated how the invention can be ad

Problems solved by technology

Although many silencers of known designs, even though not having been designed for such a purpose, will in fact have some spark-arresting effect, a gas flow containing particles, such as exhaust from a diesel engine, may gradually compromise a silencer in its acoustic function.

One important reason for this is that perforations in the walls of such a silencer, allowing noise to be transmitted into sound absorptive material, may in the course of time become clogged, causing the desired sound absorptive effect to become gradually obstructed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

first embodiment

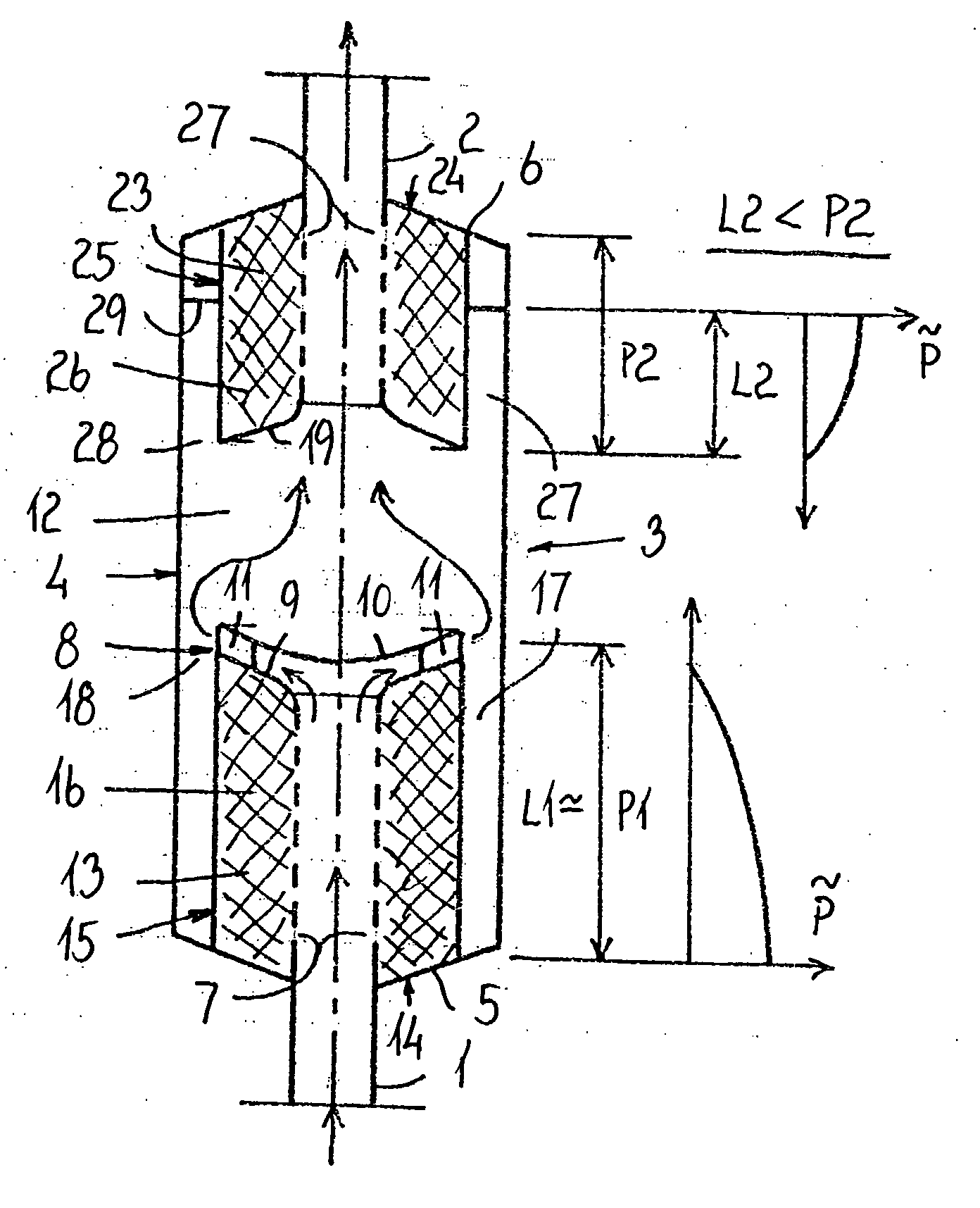

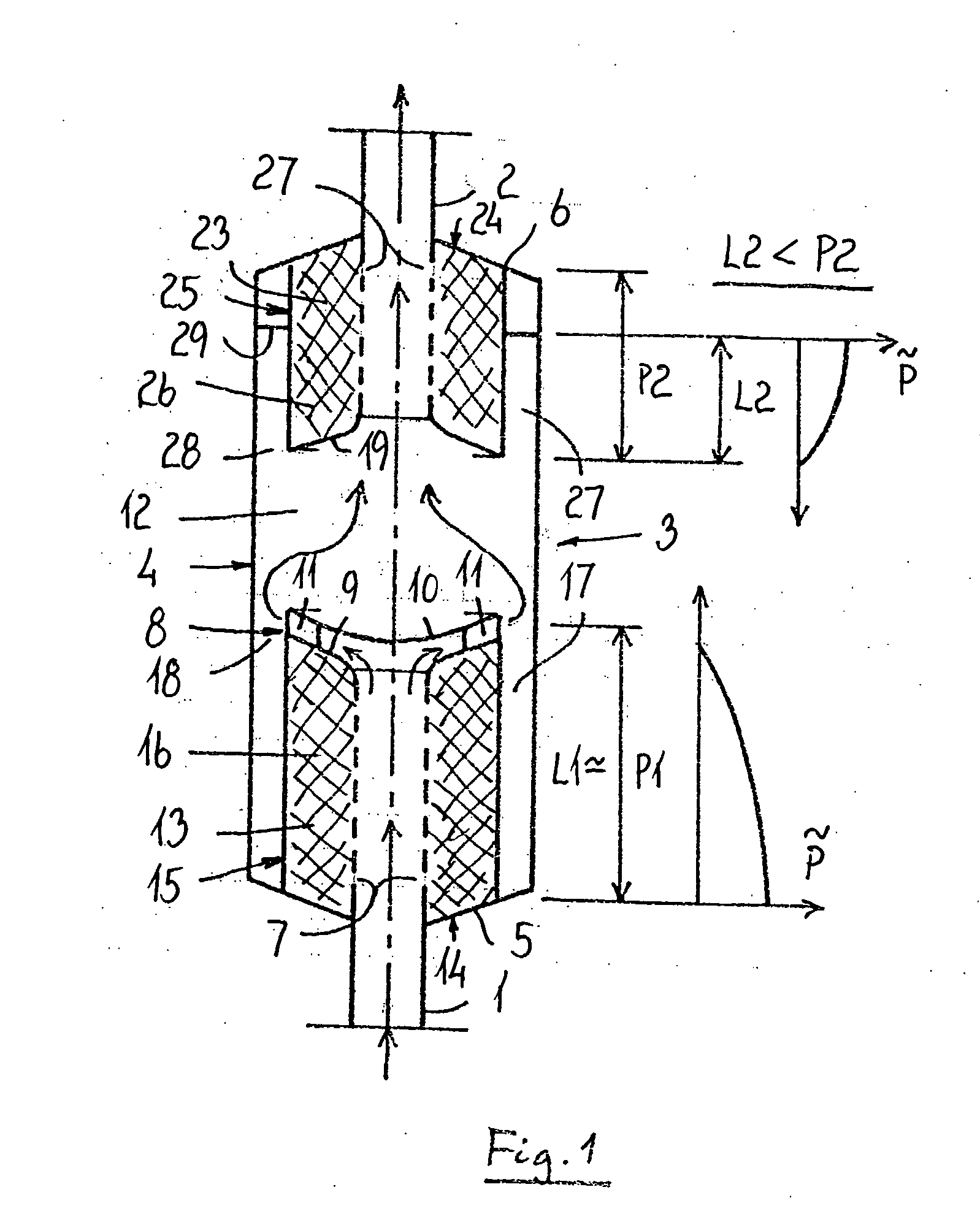

[0040]FIG. 1 shows a longitudinal cross-section of the invention,

second embodiment

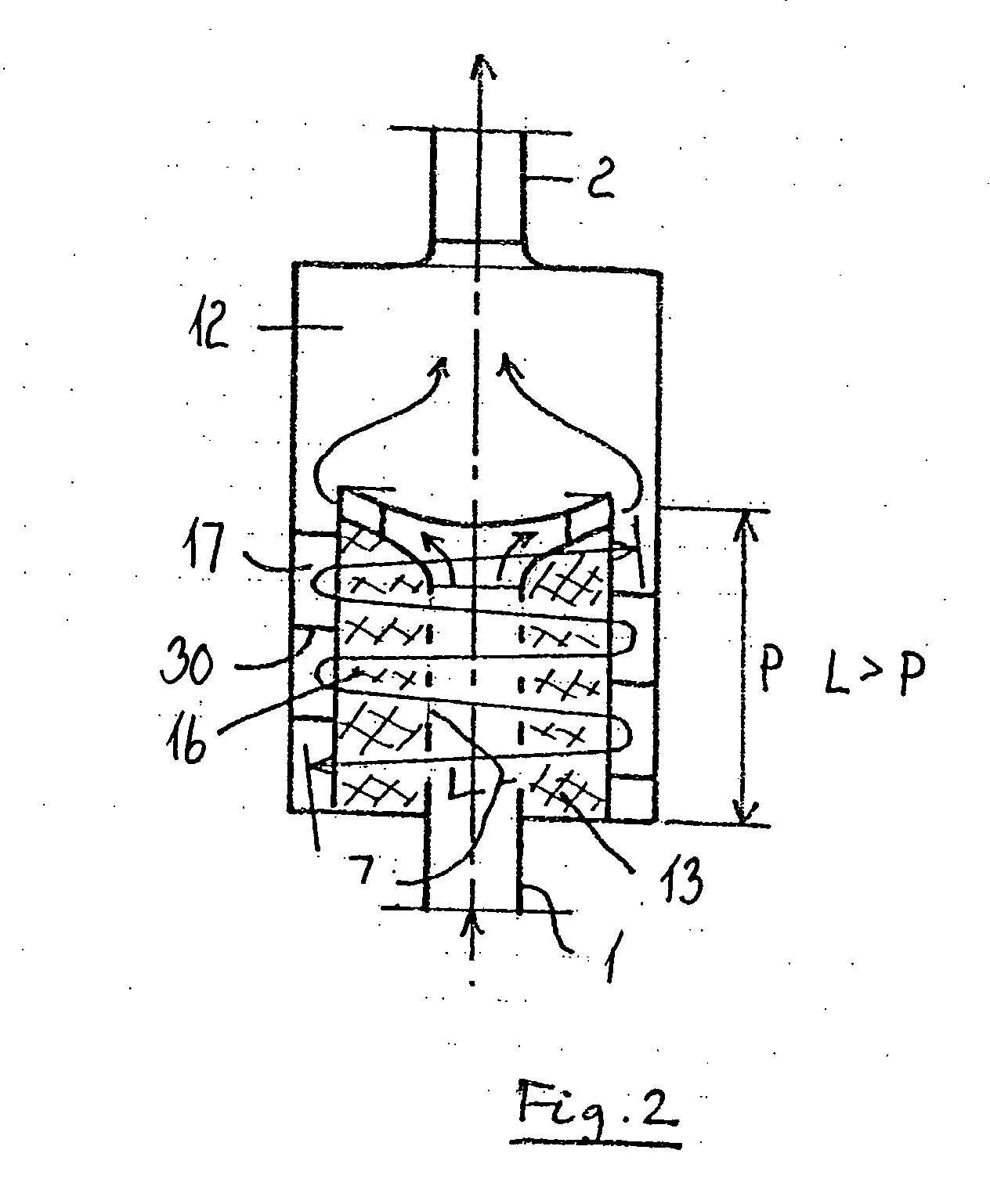

[0041]FIG. 2 shows a longitudinal cross-section of the invention,

third embodiment

[0042]FIG. 3a shows a longitudinal cross-section of the invention,

[0043]FIG. 3b shows a transverse cross-section of the third embodiment of the invention,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a silencer being designed with sound absorptive material (13, 23) and a conduit section (1, 2) with one or more conduits (1) for leading gas flow into the silencer and with one or more outlets (2) for leading gas form the silencer. The sound absorptive material (13, 23) and the conduit section (1, 2) constitutes a protrusion extending from part of an outer shell (4) such as from an end cap (5, 6) constituting part of the shell for the silencer, or from an internal member, such as a baffle (9, 10) possibly separating at least two through-flowed chamber (12) of the silencer. Not-through-flowed cavities (17, 27) are arranged essentially adjacent to or at least partly surrounding said sound absorptive material (13, 23), thereby constituting one or more resonators acoustically communicating with said at least one through-flowed chamber. The silencer may also be designed so as to act as a spark-arrestor. Also, the invention relates to a combustion engine provided with such silencer.

Description

FIELD OF THE INVENTION [0001] The invention relates to a silencer with an outer shell which is provided with one or more inlet conduits for leading a gas into the silencer and with one or more outlet conduits for leading the gas from the silencer. The invention also relates to such a specific silencer designed so as to provide means intended for acting as a spark-arrestor. Furthermore, the invention relates to a combustion engine provided with a silencer according to the invention. BACKGROUND OF THE INVENTION [0002] Reactive silencers for gas flows comprise one or more through-flowed chambers. It is known in the art of silencer design to supplement such silencers in various ways to improve a generally broad-banded noise reduction spectrum at various frequencies. Such improvement is, e.g., warranted because the un-silenced noise spectrum exhibits a peak at one or more frequencies, or because the silencer would otherwise exhibit dips in the attenuation spectrum, typically because of h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F01N1/04F01N1/08F01N1/10F01N3/037

CPCF01N1/04Y02T10/20F01N1/086F01N1/088F01N1/089F01N1/10F01N3/037F01N2210/04F01N2230/06F01N2240/20F01N2470/02F01N2470/14F01N2470/16F01N2470/18F01N2470/20F01N2490/08F01N2490/18F01N1/083Y02T10/12

Inventor FREDERIKSEN, SVENDVALBJORN, PETERMORTENSEN, PREBEN KORNTVED

Owner SILENTOR HLDG AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com